Abstract:

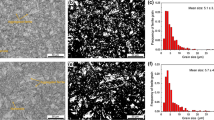

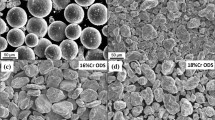

In order to investigate the formation, distribution, growth behavior and volume fraction of porosity at high temperatures in ferritic Oxide Dispersion Strengthened (ODS) superalloys MA 956, ODM 751 and PM 2000 were exposed at 1100 and 1200∘C in air and in 2% oxygen containing nitrogen atmospheres for up to 8760 h. All samples exhibited small amounts of porosity (% < 0.1) in the as-received condition. During the early stages of exposure (up to 10 h) pores were generally located close to the surface of the samples. Later they were found in the central region of the samples and the volume fraction of porosity and the mean pore size increased. After exposure for 240–1000 h, mainly depending on sample thickness, the size and volume fraction of porosity reached a maximum value and then decreased. SEM and EDS analysis results showed that some pores contained small amounts of Ti, Al and Y rich particles which were distributed over the internal surface of pores. It was noted that when the volume fraction of porosity and the size of pores began to decrease the pores had filled with the matrix material. A relation was established between the production environment of the materials and the growth behavior of the pores.

Similar content being viewed by others

References

M. TURKER, Corros. Sci. 4-1/1 (1999) 1.

M. TURKER, H. CAMA and T. A. HUGHES, Corros. Sci. 37 (1995) 413.

A. H. ROSENSTEIN, J. K. TIEN and W. D. NIX, Met. Trans. 17A (1986) 151.

M. TURKER and T. A. HUGHES, in Proceedings of the 2nd International Conference on Microscopy of Oxidation (Cambridge, March 1993) p. 301.

G. KORB, in Proceedings of Conference on New Materials by MA Techniques, edited by E. Artz and L. Schultz (Calw-Hirasu, 1989) p. 175.

J. H. WEBER and P. S. GILMAN, Scripta Metallurgia 18 (1984) 479.

J. J. STHEPENS and W. D. NIX, Met. Trans. 16A (1985) 1307.

P. HANCOCK, in Proceedings of Conference on Vacancies’76, Bristol, edited by R. E. Smallman and J. E. Harris (Bristol University Met. Soc., 1976) p. 215.

J. KOMENDA and P. J. HENDERSON, Scripta Materialia 37 (1997) 1821.

M. J. BENNETT, H. ROMARY and J. B. PRICE, in Proceedings of Conference on Heat Resistance Materials (Fortana, Wisconsin, September 1991) p. 95.

H. D. HENDRICH, in Proceedings of Conference on New Materials by MA Techniques, edited by E. Artz and L. Schultz (Calw-Hirasu, 1988) p. 217.

M. TURKER and T. A. HUGHES, Oxidation of Metals 44 (1995) 505.

J. RITHERDON and A. R. JONES, Mat. at High Tem 18 (2001) 177.

H. D. HENDRICK, in “High Temperature Materials for Power Engineering” Part 1 (1990) p. 789.

Y. L. CHEN and A. R. JONES, Met. Mater. Trans. A 32A (2001) 2077.

P. K. SUNG, D. R. POIRIER, S. D. FELICELLI, E. J. POIRIER and A. AHMED, J. Crystal Growth 226 (2001) 363.

Y. L. CHEN, A. R. JONES and U. MILLER, Met. Mater. Trans. A 32A (2002) 2713.

M. TURKER, in Ph.D Thesis, University of Leeds School of Materials, UK, 1993.

M. TURKER, “8th International Metallurgy and Materials Congress” (Istanbul, Turkey, 1995) p. 161.

F. STARR, Private Communication (British Gas London Research Station).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Turker, M. Formation of porosity in ferritic ODS alloys on high temperature exposure. J Mater Sci 40, 1201–1208 (2005). https://doi.org/10.1007/s10853-005-6938-9

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-6938-9