Abstract

The carbon-coated composite has been manufactured and investigated as the negative electrode for Li-ion batteries. The carbon-coated composite powders are prepared by a simple mixing of two types of synthetic graphite particles (SFG6 and SFG44) with polyvinylchloride powders and heating to a temperature between 800 and 1100°C under an argon gas flow.

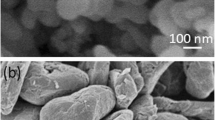

As a result of the carbon-coating treatment, the flake particles of the original graphites changed into a bulky shape of carbon-coated composite with a largely increased particle size due to aggregation through the treatment. It is shown that carbon-coated composite electrodes for the two types of graphite have much lower irreversible loss than the original graphites and coulombic efficiency of ∼91% in the first cycle in a PC-based electrolyte. The carbon coating treatment improves the cycling performance. Despite their coarse morphology due to aggregation, carbon-coated composite electrodes show the enhanced high rate capabilities.

Similar content being viewed by others

References

K. Guerin, A. Fevrier-Bouvier, S. Flandrois, M. Couzi, B. Simon and P. Biensan, J. Electrochem. Soc. 146 (1999) 3660.

H. Azuma, H. Imoto, S. Uamada and K. Sekai, J. Power Sources 81/82 (1999) 1.

Q. Liu, T. Zhang, C. Bindra, J. E. Fischer and J. Y. Josefowicz, ibid. 68 (1997) 287.

M. Winter, P. Novak and A. Monnier, J. Electrochem. Soc. 145 (1998) 428.

H. Nakamura, H. Komatsu and M. Yoshio, J. Power Sources 62 (1996) 219.

W. Xing and J. R. Dahn, J. Electrochem. Soc. 144 (1997) 1195.

P. Yu, J. A. Ritter, R. E. White and B. N. Popov, ibid. 147 (2000) 1280.

I. Kuribayashi, M. Yokoyama and M. Yamashita, J. Power Sources 54 (1995) 1.

M. Yoshio, H. Wang, K. Fukuda, Y. Hara and Y. Adachi, J. Electrochem. Soc. 147 (2000) 1245.

Z. X. Shu, R. S. Mcmillan, J. S. Murray and I. J. Davidson, ibid. 142 (1995) L161.

G. H. Wrodnigg, T. M. Wrodnigg, J. O. Besenhard and M. Winter, Electrochem. Commun. 1 (1999) 148.

H. Y. Lee, J. K. Baek, S. W. Jang, S. M. Lee, S. T. Hong, K. Y. Lee and M. H. Kim, J. Power Sources 101 (2001) 206.

G. C. Chung, H. J. Kim, S. I. Yu, S. H. Jun, J. W. Choi and N. H. Kim, J. Electrochem. Soc. 147 (2000) 4391.

G. C. Chung, S. H. Jun, K. Y Lee and M. H. Kim, ibid. 146 (1999) 1664.

K. Zaghib, G. Nadeau and K. Kinoshita, ibid. 147 (2000) 2110.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baek, JK., Lee, HY., Jang, SW. et al. Electrochemical performance of modified synthetic graphite for lithium ion batteries. J Mater Sci 40, 347–353 (2005). https://doi.org/10.1007/s10853-005-6089-z

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-6089-z