Abstract

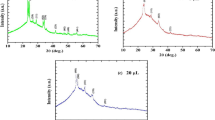

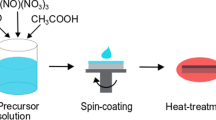

Aluminum (Al) coatings, which are found to be dendrites, have been deposited on uranium (U) substrate in ionic liquid via galvanic displacement. Interestingly, a dense Al nano-layer has formed between the Al dendrites and the U substrate. In this work, the growth mechanism of the Al coating has been investigated by ultraviolet–visible spectroscopy, scanning electron microscopy, grazing incidence X-ray diffraction, and electrochemical measurements: the galvanic reaction sees the oxidation of U from the substrate while Al2Cl7− are reduced on its surface, driven by the electrochemical potential difference between Al and U. Furthermore, we have found that the Al nano-layer passivates the uranium surface, which is proved to be the rate limiting step in the galvanic deposition process; the observation of the interface morphology evolution process indicates that this Al nano-layer grows in a three-dimensional mode. This work demonstrates a convenient approach to deposit dense Al nano-layer on U, without any external power source.

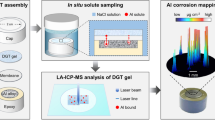

Graphical Abstract

Similar content being viewed by others

References

Lee DJ, Lee HS (2006) Microelectron Reliab 46:1194

Liu FM, Green. M (2004) J Mater Chem 14:1526

Neves HP, Kudrle TD, Chen JM, Adams SG, Maharbiz M, Lopatin S, MacDonald NC (1998) MRS Proc 546:139

Yeh JLA, Jiang H, Neves HP, Tien NC (2008) J Microelectromech S 9:281

Shacham-Diamand Y, Sverdlov Y (2000) Microelectron Eng 50:525

Abbott AP, Frisch G, Hartley J, Karim WO, Ryder KS (2015) Prog Nat Sci Mater 25:595

Abbott AP, Frisch G, Ryder KS (2013) Annu Rev Mater Res 43:335

Wang YC, Lin JY, Han Wang C, Huang PL, Lee SL, Chang JK (2014) RSC Adv 4:35298

Falola BD (2015) I. I. Suni. Curr. Opin. Solid State Mater Sci 19:77

DaRosa CP, Iglesia E, Maboudian. R (2008) J Electrochem Soc 155:244

DaRosa CP, Maboudian R, Iglesia. E (2008) J Electrochem Soc 155:70

DaRosa CP, Maboudian R, Iglesia E (2009) Electrochim Acta 54:3270

Abbott AP, Nandhra S, Postlethwaite S, Smith EL, Ryde KS (2007) Phys Chem Chem Phys 9:3735

Lahiri A, Borisenko N, Olschewski M, Gustus R, Zahlbach J, Endres F (2015) Angew Chem Int Ed 54:11870

Jiang YD, Ding JJ, Luo LZ, Shi P, Wang XL (2017) Surf Coat Technol 309:980

Egert CM, Scott. DG (1987) J Vac Sci Technol A 5:2724

Wilkes JS, Levisky JA, Wilson RA, Hussey CL (1982) Inorg Chem 21:1263

Jiang YD, Luo LZ, Wang SF, Bing R, Zhang GK, Wang XL (2018) Appl Surf Sci 427:528

Jiang T, Brym MJC, Dubé G, Lasia A, Brisard GM (2006) Surf Coat Technol 201:1

Falola BD, Suni. II (2014) J Electrochem Soc 161:107

Luo YR (2007) Comprehensive hand book of chemical bond energies. CRC Press, Boca Raton

Johnson AJ, Shreir LL (1965) Corros Sci 5:269

Carraro C, Maboudian R, Magagnin L (2007) Surf Sci Rep 62:499

Landolt D (1987) Electrochim Acta 32:1

Acknowledgements

The authors would like to thank Prof. Ling, Prof. Zhang, Colleague Xiandong Meng and Anyi Yin for technical support. And this work is supported by the National Natural Science Foundation of China (No. 11404295), National Key Scientific Apparatus Development of Special Item of China (No. 2012YQ130125) and the Disipline Development Foundation of China Academy of Engineering and Physics (No. 2015B0301065).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, Y., Fang, L., Luo, L. et al. Deposition mechanism of aluminum on uranium in AlCl3-1-ethyl-3-methylimidazolium chloride ionic liquid by galvanic displacement. J Appl Electrochem 48, 827–834 (2018). https://doi.org/10.1007/s10800-018-1204-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-018-1204-4