Abstract

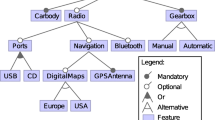

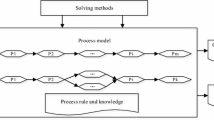

In this paper, the product configuration problems that are characterized by cardinality-based configuration rules are dealt with. Novel configuration rules including FI and EI rules are presented to clarify the semantics of inclusion rules when cardinalities and hierarchies of products are encountered. Then, a configuration graph is proposed to visualize structural rules and configuration rules in product configuration problem. An encoding approach is elaborated to transform the configuration graph as a CSP (Constraint Satisfaction Problem). As a consequence, existing CSP solver, i.e. JCL (Java Constraint Library), is employed to implement the configuration system for product configuration problem with cardinality-related configuration rules. A case study of a bus configuration is used throughout this paper to illustrate the effectiveness of the presented approach.

Similar content being viewed by others

References

Aldanondo M., Hamou K. H., Moynarda G., Lamothe J. (2003) Mass customization and configuration: Requirement analysis and constraint based modeling propositions. Integrated Computer-Aided Engineering 10(2): 177–189

Aldanondo M., Vareilles E. (2008) Configuration for mass customization: How to extend product configuration towards requirements and process configuration. Journal of Intelligent Manufacturing 19: 521–535

Anselma, L., & Magro, D. (2003). Dynamic problem decomposition in configuration. In Proceedings of configuration workshop, 18th international joint conference on artificial intelligence (IJCAI-03) (pp. 21–26). Mexico: Acapulco.

Barker V. E., O’Connor D. E., Bachant J., Soloway E. (1989) Expert systems for configuration at digital: XCON and beyond. Communications of the ACM 32(3): 298–318

Barták R., Salido M. A, Rossi F. (2010) Constraint satisfaction techniques in planning and scheduling. Journal of Intelligent Manufacturing 21(1): 5–15

Czarnecki, K., & Kim, C. H. P. (2005). Cardinality-based feature modeling and constraints: a progress report. In Proceedings of international workshop on software factories. California: San Diego.

Felfernig A., Friedrich G., Jannach D. (2000) UML as domain specific language for the construction of knowledge-based configuration systems. International Journal of Software Engineering and knowledge Engineering 10(4): 449–469

Felfernig A., Friedrich G., Jannach D. (2002) Conceptual modeling for configuration of mass-customizable products. Artificial Intelligence in Engineering 15(2): 165–176

Fohn S. M., Liau J. S., Greef A. R., Young R. E., O’Grady P. J. (1995) Configuring computer systems through constraint-based modeling and interactive constraint satisfaction. Computers in Industry 27(1): 3–21

Hong G., Hu L., Xue D., Tu Y. L., Xiong Y. L. (2008) Identification of the optimal product configuration and parameters based on individual customer requirements on performance and costs in one-of-a-kind production. International Journal of Production Research 46(12): 3297–3326

Jiao J., Tseng M. M., Duffy V. G., Lin F. (1998) Product family modeling for mass customization. Computers and Industrial Engineering 35(3-4): 495–498

Jiao J. X., Simpson T. W., Siddique Z. (2007a) Product family design and platform-based product development: A state-of-the-are review. Journal of Intelligent Manufacturing 18: 5–29

Jiao J. X., Zhang Y., Wang Y. (2007b) A generic genetic algorithm for product family design. Journal of Intelligent Manufacturing 18(2): 233–247

Mackworth A. K. (1977) Consistency in networks of relations. Artificial Intelligence 8(1): 99–118

Marriott K., Stuckey P. J. (1999) Programming with constraints: an introduction. MIT press, Cambridge

Mittal, S., & Frayman, F. (1989). Towards a generic model of configuration tasks. In: Proceedings of the 11th international joint conference on artificial intelligence. San Mateo, CA.

Ong S. K., Lin Q., Nee A. Y. C. (2006) Web-based configuration design system for product customization. International Journal of Production Research 44(2): 351–382

Pine B. J. (1993) Mass customization: The new frontier in business competition. Harvard School Business Press, Boston, Massachusetts

Sabin D., Weigel R. (1998) Product configuration frameworks—a survey. IEEE Intelligent System 13(4): 42–49

Shao X. Y., Wang Z. H., Li P. G., Feng C. X. J. (2006) Integrating data mining and rough set for customer group-based discovery of product configuration rules. International Journal of Production Research 44(14): 2789–2811

Soininen, T., & Gelle, E. (1999). Dynamic constraint satisfaction in configuration. In: Proceedings of AAAI workshop on configuration(pp. 95–106).

Song Z., Kusiak A. (2009) Optimizing product configurations with a data-mining approach. International Journal of Production Research 47(7): 1733–1751

Stallman R. M., Sussman G. J. (1977) Forward reasoning and dependency-directed backtracking in a system for computer-aided circuit analysis. Artificial Intelligence 9(2): 135–196

Stumptner M., Friedrich G. E., HaselBock A. (1998) A generative constraint based configuration of large technical systems. Artificial Intelligence for Engineering, Design, Analysis and Manufacturing 12(4): 302–320

Tseng H. E., Chang C. C., Chang S. H. (2005) Applying case-based reasoning for product configuration in mass customization environments. Expert Systems with Applications 29(4): 913–925

Tsang E. (1993) Foundations of constraint satisfaction. Academic Press, London

Viappiani, P. (2004). Java Constraints Library (JCL). http://liawww.epfl.ch/Research/jcl.html/.

Xie H., Henderson P., Kernahan M. (2005) Modelling and solving engineering product configuration problems by constraint satisfaction. International Journal of Production Research 43(20): 4455–4469

Yeh J. Y., Wu T. S. (2005) Solutions for product configuration management: An empirical study. Artificial Intelligence for Engineering Design, Analysis and Manufacturing (AIEDM) 19(1): 39–47

Yvars P. A. (2009) A CSP approach for the network of product lifecycle constraints consistency in a collaborative design context. Engineering Applications of Artificial Intelligence 22(6): 961–970

Zhu B., Wang Z., Yang H., Mo R., Zhao Y. (2008) Applying fuzzy multiple attributes decision making for product configuration. Journal of Intelligent Manufacturing 19(5): 591–598

Zhang J. S., Wang Q. F., Wan L., Zhong Y. F. (2005) Configuration-oriented product modeling and knowledge management for made-to-order manufacturing enterprises. The International Journal of Advanced Manufacturing Technology 25: 41–52

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, D., Dong, M. Applying constraint satisfaction approach to solve product configuration problems with cardinality-based configuration rules. J Intell Manuf 24, 99–111 (2013). https://doi.org/10.1007/s10845-011-0544-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-011-0544-2