Abstract

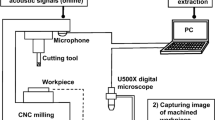

This paper presents a new tool wear monitoring method based on auto associative neural network. The main advantage of the model lies that it can be built only by the data under normal cutting condition. Therefore, the training samples of the tool wear status are no longer needed during the training process that makes it easier to be applied in real industrial environment than other neural network models. An averaged distance indicator is proposed to denote not only the occurrence of the tool wear but also its severity. Moreover, the Levenberg–Marquardt (LM) training algorithm is introduced to improve the convergence accuracy of the auto associative neural network. Based on the proposed method, a framework for online tool condition monitoring is illustrated and the cutting force data under different tool wear status are collected to simulate the online modeling and monitoring process for the rough and finish milling respectively. The results show that the proposed indicator can reflect the evolution process of tool wear correctly and the LM algorithm is more accurate in comparison with the gradient descent methods. Therefore, it casts new light on practical application of neural network in the field of on line tool condition monitoring.

Similar content being viewed by others

References

Bhattacharyya P., Sengupta D., Mukhopadhyay S. (2007) Cutting force-based real-time estimation of tool wear in face milling using a combination of signal processing techniques. Mechanical Systems and Signal Processing 21(6): 2665–2683. doi:10.1016/j.ymssp.2007.01.004

Brezak D., Udiljak T., Majetic D., Novakovic B., Kasac J. (2004) Tool wear monitoring using radial basis function neural network. Neural Networks 3: 1859–1862. doi:10.1109/IJCNN.2004.1380892

Clifford, G., Tarassenko, L., & Townsend, N. (2000). Fusing conventional ECG QRS detection algorithms with an auto-associative neural network for the detection of ectopic beats. In Proceedings of 5th International Conference on Signal Processing, Beijing, China, August 21–25, 2000, vol. 3, pp. 1623–1628. doi:10.1109/ICOSP.2000.893412.

Dev, A., Kröse, B. J. A., & Groen, F. C. A. (1995). Recovering patch parameters from the optic flow with auto associative neural networks. In Proceedings of the 1995 International Conference on Intelligent Autonomous Systems, Karlsruhe, Germany, March 27–30, 1995, pp. 213–216.

Dimla D. E. (1999) Application of perceptron neural networks to tool-state classification in a metal-turning operation. Engineering Applications of Artificial Intelligence 12(4): 471–477. doi:10.1016/S0952-1976(99)00015-9

Dimla D. E., Lister P. M. (2000) On-line metal cutting tool condition monitoring. II: Tool-state classification using multi-layer perceptron neural networks. International Journal of Machine Tools and Manufacture 40(5): 769–781. doi:10.1016/S0890-6955(99)00085-1

Hagan M. T., Menhaj M. B. (1994) Training feedforward networks with the Marquardt algorithm. IEEE Transactions on Neural Networks 5(6): 989–993. doi:10.1109/72.329697

Hong G. S., Rahman M., Zhou Q. (1996) Using neural network for tool condition monitoring based on wavelet decomposition. International Journal of Machine Tools and Manufacture 36(5): 551–566. doi:10.1016/0890-6955(95)00067-4

Huang S. N., Tan K. K., Wong Y. S., Silva C. W., Goh H. L., Tan W. W. (2007) Tool wear detection and fault diagnosis based on cutting force monitoring. International Journal of Machine Tools and Manufacture 47(3–4): 444–451. doi:10.1016/j.ijmachtools.2006.06.011

Hwang, B., & Cho, S. (1999). Characteristics of auto associative MLP as a novelty detector. In Proceedings of International Joint Conference on Neural Networks, Washington, DC, USA, July 10–16, 1999, vol. 5, pp. 3086–3091. doi:10.1109/IJCNN.1999.836051.

Jemielniak K., Kwiatkowski L., Wrzosek P. (1998) Diagnosis of tool wear based on cutting forces and acoustic emission measures as inputs to a neural network. Journal of Intelligent Manufacturing 9: 447–455. doi:10.1023/A:1008896516869

Jung, C., Ban S. W, Jeong, S., & Lee, M. (2010). Input and output mapping sensitive auto-associative multilayer perceptron for computer interface system based on image processing of laser pointer spot. In Proceedings of the 17th international conference on Neural information processing: Models and applications-Part II, Sydney, Australia, November 21–25, pp. 185–192. doi:10.1007/978-3-642-17534-3_23.

Kaya B., Oysu C., Huseyin M.E. (2011) Force-torque based on-line tool wear estimation system for CNC milling of Inconel 718 using neural networks. Advances in Engineering Software 42: 76–84. doi:10.1016/j.advengsoft.2010.12.002

Kermani B. G., Schiffman S. S., Nagle H. T. (2005) Performance of the Levenberg–Marquardt neural network training method in electronic nose applications. Sensors and Actuators B: Chemical 110(1): 13–22. doi:10.1016/j.snb.2005.01.008

Kramer M. A. (1991) Nonlinear principal component analysis using auto associative neural networks. AIChE Journal 37(2): 233–243. doi:10.1002/aic.690370209

Kuo R. J. (2000) Multi-sensor integration for on-line tool wear estimation through artificial neural networks and fuzzy neural network. Engineering Applications of Artificial Intelligence 13(3): 249–261. doi:10.1016/S0952-1976(00)00008-7

Mirzaee H. (2009) Long-term prediction of chaotic time series with multi-step prediction horizons by a neural network with Levenberg–Marquardt learning algorithm. Chaos, Solitons and Fractals 41(4): 1975–1979. doi:10.1016/j.chaos.2008.08.016

Najafi, M. (2003). Use of autoassociative neural network for sensor diagnostics. PhD thesis. Texas A&M University.

Polini, W., & Turchetta, S. (2009). Monitoring of diamond mill wear in time domain during stone cutting using cutting force measurements. Advances in Mechanical Engineering, pp. 1–9. doi:10.1155/2009/353504.

Purushothaman S. (2010) Tool wear monitoring using artificial neural network based on extended Kalman filter weight updation with transformed input patterns. Journal of Intelligent Manufacturing 21: 717–730. doi:10.1007/s10845-009-0249-y

Sanz J., Perera R., Huerta C. (2007) Fault diagnosis of rotating machinery based on auto-associative neural networks and wavelet transforms. Journal of Sound and Vibration 302(4–5): 981–999. doi:10.1016/j.jsv.2007.01.006

Srinivasa Pai P., Nagabhushana T. N., Ramakrishna Rao P. K. (2002) Flank wear estimation in face milling based on radial basis function neural networks. International Journal of Advanced Manufacturing Technology 20(4): 241–247. doi:10.1007/s001700200148

Venkatesh K., Zhou M., Caudill R. J. (1997) Design of artificial neural networks for tool wear monitoring. Journal of Intelligent Manufacturing 8(3): 215–226. doi:10.1023/A:1018573224739

Wilkinson P., Reuben R. L. (1999) Tool wear prediction from acoustic emission and surface characteristics via an artificial neural network. Mechanical Systems and Signal Processing 13(6): 955–966. doi:10.1006/mssp.1999.1231

Xu, C. W., Fan, X., & Luo, W. C. (2009). Research of tool wear based on radical basic function network. In Proceedings of the International MultiConference of Engineers and Computer Scientists, Hong Kong, China, March 18–20, 2009, vol. 1, pp. 133–138.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, G., Cui, Y. On line tool wear monitoring based on auto associative neural network. J Intell Manuf 24, 1085–1094 (2013). https://doi.org/10.1007/s10845-012-0636-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-012-0636-7