Abstract

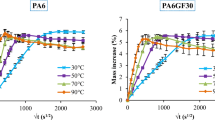

The aim of this study is to evaluate the effect of the humidity on the long term behaviour of glass fiber reinforced thermoplastic in fatigue. Two sets of samples were studied, one set contained 0.2 wt% of water, the second 3.5 wt%. The fatigue tests are performed at a 10 Hz frequency, at room temperature and two various relative humidity ratios, 50% RH and 96% RH. The S–N curve of dried samples (0.2%) is above the one of humid samples (3.5%), the endurance limit at 107 cycles for dried samples is equal to 40 MPa against 35 MPa for the second set. For a given strain, the fatigue life is higher for humid samples because the induced stress is much lower due to the plasticizing effect of water. Though the tests are carried out at room temperature (23 °C), the sample temperature at the surface reaches values higher than Tg and whatever the applied strain, the matrix is in a rubbery state when the fracture occurs. On the basis of S.E.M. examinations, the following scenario is proposed: crack initiation at the fiber end, crack propagation along the fiber sides going with debonding, then crack propagation in the rubbery matrix.

Similar content being viewed by others

References

Trotignon JP, Tcharkhtchi A (1996) Macromol Symp 108:231

Dally JW, Carrillo DH (1969) Polym Eng Sci 9:434

Di Benedetto AT, Salee G (1975) Polym Eng Sci 15:243

Bretz PE, Hertzberg RW, Manson JA (1987) J Mater Sci 22:4015

Horst JJ, Damage 96 Conference, Fukuako, Japan, June 1996

Mark JE (1996) Physical properties of polymers handbook. American Chemical Society

Trotignon JP (1995) Polymer Testing 14:129

Mc Crum NG, Read BE, Williams G (1967) Anelastic and dielectric effects in polymeric solids. Wiley, New York

Papir YS, Kapur S, Rogers CE, Baer E (1972) J Polym Sci A2 10:1305

Wright WW (1981) Composites 12:201

Kohan MI (1973) Nylon plastics. Wiley, New York

Noda K, Takahara A, Kajiyama T (2001) Polymer 42:5803

Van Krevelen DW, Hoftyzer PJ (1976) Properties of polymers, 2nd edn. Elsevier, New York, p 283

Rittel D (2000) Mech Mater 32:131

Rittel D, Eliash N, Halary JL (2003) Polymer 44:2817

Molinari A, Germain Y (1996) Int J Solids 33(23):3439

Chandra R, Singh SP, Gupta K (1999) Compos Struct 46:41

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Barbouchi, S., Bellenger, V., Tcharkhtchi, A. et al. Effect of water on the fatigue behaviour of a pa66/glass fibers composite material. J Mater Sci 42, 2181–2188 (2007). https://doi.org/10.1007/s10853-006-1011-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-1011-x