Abstract

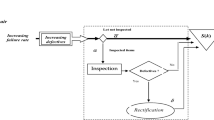

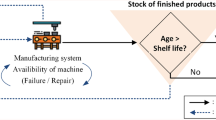

In this paper, we develop a joint quality control and preventive maintenance policy for a production system producing conforming and nonconforming units. The considered system consists of one machine which must supply another production line operating on a just-in-time basis. Each lot produced by the machine is subject to a quality control. According to the proportion l of nonconforming units observed and compared to a threshold value l m , one decides to undertake or not maintenance actions on the system. In order to palliate perturbations caused by the stopping of the machine for preventive and corrective maintenance actions of random durations, a buffer stock h is built up to ensure the continuous supply of the subsequent production line. The proposed strategy is modelled using simulation and experimental design. This approach allows to generate a second order response surface allowing to easily determine the optimal rate, \({l_{m}^*}\), of nonconforming units on the basis of which preventive maintenance actions should be performed, and the optimal size, h*, of the buffer stock to be built. These values minimize the total cost per time unit which includes the costs related to maintenance, quality and inventory.

Similar content being viewed by others

References

Ben Daya M. (1999) Integrated production maintenance and quality model for imperfect processes. IIE Transactions 31: 491–501

Ben Daya M. (2002) The economic production lot-sizing problem with imperfect production processes and imperfect maintenance. International Journal of Production Economics 76: 257–264

Boukas E.K., Haurie A. (1990) Manufacturing flow control and preventive maintenance: A stochastic control approach. IEEE Transactions on Automatic Control 35: 1024–1031

Chelbi A., Aït-Kadi D. (2004) Analysis of a production/inventory system with randomly failing production unit submitted to regular preventive maintenance. European Journal of Operational Research 156(3): 712–718

Chelbi A., Rezg N. (2006) Analysis of a production/inventory system with randomly failing production unit subjected to a minimum required availability level. International Journal of Production Economics 99: 131–143

Gharbi, A., & Kenne, J. P. (2000). Production and corrective maintenance planning of FMS through simulation optimisation. 4th International Conference on Engineering Design and Automation, Orlando, Florida, USA.

Groenevelt H., Pintelon L., Seidmann A. (1992a) Production lot sizing with machine breakdowns. Management Science 38(1): 104–123

Groenevelt H., Pintelon L., Seidmann A. (1992b) Production batching with machine breakdowns and safety stocks. Operations Research 40(5): 959–971

Kenne J.P., Gharbi A. (2001) A simulation optimization approach in production planning of failure prone manufacturing systems. Journal of Intelligent Manufacturing 12(5): 421–431

Meller R.D., Kim D.S. (1996) The impact of preventive maintenance on system cost and buffer size. European Journal of Operational Research 95: 577–591

Rezg N., Chelbi A., Xiaolan X. (2005) Modeling and optimizing a joint buffer inventory and preventive maintenance strategy for a randomly failing production unit: Analytical and simulation approaches. International Journal of Computer Integrated Manufacturing 18(2–3): 225–235 ISSN 0951-192X

Sado, G., & Sado, M.-C. (1991). Les plans d’expériences (de l’expérimentation à l’assurance qualité). AFNOR technique, ISBN 2-12-450311-1.

Salameh, M. K., Ghattas, R. E., & Maddah, B. S. (1999). Optimal just-in-time buffer inventory for regular preventive maintenance. International Conference on Industrial Engineering and Production Management, Vol. 1, pp. 194–200.

Van der Dayn Schouen F.A., Vanneste S.G. (1995) Maintenance optimization of a production system with buffer capacity. European Journal of Operational Research 82(2): 323–338

Wang P., Gray W.J., Scott M. (1999) Quality-related measures of unreliable machines with preventive maintenance. Computers & Operations Research 10(23): 981–996

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Radhoui, M., Rezg, N. & Chelbi, A. Joint quality control and preventive maintenance strategy for imperfect production processes. J Intell Manuf 21, 205–212 (2010). https://doi.org/10.1007/s10845-008-0198-x

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-008-0198-x