Abstract

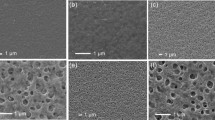

Porous glass (PG) offers the ability to vary pore sizes and modify surfaces, allowing membranes to be tailored for a given electrochemical application. In this contribution, the application of PG in all-vanadium redox-flow batteries (VFB) and the effect of surface modification with sulfonic acid groups were investigated, and the results were compared with those from well-known polymeric membranes. The performance of native and surface-modified PG membranes with pore sizes ranging from 2 to 20 nm and thicknesses of 300 and 500 µm was investigated by examining their self-discharge behavior, polarization curves and area resistance. A maximum power density of 77 mW cm−2 at a current density of 110 mA cm−2 was observed with the modified membrane 505FDS, and this density is approximately half the power density achieved with Nafion™ 117. The results can be related to the small vanadium crossover, high conductivity and chemical stability. Therefore, the great potential of PG membranes as separators in VFBs was shown.

Graphical Abstract

Similar content being viewed by others

References

Fabjan C, Garche J, Harrer B, Jörissen L, Kolbeck C, Philippi F, Thomazic G, Wagner F (2001) The vanadium redox-battery: an efficient storage unit for photovoltaic systems. Electrochim Acta 47:825–831

Jörissen L, Garche J, Fabjan C, Thomazic G (2004) Possible use of vanadium redox-flow batteries for energy storage in small grids and stand-alone photovoltaic systems. J Power Sources 127:98–104

Chae S, Luo T, Moon GH, Ogieglo W, Kang YS, Wessling M (2016) Ultra-high proton/vanadium selectivity for hydrophobic polymer membranes with intrinsic nanopores for redox flow battery. Adv Energy Mater 6:1600517

Park M, Ryu J, Wang W, Cho J (2016) Material design and engineering of next-generation flow-battery technologies, Nat Rev Mater. https://doi.org/10.1038/natrevmats.2016.80

Leung P, Shah AA, Sanz L, Flox C, Morante JR, Xu Q, Mohamed MR, Ponce C, de Leon FC, Walsh (2017) Recent developments in organic redox flow batteries: a critical review. J Power Sources 360:243–283

Leung P, Li X, Ponce de León C, Berlouis L, Low CTJ, Walsh FC (2012) Progress in redox flow batteries, remaining challenges and their applications in energy storage. R Soc Chem Adv 2:10125–10156

Ponce de León C, Frías-Ferrer A, González-García J, Szánto DA, Walsh FC (2006) Redox flow cells for energy conversion. J Power Sources 160:716–732

Arenas-Martínez LF, Ponce de León C, Walsh FC (2017) Engineering aspects of the design, construction and performance of modular redox flow batteries for energy storage. J Energy Storage 11:119–153

Kear G, Sha AA, Walsh FC (2011) Development of the all-vanadium redox flow battery or energy storage: a review of technological, financial and policy aspects. Int J Energy Res 36:1105–1120

Minke C, Turek T (2018) Materials, system designs and modelling approaches in techno-economic assessment of all-vanadium redox flow batteries—a review. J Power Sources 376:66–81

Skyllas-Kazacos M, Rychcik M, Robins RG, Fane AG, Green MA (1986) New all-vanadium redox flow cell. J Electrochem Soc. Accelerated Brief Communication,

Roznyatovskaya N, Herr T, Küttinger M, Fühl M, Noack J, Pinkwart K, Tübke J (2016) Towards an all-vanadium redox-flow battery electrolyte: electrooxidation of V(III) in V(IV)/V(III) redox couple. J Power Sources 302:79–83

Parasuraman A, Lim TM, Menictas C, Skyllas-Kazacos M (2013) Review of material research and development for vanadium redox flow battery applications. Electrochim Acta 101:27–40

Xi J, Wu Z, Qiu X, Chen L (2007) Nafion/SiO2 hybrid membrane for vanadium redox flow battery. J Power Sources 166:531–536

Zhang H, Zhang H, Li X, Mai Z, Wei W (2012) Silica modified nanofiltration membranes with improved selectivity for redox flow battery application. Energy Environ Sci 5:6299–6303

Li Y, Tay ZY, Li SFY (2017) Highly selective sulfonated poly(ether ether ketone)/titanium oxide composite membranes for vanadium redox flow batteries. J Membr Sci 539:197–205

Slade SM, Campbell SA, Ralph TR, Walsh FC (2002) Ionic conductivity of an extruded Nafion 1100 EW series of membranes. J Electrochem Soc 149(12):A1556–A1564

Slade SM, Smith JR, Campbell SA, Ralph TR, de León C, Walsh FC (2010) Characterisation of a re-cast composite Nafion™ 1100 series of proton exchange membranes incorporating inert inorganic oxide particles. Electrochimica Acta 55:6818–6829

Fang B, Wei Y, Arai T, Iwasa S, Kumagai M (2003) Development of a novel redox flow battery for electricity storage system. J Appl Electrochem 33:197–203

Enke D, Janowski F, Schwieger W (2003) Porous glasses in the 21st century—a short review. Microporous Mesoporous Mater 60(1–3):19–30

Janowski F, Enke D (2002) In: Schüth F, Sing K.S.W., Weitkamp J (Hrsg) Handbook of porous solids, band 3.Wiley-VCH, Weinheim, p 1432

Kikukawa T, Kuraoka K, Kawabe K, Yasuda K, Hirao K, Yazawa T (2004) Preparation of an organic-inorganic hybrid ionic conductive material with thermal and chemical stability. J Am Ceram Soc 87(3):504–506

Mögelin H, Yao G, Zhong H, dos Santos AR, Barascu A, Meyer R, Krenkel S, Wassersleben S, Hickmann T, Enke D, Turek T, Kunz U (2018) Porous Glass Membranes for vanadium redox-flow-battery application—effect of pore size on the performance. J Power Sources 377:18–25

Enke D, Otto K, Janowski F, Heyer W, Schwieger W, Gille W (2001) Two-phase porous silica: mesopores inside controlled pore glasses. J Mater Sci 36(9):2349–2357

Kreisberg VA, Antropova TV (2014) Changing the relation between micro- and mesoporosity in porous glasses: the effect of different factors. Microporous Mesoporous Mater 190:128–138

Brunauer S, Emmett PH, Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60(2):309–319

Ravikovitch PI, Haller GL, Neimark AV (1998) Density functional theory model for calculating pore size distributions: pore structure of nanoporous catalysts. Adv Colloid Interface Sci 76–77:203–226

Ravikovitch PI, Neimark AV (2001) Characterization of micro- and mesoporosity in SBA-15 materials from adsorption data by the NLDFT method. J Phys Chem B 105:6817–6823

Winardi S, Raghu SC, Oo MO, Yan Q, Wai N, Lim TM (2014) Sulfonated poly (ether ether ketone)-based proton exchange membranes for vanadium redox battery applications. J Membr Sci 450:313–322

Seo SJ, Kim BC, Sung KW, Shim J, Jeon JD, Shin KH, Shin SH, Yun SH, Lee JY, Moon SH (2013) Electrochemical properties of pore-filled anion exchange membranes and their ionic transport phenomena for vanadium redox flow battery applications. J Membr Sci 428:17–23

Li X, Zhang H, Mai Z, Zhang H, Vankelecom I (2011) Ion exchange membranes for vanadium redox flow battery (VRB) applications. Energy Environ Sci 4:1147

Arenas LF, Walsh FC, Ponce de Léon C (2015) 3D-printing of redox flow batteries for energy storage: a rapid prototype laboratory cell. J Solid State Sci Technol 4:3080–3085

Becker M, Bredemeyer N, Tenhumberg N, Turek T (2016) Polarization curve measurements combined with potential probe sensing for determining current density distribution in vanadium redox-flow batteries. J Power Sources 307:826–833

Mohamed MR, Ahmad H, Abu Seman MN, Razali S, Najib MS (2013) Electrical circuit model of a vanadium redox flow battery using extended Kalman filter. J Power Sources 239:284–293

Dai W, Yu L, Li Z, Yan J, Liu L, Xi J, Qiu X (2014) Sulfonated Poly(ether ether ketone)/graphene composite membrane for vanadium redox flow battery. Electrochim Acta 132:200–207

Qiu J, Li M, Ni J, Zhai M, Peng J, Xu L, Zhou H, Li J, Wei G (2007) Preparation of ETFE-based anion exchange membrane to reduce permeability of vanadium ions in vanadium redox battery. J Membr Sci 297:174–180

Acknowledgements

The authors would like to thank the Energy Research Center of Lower Saxony (Energie-Forschungszentrum Niedersachsen) and are grateful for the funding provided by the Deutsche Forschungsgemeinschaft (DFG) [Project Numbers KU 853/15-1 and EN 942/6-1]. Additionally, the authors would like to thank Eisenhuth GmbH & Co. KG for providing bipolar plates and gaskets and their very constructive cooperation.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mögelin, H., Barascu, A., Krenkel, S. et al. Effect of the pore size and surface modification of porous glass membranes on vanadium redox-flow battery performance. J Appl Electrochem 48, 651–662 (2018). https://doi.org/10.1007/s10800-018-1201-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-018-1201-7