Abstract

This paper considers a closed loop supply chain with the manufacturer as the Stackelberg leader. The manufacturer faces three different reverse channels, i.e., (1) manufacturer-managed, (2) retailer-managed, or (3) third party-managed channels. The reference price affects the purchase decision of consumers. Based on game theory, we discuss the reference price effect on the performances across three decentralized reverse channels, and examine the impact of reference price parameter (i.e., reference price coefficient in this paper) on optimal strategies. We conclude that higher reference price coefficient results in lower manufacturer and retailer profits. However, the profit of the third party increases in the reference price coefficient. In addition, some meaningful insights can be derived by comparison without the reference price effect in our models. We found that the scenario without reference price effect is generally superior to that with reference price effect.

Similar content being viewed by others

Notes

According to Ferrer and Swaminathan (2010) and the official definition of Caterpillar Company, remanufacturing is a process, wherein used products are disassembled, and their parts are cleaned, tested, and repaired. The finished remanufactured products have the same function and life cycle as the manufactured ones. Most importantly, they can enjoy the same after-sales service. The remanufactured product in Caterpillar is labeled the sign “remanufactured.” In practice, however, single-use cameras from Eastman Kodak Company do not label the sign “remanufactured.” Therefore, the assumption (1) is relatively reasonable.

In real world, the investment of advertising for a manufacturer will be conducted before distributing the new product to produce more potential customers. In the light of psychological knowledge, in this case, the customers may have a reference price higher than the manufacturing cost. Hence, assumption (2) is also compatible with the real life.

Throughout this paper, the pronoun “she” denotes the manufacturer. The pronoun “he” denotes all the other supply chain members.

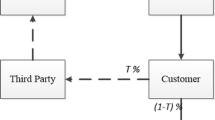

Note that there are three lines in Fig. 1. The dotted line represents the third party-managed channel \((3P)\), whereas the dashed line represents the manufacturer-managed channel \((M)\) and the continuous line represents retailer-managed channel \((R)\), respectively. Hence, in Corollary 1, we pay attention to the dashed line. i.e., \(M\)-managed channel \((M)\). Accordingly, we focus on the continuous line, the doted line in Corollaries 2 and 3, respectively.

References

Atasu, A., Sarvary, M., & Van Wassenhove, L. N. (2008). Remanufacturing as a marketing strategy. Management Science, 54(10), 1731–1746.

Atasu, A., Toktay, L. B., & Van Wassenhove, L. N. (2013). How collection cost structure drives a manufacturer’s reverse channel choice. Production and Operations Management, 22(5), 1089–1102.

Benchekroun, H., Martín-Herrán, G., & Taboubi, S. (2009). Could myopic pricing be a strategic choice in marketing channels? A game theoretic analysis. Journal of Economic Dynamics and Control, 33(9), 1699–1718.

Cheng, C. Y., & Prabhu, V. (2013). An approach for research and training in enterprise information system with RFID technology. Journal of Intelligent Manufacturing, 24(3), 527–540.

Dickson, P. R., & Sawyer, A. G. (1990). The price knowledge and search of supermarket shoppers. The Journal of Marketing, 54(3), 42–53.

Feng, Y. D. (2010). Caterpillar: Remanufacturing can be self-promotive. Business Watch Magazine, 14(8), 80–81.

Ferguson, M. E., & Toktay, L. B. (2006). The effect of competition on recovery strategies. Production and Operations Management, 15(3), 351–368.

Ferrer, G., & Swaminathan, J. M. (2006). Managing new and remanufactured products. Management Science, 52(1), 15–26.

Ferrer, G., & Swaminathan, J. M. (2010). Managing new and differentiated remanufactured products. European Journal of Operational Research, 203(2), 370–379.

Fibich, G., Gavious, A., & Lowengart, O. (2003). Explicit solutions of optimization models and differential games with nonsmooth (asymmetric) reference-price effects. Operations Research, 51(5), 721–734.

Fine, C. H., & Porteus, E. L. (1989). Dynamic process improvement. Operations Research, 37(4), 580–591.

Fleischmann, M., Beullens, P., Bloemhof-Ruwaard, J. M., & Van Wassenhove, L. N. (2001). The impact of product recovery on logistics network design. Production and Operations Management, 10(2), 156–173.

Fleischmann, M., Bloemhof-Ruwaard, J. M., Dekker, R., van der Laan, E., Van Nunen, J. A. E. E., & Van Wassenhove, L. N. (1997). Quantitative models for reverse logistics: A review. European Journal of Operational Research, 103(1), 1–17.

Fleischmann, M., Krikke, H. R., Dekker, R., & Flapper, S. D. P. (2000). A characterization of logistics networks for product recovery. Omega, 28(6), 653–666.

Greenleaf, P. K., & Winer, R. S. (1996). A dynamic model of reference price and expected quality. Marketing Letters, 7(1), 41–52.

Guide, V. R. D., Jayaraman, V., Srivastava, R., & Benton, W. C. (2000). Supply chain management for recoverable manufacturing systems. Interfaces, 30(3), 125–142.

Huang, C. C., Liang, W. Y., Tseng, T. L., & Chen, P. H. (2014). The rough set based approach to generic routing problems: Case of reverse logistics supplier selection. Journal of Intelligent Manufacturing. doi:10.1007/s10845-014-0913-8.

Huang, M., Song, M., Lee, L. H., & Ching, W. K. (2013). Analysis for strategy of closed-loop supply chain with dual recycling channel. International Journal of Production Economics, 144(2), 510–520.

Inderfurth, K., de Kok, A. G., & Flapper, S. D. P. (2001). Product recovery in stochastic remanufacturing systems with multiple reuse options. European Journal of Operational Research, 133(1), 130–152.

Jung, K. S., & Hwang, H. (2011). Competition and cooperation in a remanufacturing system with take-back requirement. Journal of Intelligent Manufacturing, 22(3), 427–433.

Kalwani, M. U., Yim, C. K., Rinne, H. J., & Sugita, Y. A. (1990). Price expectations model of customer brand choice. Journal of Marketing Research, 27(3), 251–262.

Kopalle, P. K., Rao, A. G., & Assuncao, J. L. (1996). Asymmetric reference price effects and dynamic pricing policies. Marketing Science, 15(1), 60–85.

Kumar, V. V., Liou, F. W., Balakrishnan, S. N., & Kumar, V. (2013). Economical impact of RFID implementation in remanufacturing: A chaos-based interactive artificial bee colony approach. Journal of Intelligent Manufacturing. doi:10.1007/s10845-013-0836-9.

Majumder, P., & Groenevelt, H. (2001). Competition in remanufacturing. Production and Operations Management, 10(2), 125–141.

Naeem, M. A., Dias, D. J., Tibrewal, R., Chang, P. C., & Tiwari, M. K. (2013). Production planning optimization for manufacturing and remanufacturing system in stochastic environment. Journal of Intelligent Manufacturing, 24(4), 717–728.

Popesu, I., & Wu, Y. (2007). Dynamic pricing strategies with reference price effects. Operations Research, 55(3), 413–429.

Qiang, Q., Ke, K., Anderson, T., & Dong, J. (2013). The closed-loop supply chain network with competition, distribution channel investment, and uncertainties. Omega, 41(2), 186–194.

Savaskan, R. C., Bhattacharya, S., & Van Wassenhove, L. N. (2004). Closed-loop supply chain models with product remanufacturing. Management Science, 50(2), 239–252.

Shi, Y., Nie, J., Qu, T., Chu, L. K., & Sculli, D. (2013). Choosing reverse channels under collection responsibility sharing in a closed-loop supply chain with remanufacturing. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-013-0797-z.

Souza, G. C. (2013). Closed-loop supply chains. In L. S. Gass & C. M. Fu (Eds.), Encyclopedia of operations research and management science (pp. 169–176). New York: Springer.

Subramanian, P., Ramkumar, N., Narendran, T. T., & Ganesh, K. (2013). PRISM: PRIority based SiMulated annealing for a closed loop supply chain network design problem. Applied Soft Computing, 13(2), 1121–1135.

Takahashi, K., Doi, Y., Hirotani, D., et al. (2012). An adaptive pull strategy for remanufacturing systems. Journal of Intelligent Manufacturing,. doi:10.1007/s10845-012-0710-1.

Wang, J. (2006). Lenovo company has used-computer recycling service. http://news.jinghua.cn. (Accessed December 26, 2006).

Xin, W. (2011). ArvinMeritor: The leader of global commercial vehicle parts remanufacturing industry. Automobile & Parts, 30(25), 22.

Zhang, J., Chiang, W. Y. K., & Liang, L. (2014). Strategic pricing with reference effects in a competitive supply chain. Omega, 44, 126–135.

Zhang, J., Gou, Q., Liang, L., & Huang, Z. (2013). Supply chain coordination through cooperative advertising with reference price effect. Omega, 41(2), 345–353.

Zhang, Y., Jiang, P., Huang, G., Qu, T., Zhou, G., & Hong, J. (2012). RFID-enabled real-time manufacturing information tracking infrastructure for extended enterprises. Journal of Intelligent Manufacturing, 23(6), 2357–2366.

Zied, H., Sofiene, D., & Nidhal, R. (2014). Joint optimization of maintenance and production policies with subcontracting and product returns. Journal of Intelligent Manufacturing, 25(3), 589–602.

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article is available at http://dx.doi.org/10.1007/s10845-015-1038-4.

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Xu, J., Liu, N. Research on closed loop supply chain with reference price effect. J Intell Manuf 28, 51–64 (2017). https://doi.org/10.1007/s10845-014-0961-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-014-0961-0