Abstract

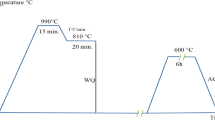

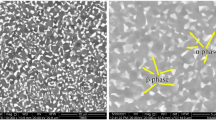

This paper presents the results of a study on the influence of microstructure on the corrosion behavior of a α–β Ti–5%Ta–1.8%Nb alloy—a candidate material for use in high concentrations of boiling nitric acid. The “as cast” alloy had a lamellar structure and showed a corrosion rate of about 1.5 mpy. Thermo-mechanical processing of the cast alloy resulted in a structure of predominantly of equiaxed α with random distribution of fine β particles. This “reference” structure was further modified employing different heat treatments similar to that for commercial titanium alloys such as mill annealing, solution treatment and aging or over aging treatments. Corrosion rates evaluated in boiling nitric acid in the liquid, vapor and condensate phases, showed low values ∼1 mpy. Of these, the lowest corrosion rate (∼0.03 mpy) was exhibited by the structure with minimum amount of β phase, distributed in an equiaxed α matrix. This structure was obtained by aging of the solution treated “reference” alloy. Hence, solution treatment high in the α + β phase field followed by aging at a temperature low in the α + β phase field has been identified as the optimum treatment to obtain a microstructure with superior corrosion resistance.

Similar content being viewed by others

References

Kamachi Mudali U, Dayal RK, Gnanamoorthy JB (1993) J Nucl Mater 203:73

Furuya T, Satoh H, Shimogori K, Nakamura Y, Matsumoto K, Komori Y, Takeda S (1984) In: Proceedings of ANS topical meeting, vol I, p 1.249

Kiuchi K, Hayashi M, Hayakawa H, Sakairi M, Kikuchi M (1994) “Fundamental study of controlling factors on reliability of fuel reprocessing plant materials used in nitric acid solutions”, a poster paper in session: “Corrosion and materials selection”. In: Proceedings of the fourth international conference on nuclear fuel reprocessing and waste management, RECOD ’94, vol III, London, 24–28 April 1994

Ronald WS (1995) In: Baboian R (ed) Corrosion tests and standards: application and interpretation. ASTM manual series: MNL 20. ASTM, Philadelphia, USA, p 493

Steele DF (1986) Atom. March:5

Furuya T, Kawafuku J, Satoh H, Shimogori K, Aoshima A, Takeda S (1991) ISIJ Int 31(2):189

Kiuchi K, Hayakawa H, Takagi Y, Kikuchi M (1994) “New alloy development for fuel reprocessing plant materials used in nitric acid solutions”, a poster paper in session: “Corrosion and materials selection”. In: Proceedings of the fourth international conference on nuclear fuel reprocessing and waste management, RECOD ’94, vol III, London, 24–28 April 1994

Kapoor K, Kain V, Gopal Krishna T, Sanyal T, De PK (2003) J Nucl Mater 322:36

Mythili R, Thomas Paul V, Saroja S, Vijayalakshmi M, Raghunathan VS (2005) Mater Sci Eng A390:299

Mythili R, Saroja S, Vijayalakshmi M, Raghunathan VS (2005) J Nucl Mater 345:167

Ravishankar A, Mythili R, Raju VR, Saroja S, Dayal RK, Vijayalakshmi M, Raghunathan VS, Balasubramaniam R, Singhal LK (2003) In: Raj B, Bhanu Sankara Rao K, Shankar P, Murali N (eds) Proceedings of conference on materials and technologies for nuclear fuel cycle, Chennai, India, 15–16 December 2003, p C-7

Ravi Shankar A (2004) Corrosion behaviour of Ti-5%Ta-1.8%Nb alloy in nitric acid medium for fast reactor fuel reprocessing applications. M. Tech. Thesis, Indian Institute of Technology, Kanpur, India

Bernard C, Mouroux JP (1991) In: Proceedings of the third international conference on nuclear fuel reprocessing and waste management, RECOD ’91, vol II, Sendai, Japan, 14–18 April 1991, p 570

Flower HM (1990) Mater Sci Tech 6:1082

Gill FJ, Genebra MP, Manero JM, Planell JA (2001) J Alloys Compd 329:142

Zhang XD, Bonniwell P, Fraser HL, Baeslack WA III, Evans DJ, Ginter T, Bayha T, Cornell B (2003) Mater Sci Eng A343:210

Publication of Imperial Metal Industries (1969) Corrosion characteristics of titanium in “Corrosion resistance of titanium”, Witton, UK, p 39

Brossia CS, Cragnolino GA (2001) Corrosion 57(9):768

Dull L, Raymond L (1969) J Electrochem Soc 116:332

Lampman S (1987) In: Steven RL, Scott DH (eds) ASM Metals Hand book, vol 2, “Properties & Selection: Non-ferrous Alloys & Special Purpose Materials”, 10th edn. ASM International, Materials Park, OH, USA, p 592

Robin A, Sandim HRZ, Rosa JL (1999) Corr Sci 41:1333

Kenneth RT, Chamberlain J (1988) Corrosion for students of science and engineering. John Wiley and Sons Inc., USA, p 335

Metikos-Hukovic M, Kwokal A (2003) J Piljac, Biomater 24:3765

Williams JC (1973) In: Jaffee RI, Burte HM (eds) Titanium science and technology, vol 3, Plenum Press, New York, p 1433

Ronald WS, David ET (1987) In: Joseph RD, James DD (eds) ASM Metals Handbook, vol 13, “Corrosion”, 9th edn. ASM International, Materials Park, OH, USA, p 669

Pergament AL, Stefanovich GB (1998) Thin Solid Films 322:33

Te-Lin Y (1986) In: Young CS, Durham JC (eds) Industrial applications of titanium, zirconium: vol 4, ASTM STP 917. ASTM, Philadelphia, p 57

Bomberger HB (1984) In: Webster RT, Young CS (eds) Industrial applications of titanium and zirconium: third conference, STP 830. ASTM, Philadelphia, p 143

Khan MA, Williams RL, Williams DF (1996) Biomaterials 17(22):2117

Yu SY, Scully JR (1997) Corrosion 53(12):965

Thair L (2002) Studies on thermomechanically processed and nitrogen ion implanted Ti-6Al-7Nb biomedical alloy. PhD Thesis, Anna University, Chennai, India

Marc Long HJ, Rack H (1998) Biomaterials 19:1621

Sittig C, Textor M, Spencer ND, Wiland M, Vallotton PH (1999) J Mater Sci: Mater Med 10:35

Acknowledgements

The authors wish to acknowledge Dr Baldev Raj, Director, IGCAR, Kalpakkam for his encouragement and keen interest in their pursuit on studies in titanium alloys.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mythili, R., Ravi Shankar, A., Saroja, S. et al. Influence of microstructure on corrosion behavior of Ti–5%Ta–1.8%Nb alloy. J Mater Sci 42, 5924–5935 (2007). https://doi.org/10.1007/s10853-007-1773-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1773-9