Abstract

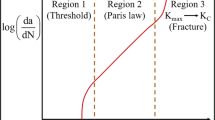

The addition of liquid-filled urea-formaldehyde (UF) microcapsules to an epoxy matrix leads to significant reduction in fatigue crack growth rate and corresponding increase in fatigue life. Mode-I fatigue crack propagation is measured using a tapered double-cantilever beam (TDCB) specimen for a range of microcapsule concentrations and sizes: 0, 5, 10, and 20% by weight and 50, 180, and 460 μm diameter. Cyclic crack growth in both the neat epoxy and epoxy filled with microcapsules obeys the Paris power law. Above a transition value of the applied stress intensity factor ΔK T, which corresponds to loading conditions where the size of the plastic zone approaches the size of the embedded microcapsules, the Paris law exponent decreases with increasing content of microcapsules, ranging from 9.7 for neat epoxy to approximately 4.5 for concentrations above 10 wt% microcapsules. Improved resistance to fatigue crack propagation, indicated by both the decreased crack growth rates and increased cyclic stress intensity for the onset of unstable fatigue-crack growth, is attributed to toughening mechanisms induced by the embedded microcapsules as well as crack shielding due to the release of fluid as the capsules are ruptured. In addition to increasing the inherent fatigue life of epoxy, embedded microcapsules filled with an appropriate healing agent provide a potential mechanism for self-healing of fatigue damage.

Similar content being viewed by others

References

Cardoso RJ, Shukla A, Bose A (2002) J Mater Sci 37:603

Bagheri R, Pearson RA (1996) J Mater Sci 31:4529

Skibo MD, Hertzberg RW, Manson JA, Kim SL (1977) J Mater Sci 12:531

Paris PC, Gomez MP, Anderson WE (1961) The Trend in Engineering at the University of Washington 13:9

Karger-Kocsis J, Friedrich K (1993) Compos Sci Technol 48:263

Nagasawa M, Kinuhata H, Koizuka H, Miyamoto K, Tanaka T, Kishimoto H, Koike T (1995) J Mater Sci 30:1266

McMurray MK, Amagi S (1999) J Mater Sci 34:5927

Becu L, Maazouz A, Sautereau H, Gerard JF (1997) J Appl Polym Sci 65:2419

Rey L, Poisson N, Maazouz A, Sautereau H (1999) J Mater Sci 34:1775

Hayes BS, Seferis JC (2001) Polym Compos 22:451

Azimi HR, Pearson RA, Hertzberg RW (1996) Polym Eng Sci 36:2352

Azimi HR, Pearson RA, Hertzberg RW (1995) J Appl Polym Sci 58:449

Sautereau H, Maazouz A, Gerard JF, Trotignon JP (1995) J Mater Sci 30:1715

Azimi HR, Pearson RA, Hertzberg RW (1996) J Mater Sci 31:3777

Brown EN, White SR, Sottos NR (2004) J Mater Sci 39:1703

White SR, Sottos NR, Geubelle PH, Moore JS, Kessler MR, Sriram SR, Brown EN, Viswanathan S (2001) Nature 409:794

Brown EN, Sottos NR, White SR (2002) Exp Mech 42:372

Kessler MR, Sottos NR, White SR (2003) Composites Part A 34:743

Brown EN, Kessler MR, Sottos NR, White SR (2003) J Microencapsul 20:719

Brown EN (2003) In: Fracture and Fatigue of a self-healing polymer composite material, PhD dissertation, University of Illinois at Urbana-Champaign

Rzeszutko AA, Brown EN, Sottos NR (2004) 2003 Proceedings of 5th Undergraduate Research Conf. in Mechanics, University of Illinois at Urbana-Champaign, TAM Report No. 1041, 27

Mostovoy S, Crosley PB, Ripling EJ (1967) J Mater 2:661

Wang WZ, Li CT, Ye FX (2004) Vacuum 73:649

Blackman BRK, Hadavinia H, Kinloch AJ, Paraschi M, Williams JG (2003) Engng Fract Mech 70:233

Macon DJ, Anderson GL (2002) J Appl Polym Sci 86:1821

Beres W, Koul AK, Thambraj R (1997) J Test Eval 25:2419

Cammino R, Gosz M, Mostovoy S (2000) In: Proceedings of ASME International Congress and Exposition 415:17

Kessler MR (2002) In: Characterization and performance of a self-healing composite material, PhD dissertation, University of Illinois at Urbana-Champaign

Saxena A, Hudak SJ Jr (1978) Int J Fract 14:453

Karger-Kocsis J, Friedrich K (1992) Colloid Polym Sci 270:549

Chudnovsky A, Kim A, Bosnyak CP (1992) Int J Fract 55:209

Irwin GR (1960) Proceedings of 7th Sagamore Ornance Mater. Res. Conf. 4:63

Xiao K, Ye L, Kwok YS (1998) J Mater Sci 33:2831

Araki W, Adachi T, Gamou M, Yamaji A (2002) Proc I Mech E Part L 216:79

Endo K, Okada T, Komai K, Kiyota M (1972) Bull Japan Soc Mech Eng 15:1316

Galvin G, Naylor H (1964) Proc Inst Mech Eng J 179:56

Plumbridge WJ, Ross PJ, Parry JSC (1985) Mater Sci Eng 68:219

Polk C, Murphy W, Rowe C (1975) ASLE Transactions 18:290

Acknowledgments

The authors gratefully acknowledge support from the AFOSR Aerospace and Materials Science Directorate Mechanics and Materials Program (Award No. F49620-00-1-0094), the National Science Foundation (NSF CMS0218863), and Motorola Labs, Motorola Advanced Technology Center, Schaumburg Ill. Any opinions, findings, and conclusions or recommendations expressed in this publication are those of the authors and do not necessarily reflect the views of the AFOSR or Motorola Labs. The authors would also like to thank Profs. J.S. Moore and P.H. Geubelle of the Autonomic Materials Laboratory of the Beckman Institute of Advanced Science and Technology and Dr. A. Skipor of Motorola Labs for technical support and helpful discussions. Electron microscopy was performed in the Imaging Technology Group, Beckman Institute, of the University of Illinois at Urbana-Champaign, with the assistance of S. Robinson. LAUR-04-2668.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brown, E.N., White, S.R. & Sottos, N.R. Fatigue crack propagation in microcapsule-toughened epoxy. J Mater Sci 41, 6266–6273 (2006). https://doi.org/10.1007/s10853-006-0512-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0512-y