Abstract

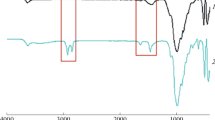

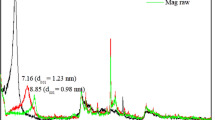

Poly (styrene-acrylonitrile) (SAN)/clay nanocomposites have been prepared by melt intercalation method from pristine montmorillonite (MMT), using hexadecyl trimethyl ammonium bromide (C16) and hexadecyl triphenyl phosphonium bromide (P16) as the reactive compatibilizers between polymer and clay. The influence of the reactive compatibilizers proportion relative to the clay on the structure and properties of the SAN/clay nanocomposites is investigated by X-ray diffraction (XRD) and transmission electron microscopy (TEM), high-resolution electron microscopy (HREM), thermogravimetric analysis (TGA) and dynamic mechanical analysis (DMA). The effects of the two different clays (MMT and organic modified MMT) on the nanocomposites formation, morphology and property are also studied. The results indicate that the SAN cannot intercalate into the interlayers of the MMT and results in microcomposites. In the presence of the reactive compatibilizers, the dispersion of clay in SAN is rather facile and the SAN/clay nanocomposites reveal an intermediate morphology, an intercalated structure with some exfoliation and the presence of small tactoids. The appropriate proportion with 3 wt% reactive compatibilizers to 5 wt% MMT induces well-dispersed morphology and properties in the SAN matrix. The TGA analyses show that the thermal stability properties of the SAN/clay nanocomposites have been improved compared with those of the pristine SAN. The DMA results show that the storage modulus and glass transition temperature (Tg) of the SAN/clay nanocomposites have remarkably enhancements compared with the pristine SAN. At last the intercalation mechanism of the technology is discussed.

Similar content being viewed by others

References

Gilman JW, Jakson CL, Morgan AB, Harris RH, Manias E, Giannelis EP, Wuthenow M, Hilton D, Philips SH (2000) Chem Mater 12:1866

Devaux E, Bourbigot S, El Achari A (2002) J Appl Polym Sci 86:2416

Lan T, Kaviratna PD, Pinnavaia TJ (1994) Chem Mater 6:573

Alexander M, Dubois P (2000) Mater Sci Eng 28:1

Kim TH, Jang LW, Lee DC, Choi HJ, Jhon MS (2002) Macromol Rapid Commun 23:191

Lim ST, Lee CH, Choi HJ, Jhon MS (2003) J Polym Sci Polym Phys 41:2052

Chu LL, Anderson SK, Harris JD, Beach MW, Morgan AB (2004) Polymer 45:4051

Bourbigot S, Vanderhart DL, Gilman JW, Bellayer S, Stretz H, Paul DR (2004) Polymer 45:7627

Bok NJ, Wilie CA (2005) Polymer 46:9702

Stretz HA, Paul DR, Li R, Keskkula H, Cassidy PE (2005) Polymer 46:2621

Kim JW, Choi HJ, Jhon MS (2000) Macromol Symp 155:229

Kim JW, Jang LW, Choi HJ, Jhon MS (2003) J Appl Polym Sci 89:821

Wang HW, Chang KC, Chu HC (2005) Polym Int 54:114

Alexander M, Beyer G, Henrist C, Cloots R (2000) Chem Mater 13:3830

Kawasumi M, Hasegawa N, Kato M, Usuki A, Okada A (1997) Macromolecules 30:6333

Hasegawa N, Kawasumi M, Kato M, Usuki A, Okada A (1998) J Appl Polym Sci 67:87

Noh MH, Jang LW, Lee DC (1999) J Appl Polym Sci 74:179

Vaia RA, Giannels EP (1997) Macromolecules 30:7990

Vaia RA, Teukoisky RK, Giannelis EP (1994) Chem Mater 6:1017

Tang Y, Hu Y, Wang JZ (2004) J Appl Polym Sci 91:2416

Anna CB, Chandralekha S (1998) Macromolecules 31:8370

Yulia L, Anna CB (1998) Macromolecules 31:6676

Valeriy VG, Chandralekha S, Anna CB (2000) Macromolecules 33:1089

Vaia RA, Giannelis EP (1997) Macromolecules 30:8000

Xie W, Xie R, Pan WP, Hunter D, Koene B, Tan LS, Vaia R (2002) Chem Mater 14:4837

Gilman JW, Awad WH, Davis RD, Shields J (2002) Chem Mater 14:3776

Zhu J, Morgan AB, Lamelas FJ, Wilkie CA (2001) Chem Mater 13:3774

Gilman JW, Kashivagi TCL, Giannelis EP, Manias E, Lomakin S, Lichtenhan JD (1998) In: Le Bras M, Caniino G, Bourbigot S, Delobel R (eds) Fire retardancy of polymers. The Royal Society of Chemistry, Cambridge

Choi YS, Xu MZ, Chung IJ (2003) Polymer 44:6989

Choi YS, Choi MH, Wang KH, Kim SO, Kim YK, Chung IJ (2001) Macromolecules 34:8978

Ishida H, Campbell S, Blackwell J (2000) Chem Mater 12:1260

Acknowledgements

The work was financially supported by the National Natural Science Foundation of China (No. 50476026), Specialized Research Fund for the Doctoral Program of Higher Education (20040358056) and Program for New Century Excellent Talents in University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cai, Y., Hu, Y., Xuan, S. et al. Preparation and characterization of poly (styrene-acrylonitrile) (SAN)/clay nanocomposites by melt intercalation. J Mater Sci 42, 5524–5533 (2007). https://doi.org/10.1007/s10853-006-1077-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1077-5