Abstract

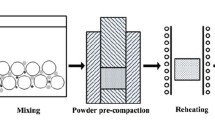

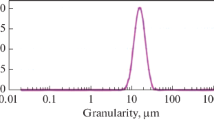

The coefficients of thermal expansion (CTEs) of 20 vol% SiCp/Al composites fabricated by powder metallurgy process were measured and examined from room temperature to 450 °C. The SiC particles are in three nominal sizes 5, 20 and 56μm. The CTEs of the SiCp/Al composites were shown to be apparently dependent on the particle size. That the larger particle size, the higher CTEs of the composites, is thought to be due to the difference in original thermal residual stresses and matrix plasticity during thermal loading. At low temperature, the experimental CTEs show substantial deviation from the prediction of the elastic analysis derived by Kerner and rule of mixture (ROM), while the Kerner’s model agrees relatively well at high temperatures for the composite with the larger particle size.

Similar content being viewed by others

References

Turner PS (1946) J Res Nat Bureau Stand 37:239

Kerner EH (1956) Proc Phys Soc 69 B:808

Eshelby JD (1957) Proc R Soc 241A:376

Lemieux S, Elomari S, Nemes J, Skibo MD (1998) J Mater Sci 33:4381, DOI: 10.1023/A:1004437032224

Shen Y-L, Needleman A, Suresh S (1998) Mater Sci Eng 252A:269

Vogelsang M, Arsenault RJ, Fisher RM (1986) Metall Trans A 17A:379

Arsenault RJ, Shi N (1986) Mater Sci Eng 81:175

Kim CT, Lee JK, Plichta MR (1990) Metall Trans 21A:673

Xu ZR, Chawla KK, Mitra R, Rine ME (1994) Scripta Metall Mater 31:1525

Elomari S, Boukhili R, Marchi S, Mortensen A, Lloyd DJ (1997) J Mater Sci 32:2131, DOI: 10.1023/A:1018535108269

Ma ZY, Bi J, Lu YX et al (1993) In: Miravete A (ed) Proceedings of the ninth international conference on composite materials ICCM/9. vol 1. University of Zaragoza, Madrid, Spain, p 448

Arpón R, Molina JM, Saravanan RA, Gacía-Cordovilla C, Louis E, Narciso J (2003) Acta Mater 51:3145

Kirl S, Hoffman M, Bowman K, Wiederhorn S, Rödel J (1998) Acta Mater 46:2493

Hill R (1950) The mathematical theory of plasticity. Clarendon Press, Oxford

Taya M, Mori T (1987) In: Bui HD, Nguyen DS (eds) Thermomechanical couplings in solids. Elsevier Science, IUTAM, Noth-Holland, pp 147–162

Nakamura T, Suresh S (1993) Acta Metall Mater 41:1665

Shen Y-L, Needleman A, Suresh S (1994) Metall Mater Trans 25A:839

Olsson M, Giannakopoulos AE, Suresh S (1995) J Mech Phys Solids 43:1639

Brooksbank D, Andrews KW (1972) J Iron Steel Inst 249

Kim BG, Dong SL, Park SD (2001) Mater Chem Phys 72:42

Chang SY, Lin SJ, Flemings MC (2000) Metall Trans 31A:291

Isaacs JA, Mortensen A (1992) Metall Trans 23A:1207

Gao H, Huang Y (2001) Int J Solids Struct 38:2615

Arsenlis A, Parks DM (1999) Acta Mater 47:1597

Elomari S, Skibo MD, Sundarrajan A, Richards H (1998) Comp Sci Tech 58:369

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, Y., Geng, L. Effects of particle size on the thermal expansion behavior of SiCp/Al composites. J Mater Sci 42, 6433–6438 (2007). https://doi.org/10.1007/s10853-006-1200-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1200-7