Abstract

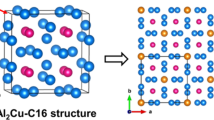

Experiments to investigate interfacial heat transfer mechanisms during casting solidification were carried out by varying the surface roughness of a Cu chill used to bring about unidirectional solidification of an Al-4.5 wt.% Cu alloy. Little variation in interfacial heat transfer coefficient with varying chill surface roughness was found, confirming previously published results. Examination of the as-cast surface of the casting showed the presence of predendritic contact areas, and also that the casting surface roughness did not form as a replica of the chill surface, as has often been proposed. Rather, the casting surface roughness was consistently greater than that of the chill, but varied little in the experiments. A sum surface roughness parameter was devised to characterise the casting–chill interface that included the roughness of both surfaces. The value of this parameter was strongly influenced by the greater roughness of the casting surface, rather than the chill surface roughness, and therefore also varied little in the experiments. This lack of variation in the casting surface roughness and hence the sum surface roughness parameter showed how interfacial heat transfer should be more strongly influenced by the greater roughness of the casting surface than of the chill surface, and explains why the interfacial heat transfer coefficient was not strongly influenced by the chill surface roughness in these types of experiments.

Similar content being viewed by others

References

Madhusadana CV (1996) Thermal contact conductance. Springer, New York

Muojekwu CA, Samarasekera IV, Brimacombe JK (1995) Met Mat Trans B 26B:361

Assar AM (1997) Mat Sci Technol 13:702

Wang G-X, Matthys EF (2002) Int J Heat Mass Trans 45:4967

Loulou T, Artyukhin EA, Bardon JP (1999) Int J Heat Mass Trans 2129

Griffiths WD (1999) Met Mat Trans B 30B:473

Hallam CP, Griffiths WD (2004) Met Mat Trans 35B:721

Kayikci R (2000) PhD Thesis, UMIST

Biloni H, Chalmers B (1965) Trans Met Soc (AIME) 233:373

Prates M, Biloni H (1972) Met Trans 3:1501

Ho K, Pehlke RD (1984) AFS Trans 92:587

Ho K, Pehlke RD (1985) Met Trans B 16B:359

Dong S, Niyama E, Anzai K, Matsumoto N (1993) Cast Metals 6:115

Sharma DGR, Krishnan M (1991) AFS Trans 99:429

Acknowledgements

The authors gratefully acknowledge Federal-Mogul Corporation (WDG) and Sakarya University, Turkey (RK) for financial support of a Senior Research Fellowship and a Research Studentship respectively.

Author information

Authors and Affiliations

Corresponding author

Additional information

At the time the work was carried out the authors were in the Manchester Materials Science Centre, University of Manchester and UMIST, Manchester M1 7HS, UK.

Rights and permissions

About this article

Cite this article

Griffiths, W.D., Kayikci, R. The effect of varying chill surface roughness on interfacial heat transfer during casting solidification. J Mater Sci 42, 4036–4043 (2007). https://doi.org/10.1007/s10853-006-0388-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0388-x