Abstract

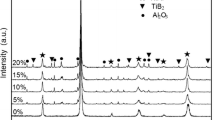

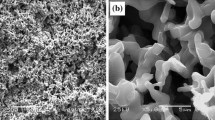

Porous material of TiB2 with improved mechanical properties was fabricated by vacuum and pressureless sintering. The microstructure of the porous ceramic was characterized by the enhanced neck growth between the initially touching particles. This neck growth was ascribed to the selective heating of TiB2 particles with different dimension. The porous structure prepared by the high-temperature sintering exhibited higher bending strength and fracture toughness in the present experiment. The improved mechanical properties of the sintered composites were attributable to the enhanced neck growth by surface diffusion.

Similar content being viewed by others

References

Peng HX, Fan Z, Evans JRG, Busfield JJC (2000) J Eur Ceram Soc 20:807

Corbin SF, Apte PS (1999) J Am Ceram Soc 82(7):1693

Oh ST, Tajima KI, Ando M, Ohji T (2000) J Am Ceram Soc 83(5):1314

Fukasawa T, Ando M, Ohji T, Kanzaki S (2001) J Am Ceram Soc 84(1):230

Hardv D, Green DJ (1995) J Eur Ceram Soc 15:769

Oh S-T, Tajima Ken-ichi, Ando M, Ohji T (2001) Mater Lett 48:215

Oh Ik-Hyum, Nomura N, Masahashi N, Hanada S ( 2003) Scripta Materialia 49:1197

She JH, Ohji T (2003) Mater Chem Phys 80:610

Toby M, Peter Mathews G, Hugget S (1999) Powder Technol 104:169

She J, Yang J-F, Konda N (2002) J Am Ceram Soc 85(11):2852

Zhen-Yan D, Yang J-F, Beppu Y (2002) J Am Ceram Soc 85(8):1961

Deng ZY, Fukasawa T, Ando M, Zhang GJ, Ohji T (2001) Acta Materialia 49(11):1939

Fang Y, Agrawal DK, Roy DM (1992) J Mater Res 7(2):490

Bhaumik SK, Divakar C, Singh AK, Upadhyaya GS (2000) Mater Sci Eng A 279:275

Weimin Wang, Zhengyi Fu (2002) J Eur Ceram Soc 22:1045

Zhen-Yan D, She J, Inagaki Y (2004) J Eur Ceram Soc 24:2055

Walker WJ Jr, Reed JS, Verma SK (1999) J Am Ceram Soc 82:50

Flinn BD, Bordia RK, Zimmermann A, Rodel J (2000) J Eur Ceram Soc 20:2561

Acknowledgements

This work was supported by the program for NCTE and the National Natural Science Foundation of China (Project No. 90505015). We would also show thanks the support of the Foundation of National Key Laboratory for Remanufacturing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hong, C., Zhang, X., Han, J. et al. Fabrication and mechanical properties of porous TiB2 ceramic. J Mater Sci 41, 4790–4794 (2006). https://doi.org/10.1007/s10853-006-0040-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0040-9