Abstract

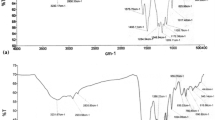

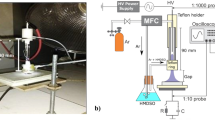

This work investigates a new organic coating for corrosion protection. This coating is a Poly(n-butyl acrylate-b-trifluoroethyl methacrylate) diblock copolymer elaborated by Controlled Radical Polymerization and then deposited on steel. Several parameters were taken into account to evaluate their influence on corrosion protection properties: the PBA molar mass, the solvent type (THF or Dichloromethane), the thickness of coatings and the nature of the nanostructuration (lamellae or sphere). The thickness of the films was measured between 45 and 265 μm by optical microscopy and by gravimetric difference measurements. Atomic Force Microscopy (AFM) observations show a homogeneous surface of the coating with a nanostructured lamellar structure. The electrochemical behaviour was studied by Electrochemical Impedance Spectroscopy (EIS) in a sodium sulphate solution. The better corrosion resistance was obtained for coating thickness higher than 265 μm. On the other hand, poor results were obtained using a PBA high molar mass and dichloromethane as solvent.

Similar content being viewed by others

References

Determination of coating performance with impedance measurements, TNO Centre for Coatings Research Delft, The Netherlands, (1992).

N.S. Sangaj and V.C. Malshe, Progress in Organic Coatings, 50, 28 (2004).

C.M. Hansen, Progress in Organic Coatings, 51, 55 (2004).

C. K. Schoff, Progress in Organic Coatings, (2004).

L.H. Sperling, Introduction to Physical Polymer Science, 2nd Edition, J. Wiley & Sons, (1992), Chapter 4.

I.W. Hamley, The Physics of Block Copolymers, ed. Oxford Science Publications, (1998), Chapter 2.

D. Bertin, M. Destarac, B. Boutevin, Polymers and Surfaces, 47 (1998).

P.L. Bonora, F. Deflorian, and L. Fedrizzi, Electrochimica Acta, 41, 1073 (1996).

F. Deflorian, L. Fedrizzi, S. Rossi, and P.L. Bonora, Electrochimica Acta, 44, 4243 (1999).

Z. Kloek, Progress in Organic Coatings, 30, 287 (1997).

F. Deflorian, L. Fedrizzi, S. Rossi, F. Buratti, and P.L. Bonora, Progress in Organic Coatings, 39, 9 (2000).

T. To, H. Wang, A.B. Djurisic, M.H. Xie, W.K. Chan, Z. Xie, C. Wu, S.Y. Tong, Thin Solid Films, 467, 59 (2004).

D.M. Brasher and A.H. Kingsbury, J. Appl. Chem., 4, 62 (1954).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roche, V., Vacandio, F., Bertin, D. et al. Corrosion performance of lamellae nanostructured fluorinated organic coating applied on steel. J Electroceram 16, 41–47 (2006). https://doi.org/10.1007/s10832-006-2366-8

Received:

Revised:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10832-006-2366-8