Abstract

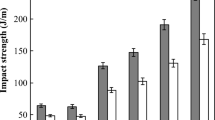

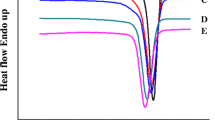

Nylon6 is an attractive polymer for engineering applications because it has reactive functionality through amine and carboxyl end groups that are capable of reacting. For this reason, it has been used a lot in polymeric blends. Blends of nylon6/ABS (acrylonitrile-butadiene-styrene) were produced using glycidyl methacrylate-methyl methacrylate (GMA-MMA) copolymers as compatibilizer. The binary blends were immiscible and exhibited poor mechanical properties that stemmed from the unfavorable interactions among their molecular segments. This produced an unstable coarse phase morphology and weak interfaces between the phases in the solid state. The presence of the copolymer in the blends clearly led to a more efficient dispersion of the ABS phase and consequently optimized Izod impact properties. However, the compatibilized blend showed poor toughness at room temperature and failed in a brittle manner at subambient temperatures.

Similar content being viewed by others

References

E. M. ARAÚJO, PhD thesis, Universidade Federal de São Carlos, São Carlos, Brazil, (2001).

V. J. TRIACCA, S. ZIAEE, J. W. BARLOW, H. KESKKULA and D. R. PAUL, Polymer 32 (1991) 1401.

Y. AOKI and M. WATANABE, Polym. Eng. Sci. 32 (1992) 878.

R. A. KUDVA, H. KESKKULA and D. R. PAUL, Polymer 39 (1998) 2447.

B. MAJUMDAR, H. KESKKULA and D. R. PAUL, ibid. 35 (1994) 3164.

Idem., Polym. Prepr. 35 (1994) 850.

Idem., J. Polym. Sci.: Part B: Polymer Phys. 32 (1994) 2127.

E. HAGE JR., W. R. HALE, H. KESKKULA and D. R PAUL, Polymer 38 (1997) 3237.

S. P. JANG and D. KIM, Polym. Eng. Sci. 40 (2000) 1635.

B. MAJUMDAR. H. KESKKULA and D. R. PAUL, Polymer 35 (1994) 5453.

Idem., ibid. 35 (1994) 5468.

A. MISRA, G. SAWHNEY and R. A. KUMAR, J. Appl. Polym. Sci. 50 (1993) 1179.

R. A. KUDVA, H. KESKKULA and D. R. PAUL, Polymer 40 (1999) 6003.

E. M. ARAÚJO, E. HAGE JR. and A. J. F. CARVALHO, J. Mater. Sci. 38 (2003) 3515.

Idem., ibid. 39 (2004) 1173.

W. R. HALE, H. KESKKULA and D. R. PAUL, Polymer 40 (1999) 4237.

S. H. GOH and S. Y. LEE, J. Appl. Polym. Sci. 41 (1990) 1391.

J. H. KIM, H. KESKKULA and D. R. PAUL, ibid. 40 (1990) 183.

Y. HUANG, Y. LIU and C. ZHAO, ibid. 69 (1998) 1505.

J. BRANDRUP and E. H. IMMERGUT, “Polymer Handbook” 2nd ed. (John Wiley & Sons, New York, 1989).

Y. P. KHANNA, Macromolecules 25 (1992) 3298.

B. C. BONSE, PhD thesis, Universidade Federal de São Carlos, São Carlos, Brazil, 1999.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jo, E.M.A., Hage, E. & Carvalho, A.J.F. Morphological, mechanical and thermal properties of nylon 6/ABS blends using glycidyl methacrylate-methyl methacrylate copolymers. J Mater Sci 40, 4239–4246 (2005). https://doi.org/10.1007/s10853-005-2842-6

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-2842-6