Abstract

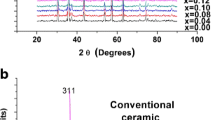

Magnesium ferrite particles consisting of nanocrystallites were synthesized by sol–gel and coprecipitation methods. Their mean crystalline size increased with increasing calcination temperature. At the same calcination temperature, the sol–gel-derived sample always had bigger mean crystalline size than the coprecipitation-derived sample, implying that the sol–gel method facilitated the formation of magnesium ferrite crystallites. Most of the sol–gel-derived magnesium ferrite particles had a lamellar structure consisting of nanocrystallites, which were probably derived from the porous dried gel precursor. The magnesium ferrite particles had superparamagnetic properties at 27 °C, and their saturation magnetization increased with increasing size.

Similar content being viewed by others

References

Chen Q, Zhang ZJ (1998) Appl Phys Lett 73:3156

Oliver SA, Willey RJ, Hamdeh HH, Oliveri G, Busca G (1995) Scripta Metall Mater 33:1695

Chen Q, Rondinone AJ, Chakoumakos BC, Zhang ZJ (1999) J Magn Magn Mater 194:1

Liu C, Zou B, Rondinone AJ, Zhang ZJ (2000) J Am Chem Soc 122:6263

Reddy PV, Satyanarayana R, Rao TS (1984) J Mater Sci Lett 3:847

Benko FA, Koffyberg EP (1986) Mater Res Bull 21:1183

Yang BL, Cheng DS, Lee SB (1991) Appl Catal 70:161

Willey RJ, Noirclerc P, Busca G (1993) Chem Eng Commun 123:1

Xiong C, Chen Q, Lu W, Gao H, Lu W, Gao Z (2000) Catal Lett 69:231

Lee YH, Lee GD, Park SS, Hong SS (2005) React Kinet Catal Lett 84:311

Gusmano G, Montesperelli G, Nunziante P, Traversa E (1993) J Mater Sci 28:6195

Liu Y-L, Liu Z-M, Yang Y, Yang H-F, Shen G-L, Yu R-Q (2005) Sens Actuators B 107:600

Hana SB, Abdel-Mohsen FF, Emira HS (2005) Int Ceram Rev 54:106

Abdel-Mohsen FF, Emira HS (2005) Pigment Resin Technol 34:312

Šepelák V, Baabe D, Litterst FJ, Becker KD (2000) J Appl Phys 88:5884

Šepelák V, Menzel M, Becker KD, Krumeich F (2002) J Phys Chem B 106:6672

Pradhan SK, Bid S, Gateshki M, Petkov V (2005) Mater Chem Phys 93:224

Verma S, Potdar HS, Date SK, Joy PA (2004) In: Glembocki OJ, Hunt CE (eds) Nanoparticles and nanowire building blocks-synthesis, processing, characterization and theory. Materials Research Society, PA, USA, p 83

Huang YJ, Wang J, Chen QW (2005) Chin J Inorg Chem 21:697

Cui H, Zayat M, Levy D (2005) J Sol–Gel Sci Technol 35:175

Yen FS, Chen WC, Yang JM, Hong CT (2002) Nano Lett 2:245

Krupička S, Novák P (1982) In: Wohlfarth EP (ed) Ferromagnetic materials, vol 3. North-Holland Publishing Company, Amsterdam, p 291

Acknowledgements

This research was partially financial supported by the Natural Science Foundation of China (project No. 20476071).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, CP., Li, MW., Cui, Z. et al. Comparative study of magnesium ferrite nanocrystallites prepared by sol–gel and coprecipitation methods. J Mater Sci 42, 6133–6138 (2007). https://doi.org/10.1007/s10853-006-1070-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1070-z