Abstract

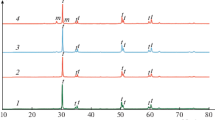

A three phase ceramic composite of 8 mol% Y2O3 stabilized ZrO2 (YSZ), SiO2, and Al2O3 was evaluated for potential high temperature superplasticity. The amorphous SiO2 content was 5 wt.%, and increasing additions of Al2O3 were made. The effect of varying the Y2O3 stabilizer concentration in ZrO2 was also studied. Samples sintered at 1200 °C contained only YSZ, Al2O3, and amorphous SiO2, but ZrSiO4 formed in the samples above 1300 °C. Mullite (3Al2O3 · 2SiO2) was not detected in any samples. Specimens of 1 wt.% Al2O3–YSZ/SiO2 had an anomalously high deformation rate of ∼2 × 10−4 s−1 at 1200 °C when compared to YSZ/SiO2 without Al2O3 (∼4 × 10-5 s−1). Higher amounts of Al2O3 additions decreased the strain rate. Extensive deformation of Al2O3 doped YSZ/SiO2 at 1200 °C induced the formation of ZrSiO4 due to enhanced reaction rates. This distributed, yet locally interconnected, zircon phase rapidly eroded the strain rate after ∼60% deformation.

Similar content being viewed by others

References

Kim BN, Hiraga K, Morita K, Sakka Y (2001) Nature 413:288

Chen I-W, Xue LA (1990) J Am Ceram Soc 73:2585

Morita K, Hiraga K, Kim BN, Sakka Y (2004) Mater Trans 45:2073

Sharif AA, Mecartney ML (2004) J Eur Ceram Soc 24:2041

Suzuki TS, Sakka Y, Morita K, Hiraga K (2000) Scripta Mater 43:705

Kajihara K, Yoshizawa Y, Sakuma T (1995) Acta Metall Mater 43:1235

Sharif AA, Mecartney ML (2003) Acta Mater 51:1633

Dillon RP, Sosa SS, Mecartney ML (2004) Scripta Mater 50:1441

Thompson AW (1972) Metallography 5:366

Ikuhara Y, Yoshida H, Sakuma T (2001) Mater Sci & Eng A A319-321:24

Sakuma T, Ikuhara Y, Takigawa Y, Thavorniti P (1997) Mater Sci & Eng A A234-236:226

Thavorniti P, Ikuhara Y, Sakuma T (1998) J Am Ceram Soc 81:2927

Hassan AAE, Menzler NH, Blass G, Ali ME, Buchkremer HP, Stover D (2002) J Mater Sci 37:3467

Chokshi AH, Yoshida H, Ikuhara Y, Sakuma T (2003) Mater Lett 57:4196

Sakka Y, Ishii T, Suzuki TS, Morita K, Hiraga K (2004) J Eur Cer Soc 24:449

Feighery AJ, Irvine JTS (1999) Solid State Ionics 121:209

Goretta KC, Cruse TA, Koritala RE, Routbort JL, Melendez-martinez JJ, De Arellano-Lopez AR (2001) J Eur Ceram Soc 21:1055

Ondik HM, Mcmurdie HF (eds) (1998) Phase diagrams for zirconium and zirconia systems. The American Ceramic Society, Westerville, p. 254

Kolitsch U, Seifert HJ, Ludwig T, Aldinger F (1999) J Mater Res 14:447

Yaroshenko V, Wilkinson DS (2000) J Mater Res 15:1358

Kanno Y (1989) J Mat Sci 24:2415

Sakka Y, Suzuki TS, Morita K, Nakano K, Hiraga K (2001) Scripta Mater 44:2075

Xue LA, Chen I-W (1992) J Am Ceram Soc 75:1085

Acknowledgements

This work was supported by the National Science Foundation under Grant No. DMR-0207197.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dillon, R.P., Mecartney, M.L. Dynamic formation of zircon during high temperature deformation of zirconia–silica composites with alumina additions. J Mater Sci 42, 3537–3543 (2007). https://doi.org/10.1007/s10853-006-0582-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0582-x