Abstract

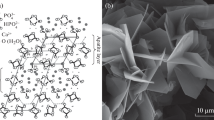

Calcium carbonate is one of the bioceramics and has been used clinically as a bone substitute in dental and orthopedic surgery. Introduction of macropores into the bioceramics is highly recommended because those pores enable tissue ingrowth and accelerated osteointegration. We tried to prepare calcium carbonate body with macropores through the new carbonation method of calcium hydroxide/sodium chloride composite. Sodium chloride acted as a water-soluble porogen in developing macropores in calcium carbonate body and was removed completely by washing with distilled water after carbonation. We investigated effects of sodium chloride content and molding pressure on the porosity and the mechanical strength of the calcium carbonate body. Through this study, it was found that the porosity of body increased with the sodium chloride content in composite and was hardly affected by molding pressure. On the other hand, the mechanical strength was increased with the molding pressure and reduced with the porosity. In addition, the increase in content of sodium chloride caused the enlargement of hole size as well as the enhancement of extent of interconnection among pores through hole. Especially, the calcium carbonate body with over 90% porosity could be prepared when 90 wt.% sodium chloride was used under 10 MPa molding pressure. Its average pore and hole size were 177 and 80 μm, respectively.

Similar content being viewed by others

References

Maeda H, Kasuga T, Nogami M, Ueda M (2005) Sci Technol Adv Mater 6:48

Miao X, Hu Y, Liu J, Wong AP (2004) Mater Lett 58:397

Lemos AF, Ferreira JMF (2000) Mater Sci Eng C 11:35

Engin NO, Tas AC (1999) J Eur Cer Soc 19:2569

Sous M, Bareille R, Rouais F, Clement D, Amedee J, Dupuy B, Baquey C (1998) Biomaterials 19:2147

Piattelli A, Podda G, Scrano A (1997) Biomaterials 18:623

Landi E, Tampieri A, Celotti G, Vichi L, Sandri M (2004) Biomaterials 25:1763

Suetsugu Y, Takahashi Y, Okamura FP, Tanaka J (2000) J Solid State Chem 155:292

Malkaj P, Kanakis J, Dalas E (2004) J Crystal Growth 266:533

Tong H, Ma W, Wang L, Wan P, Hu J, Cao L (2004) Biomaterials 25:3923

Kasuga T, Maeda H, Kato K, Nogami M, Hata K, Ueda M (2003) Biomaterials 24:3247

Manoli F, Kanakis J, Maldaj P, Dalas E (2002) J Crystal Growth 236:363

Girot AL, Langlois P, Sangleboeuf JC, Ouammou A, Rouxel T, Gaude J (2002) Biomaterials 23:503

Li N, Jie Q, Zhu S, Wang R (2005) Cer Int 31:641

Tadic D, Beckmann F, Schwarz K, Epple M (2004) Biomaterials 25:3335

Navarro M, Valle SD, Martinez S, Zeppetelli S, Ambrosio L, Planell JA, Ginebra MP (2004) Biomaterials 25:4233

Almirall A, Larrecq G, Delgado JA, Martinez S, Planell JA, Ginebra MP (2004) Biomaterials 25:3671

Ramay HR, Zhang M (2003) Biomaterials 24:3293

Chang BS, Lee CK, Hong KS, Youn HJ, Ryu HS, Chun SS, Park KW (2000) Biomaterials 21:1291

Bouler JM, Trecant M, Delecrin J, Royer J, Passuti N, Daculsy G (1996) J Biomed Mater Res 32:603

Li SH, Wijn JRD, Layrolle P, Groot KD (2002) J Biomed Mater Res 61:109

Sanders JP, Gallagher PK (2002) Thermochimica Acta 388:115

Lin X, Matsuya S, Udoh KI, Nakagawa M, Terada Y, Ishikawa K (2003) Archives of Bioceramics Research: Asian BioCeramics Symposium, Fukuoka, Japan vol. 3, p. 83

Blom EJ, Nulend JK, Klein CPAT, Kurashina K, Van MAW, Burger EH (2000) J Biomed Mater Res 50:67

Bohner M, Lemaitre J, Van PL, Zambelli P, Merkle H, Gander B (1997) J Pharm Sci 86:565

Otsuka M, Matsuda Y, Suwa Y, Fox J, Higuchi W (1994) J Pharm Sci 83:611

Otsuka M, Matsuda Y, Suwa Y, Fox J, Higuchi W (1994) J Pharm Sci 83:1565

Diamond LW, Akinfiev NN (2003) Fluid Phase Equilib 208:265

Erdal S, Bahar I, Erman B (1998) Polymer 39(10):2035

Elfil H, Roques H (2001) Desalination 137:177

Acknowledgements

This work was supported by both Dankook University(DKU-2004-037) and a Grant-in-aid for Scientific Research from the Ministry of Education, Sports, Culture, Science and Technology, Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, Y., Hahm, Y.M., Matsuya, S. et al. Development of macropores in calcium carbonate body using novel carbonation method of calcium hydroxide/sodium chloride composite. J Mater Sci 42, 5728–5735 (2007). https://doi.org/10.1007/s10853-006-0747-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0747-7