Abstract

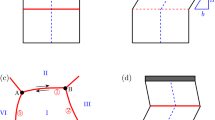

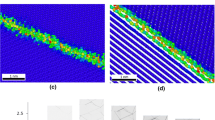

We study the process of grain boundary sliding through the motion of grain boundary dislocations, utilizing molecular dynamics and embedded atom method (EAM) interatomic potentials. For a Σ = 5 [001]{310} symmetrical tilt boundary in bcc Fe, the sliding process was found to occur through the nucleation and glide of partial grain boundary dislocations, with a secondary grain boundary structure playing an important role in the sliding process. While the homogeneous nucleation of these grain boundary dislocations requires shear strain levels higher than 7%, preexisting grain boundary dislocations are shown to glide at applied shear levels of 1.5%. The glide of the dislocations results in coupled motion of the boundary in the directions parallel and perpendicular to itself. Finally, interstitial impurities and vacancies were introduced in the grain boundary to study the effects on the sliding resistance of the boundary. While vacancies and H interstitials act as preferred nucleation sites, C interstitials do not. Both hydrogen and C interstitials stop dislocation glide whereas vacancies do not. A detailed study of the dynamic properties of these dislocations is also presented.

Similar content being viewed by others

References

Van Swygenhoven H, Caro A Farkas D (2001) Scr Materialia 44(8–9):1513

Pond RC, Hirth JP (1994) Solid State Physics – Adv Res Appl 47:287

Van Swygenhoven H, Derlet PA (2001) Phys Rev B 64(22)

Hoagland RG, Kurtz R (2002) Philos Mag A – Phy Cond Matter Struct Defects Mech Prop 82(6):1073

Farkas D, Curtin WA (2005) MSE&A 412(1–2):316

Winning M (2004) Zeitschrift Fur Metallkunde 95(4):233

Kurtz RJ, Hoagland R, Hirth JP (1999) Philos Mag A – Phy Cond Matter Struct Defects Mech Prop 79(3):665

Sheikh Ali AD (1997) Acta Mater 45(8):3109

Sagalowic L, Clark WAT (1996) Interface Sci 4(1–2):29

Bollmann W (1981) Philos Mag A – Phy Cond Matter Struct Defects Mech Prop 43:201

Sansoz F, Molinari JF (2005) Acta Mater 53(7):1931

Dorfman S, Fuks D, Malbouisson LAC, et al (2003) Computational Mater Sci 27(1–2):199

Chandra N, Dang P (1999) J Mater Sci 34(4):655

Bishop GH Jr, Harrison R, Kwok T, Yip S (1982) J Appl Phys 53:5596

King TAH, Smith DA (1980) Acta Crystallogr A 36:335

Wang GJ, Sutton AP, Vitek V (1984) Acta Metallurgica 32(7):1093

Hyde B, Farkas D (2005) Philos Mag 85(32):3795

Geng WT, Freeman AJ, Wu R, Geller CB, Raynolds JE (1999) Phys Rev B 60:7149

Ballo P, Degmova J, Slugen V (2005) Phys Rev B 72(6)

Simonelli G, Pasianot R, Savino EJ (1993) Mater Res Soc 291:567

Ruda M, Farkas D, Abriata J (2002) Scr Materialia 46(5):349

Ruda M, Farkas D, Abriata J (1996) Phy Rev B 54(14):9765

Campbell GH, Kumar M, King WE, et al (2002) Philos Mag A – Phy Cond Matter Struct Defects Mech Prop 82(8):1573

Latapie A, Farkas D (2003) Scr Materialia 48(5):611

Chang JP, Bulatov VV, Yip S (1999) J Computer – Aided Mater Design 6(2–3):165

Chang JP, Bulatov VV, et al (2001) MSE&A 309:160

Cahn JW, Mishin Y, Suzuki A (2006) Philos Mag 86:3965

Acknowledgements

This work was supported by NSF, Materials Theory.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Monk, J., Hyde, B. & Farkas, D. The role of partial grain boundary dislocations in grain boundary sliding and coupled grain boundary motion. J Mater Sci 41, 7741–7746 (2006). https://doi.org/10.1007/s10853-006-0552-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0552-3