Abstract

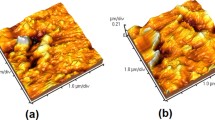

In this work, the interfacial response of a glass-based coating on Ti6Al4V to monotonic and cyclic Hertzian (spherical) indentation is investigated. This coating belongs to the SiO2-CaO-MgO-Na2O-K2O-P2O5 system and it is specifically designed to be used as the inner layer of a bioactive bilayer coating with an outer layer of lower SiO2 content to ensure bioactivity. During Hertzian monotonic loading, delamination of the coating occurs, which is revealed in the microscope by the presence of a colour pattern of interference fringes at the interface. Hertzian cyclic loading at maximum loads, P max, lower than the monotonic delamination load, P Del, also generates delamination damage. A plot of P max versus the number of cycles for delamination shows a two-slope curve with a “knee” for P max close to the critical load to induce a radial crack from the interface, P Rc. The analysis of the delamination morphology and the results for different load ratios, R = P min/P max, confirmed the existence of two different delamination mechanisms with a common feature of plastic deformation of the substrate but with a different dependence with the maximum applied load: for P max > P Rc the process is mostly controlled by the presence of the radial cracks (P max dependent), meanwhile, for P max < P Rc radial cracks are not observed and delamination is attributed to the residual stress at the interface induced by the cyclic plastic deformation of the substrate and the elastic recovery of the coating during unloading part.

Similar content being viewed by others

References

Hench L (1991) J Am Ceram Soc 74:1487

Ducheyne P, Hench L, Kagan A, Martens M, Burssens A, Muller JC (1980) J Biomed Mater Res 14:225

Xue W, Tao S, Liu X, Zheng XB, Ding C (2004) Biomaterials 25:415

Gu YW, Khor KA, Cheang P (2003) Biomaterials 24:1603

Lacefield WR (1993) An introduction to bioceramics. World Scientific, Singapore, p 223

Chern Lin JH, Shen KS, Ju CP (1995) Mater Chem Phys 41:82

Hench L, Anderson Ö (1993) An introduction to bioceramics. World Scientific, Singapore, p 239

Donald IW (1993) J Mater Sci 28:2841

Gómez-Vega JM, Saiz E, Tomsia AP (1999) J Biomed Mater Res 46:549

Pazo A, Saiz E, Tomsia AP (1998) Acta Mater 46:2551

Pazo A, Saiz E, Tomsia AP (1998) Ceramic microstructures: control at atomic level. Plenum Press, Berkeley, p 543

Hench L, Splinter RJ, Allen WC, Greenlee TK (1971) J Biomed Res Symp 2:117

Brunski JB (1992) Clinic Mater 10:153

Lawn BR (2002) Curr Opin: Solid State Mater Sci 6:229

DeLong R, Douglas WH (1983) J Dent Res 62:32

Eberhardt AW, Lewis JL, Keer LM (1991) ASME J Biomed Eng 113:410

Lopez-Esteban S, Saiz E, Fujino S, Oku T, Suganuma K, Tomsia AP (2003) J Eur Ceram Soc 23:2921

Oku T, Suganuma K, Wallenberg LR, Tomsia AP, Gomez-Vega JM, Saiz E (2001) J Mat Sci: Mat Med 12:413

Huber MT (1904) Ann Phys (Leipzig) 43:153

Miranda P (2003) Diseño de Materiales Multicapa Resistentes al Daño por Contacto, Ph.D. Thesis. Universidad de Extremadura, p 150

Frank FC, Lawn BR (1967) Proc R Soc Lond A 299:291

Warren PD (1995) J Eur Ceram Soc 15:201

Chai H, Lawn BR, Wuttiphan SJ (1999) J Mat Res 9:3805

Rhee YW, Kim HW, Deng Y, Lawn BR (2001) J Am Ceram Soc 84:1066

Fisher-Cripps AC, Lawn BR, Pajares A, Wei L (1996) J Am Ceram Soc 79:2619

Hecht E, Zajac A (1974) Optics. Addison-Wesley, Massachusetts, p 293

Pavón J, Jiménez-Piqué E, Anglada M, Saiz E, Tomsia AP (2006) Acta Mater, in press

Suresh S (1998) Fatigue of materials. Cambridge University Press, Cambridge, p 113

Ritchie RO (1999) Int J Fract 100:55

McNaney JM, Cannon RM, Ritchie RO (1996) Acta Mater 44:4713

Acknowledgements

This work is supported by the Spanish Ministry of Science and Technology through Grant No. MAT202-00368, the Generalitat de Catalunya through the Gaspar de Portolà exchange program, and the National Institutes of Health/National Institutes of Dental and Craniofacial Research through Grant No. IR01DE11289. The authors would like to thank specially Dr. Luis Llanes for valuable discussion. Finally, J. Pavón wishes to thank Colciencias-Colombia for financial sponsorship of his Ph.D. studies.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pavón, J., Jiménez-Piqué, E., Anglada, M. et al. Delamination under Hertzian cyclic loading of a glass coating on Ti6al4v for implants. J Mater Sci 41, 5134–5145 (2006). https://doi.org/10.1007/s10853-006-0439-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0439-3