Abstract

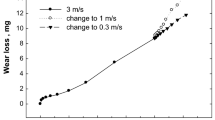

In a concerned tribological system, mechanical behavior such as friction and wear, microstructural evolution, and change in environmental temperature impact each other. A complete understanding of these interactions between the above factors is important for a tribological system to function well. In this study, the relationships among the wear rate, the frictional surface temperature, the heat consumption, and the friction energy consumption of steel 52100 with different microstructures during dry sliding were investigated using wear tests and theoretical approaches. The experimental results showed that the wear rate depends strongly on the thermal physical properties of the different microstructures due to their different energy consumptions during sliding. The calculations based on a frictional temperature field model were consistent with the experimental observations.

Similar content being viewed by others

References

S. C. LIM and M. F. ASHBY, Acta Metall. 35 (1987) 1.

T. F. J. QUINN, Wear 153 (1992) 179.

Y. WANG, T. C. LEI, M. F. YAN and C. Q. GAO, J Phys. D: Appl. Phys. 25 (1992) A165.

H. CZICHOS, “Tribology” (Elsevier, Amsterdam, 1992).

F. E. JR. KENNEDY, Wear 100 (1984) 453.

K. KNOTHE and S. LIEBELT, ibid. 189 (1995) 91.

D. A. RIGNEY and W. A. GLAESER, “Wear of Materials” (ASME, New York, 1977) p. 41.

K. H. ZUM-GAHR, “Microstructures and Wear of Materials” (Elsevier, Amsterdam, 1987).

J. KALOUSEK, K. M. FEGREDO and E. E. LAUFFR, Wear 105 (1985) 199.

Y. WANG, L. PAN and T. C. LEI, ibid. 143 (1991) 57.

N. C. WELSH, Phil. Trans. R. Soc. Ser. A 257 (1965) 31.

Idem., ibid. 257 (1965) 51.

Y. WANG, M. F. YAN, X. D. LI and T. C. LEI, Trans. ASME J. Tribol. 116 (1994) 255.

Y. WANG, M. MCNALLAN, X. ZHANG and T. C. LEI, Scripta Mater. 36 (1997) 213.

M. O. ROBBINS and J. KRIM, MRS Bulletin 23(6) (1998) 23.

D. A. RIGNEY and L. E. HAMMERBERG, ibid. 23(6) (1998) 32.

Y. WANG, X. D. LI and Z. C. FENG, Scripta Mater. 33 (1995) 1163.

M. F. ASHBY and S. C. LIM, Scr. Metall. Mater. 24 (1990) 805.

M. F. ASHBY, J. ABULAWI and H. S. KONG, Tribology Trans. 34 (1991) 577.

Y. WANG, X. L. SUN, S. L. XU and J. J. LIU, Wear 162–164 (1993) 183.

Y. S. TOULOUKIAN, “Thermophysical Properties of Matter, The TPRC Data Series,” Specific Heat (IFI/Plenum, New York-Washington, 1970)) Vol. 4.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, W., Wang, Y. & Yan, M.F. Wear rate, frictional temperature, and energy consumption of steel 52100 with different microstructures during sliding. J Mater Sci 40, 5635–5640 (2005). https://doi.org/10.1007/s10853-005-1508-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-005-1508-8