Abstract

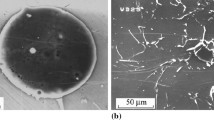

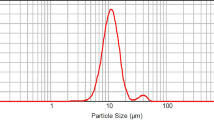

Plasma electrolytic oxidation coating is obtained on AA6061 alloy using positive uni-polar pulsed DC in a sodium silicate-based electrolyte. The effect of process parameters such as solution concentration, process time, average current density, pulse frequency and positive on-time is investigated systematically and the corresponding voltage–time response is correlated with the coating growth rate. Surface morphology of the coatings is studied using scanning electron microscopy and the elemental distribution on the coating is investigated using energy dispersive X-ray spectroscopy. The concentration of sodium silicate in the solution is found to play a key role in determining the morphology and composition of the coating. X-ray diffraction studies indicate a transition from crystalline to amorphous nature of the coating with increase in silicate content of the electrolyte. Effect of pulse frequency on the voltage–time response and the corresponding coating growth rate is highly dependent on the solution concentration.

Graphical Abstract

Similar content being viewed by others

References

Yerokhin AL, Nie X, Leyland A, Matthews A, Dowey SJ (1999) Plasma electrolysis for surface engineering. Surf Coat Technol 122:73–93

Walsh FC, Low CTJ, Wood RJK, Stevens KT, Archer J, Poeton AR, Ryder A (2009) Plasma electrolytic oxidation (PEO) for production of anodised coatings on lightweight metal (Al, Mg, Ti) alloys. Trans Inst Met Finish 87:122–135

Gupta P, Tenhundfeld G, Daigle EO, Ryabkov D (2007) Electrolytic plasma technology: science and engineering—an overview. Surf Coat Technol 201:8746–8760

Zhang Y, Fan W, Du HQ, Zhao YW (2017) Plasma electrolytic oxidation coatings for aluminum alloys. Mater Perform 56(9):38–41

Rizwan M, Alias R, Zaidi UZ, Mahmoodian R, Hamdi M (2018) Surface modification of valve metals using plasma electrolytic oxidation for antibacterial applications: a review. J Biomed Mater Res A 106(2):590–605

Matykina E, Arrabal R, Mohedano M, Mingo B, Gonzalez J, Pardo A, Merino MC (2017) Recent advances in energy efficient PEO processing of aluminium alloys. Trans Nonferrous Met Soc China 27(7):1439–1454

Tian J, Luo Z, Qi S, Sun X (2002) Structure and antiwear behavior of micro-arc oxidized coatings on aluminum alloy. Surf Coat Technol 154:1–7

Dearnley PA, Gummersbach J, Weiss H, Ogwu AA, Davies TJ (1999) The sliding wear resistance and frictional characteristics of surface modified aluminium alloys under extreme pressure. Wear 225–229:127–134

Voevodin AA, Yerokhin AL, Lyubimov VV, Donley MS, Zabinski JS (1996) Characterization of wear protective Al-Si-0 coatings formed on Al-based alloys by micro-arc discharge treatment. Surf Coat Technol 86–87:516–521

Wasekar NP, Jyothirmayi A, Krishna LR, Sundararajan G (2008) Effect of micro arc oxidation coatings on corrosion resistance of 6061-Al alloy. J Mater Eng Perform 17(5):708–713

Bajat JB, Vasili R, Stojadinovi S, Miškovi-Stankovi V (2013) Corrosion stability of oxide coatings formed by plasma electrolytic oxidation of aluminum: optimization of process time. Corrosion 69:693–702

Liu YJ, Xu JY, Lin W, Gao C, Zhang JC, Chen XH (2013) Effects of different electrolyte systems on the formation of micro-arc oxidation ceramic coatings of 6061 aluminum alloy. Rev Adv Mater Sci 33:126–130

Wang K, Koo B-H, Lee C-G, Kim Y-J, Lee S-H, Byon E (2009) Effects of electrolytes variation on formation of oxide layers of 6061 Al alloys by plasma electrolytic oxidation. Trans Nonferrous Met Soc China 19:866–870

Yerokhin AL, Voevodin AA, Lyubimov VV, Zabinski J, Donley M (1998) Plasma electrolytic fabrication of oxide ceramic surface layers for tribotechnical purposes on aluminium alloys. Surf Coat Technol 110:140–146

Gnedenkov SV, Khrisanfova OA, Zavidnaya AG, Sinebrukhov SL, Kovryanov AN, Scorobogatova TM, Gordienko PS (2000) Production of hard and heat-resistant coatings on aluminium using a plasma micro-discharge. Surf Coat Technol 123:24–28

Yerokhin AL, Nie X, Leyland A, Matthews A (2000) Characterisation of oxide films produced by plasma electrolytic oxidation of a Ti6Al4V alloy. Surf Coat Technol 130:195–206

Li H, Song R, Ji Z (2013) Effects of nano-additive TiO2 on performance of micro-arc oxidation coatings formed on 6063 aluminum alloy. Trans Nonferrous Met Soc China 23:406–411

Arrabal R, Matykina E, Viejo F, Skeldon P, Thompson GE, Merino MC (2008) AC plasma electrolytic oxidation of magnesium with zirconia nanoparticles. Appl Surf Sci 254:6937–6942

Stojadinovic S, Vasilic R, Belca I, Petkovic M, Kasalica B, Nedic Z, Zekovic Lj (2010) Characterization of the plasma electrolytic oxidation of aluminium in sodium tungstate. Corros Sci 52:3258–3265

Lukiyanchuk IV, Rudnev VS (2007) Tungsten oxide films on aluminum and titanium. Inorg Mater 43(3):264–267

Rudnev VS, Morozova VP, Lukiyanchuk IV, Adigamova MV, Tkachenko IA, Ustinov AYu, Kharitonskii PV, Frolov AM (2013) Oxide layers with ferro- and ferrimagnetic characteristics formed on aluminum via plasma electrolytic oxidation. Russ J Phys Chem A 87(6):1052–1056

Snizhko LO, Yerokhin AL, Pilkington A, Gurevina NL, Misnyankin DO, Leyland A, Matthews A (2004) Anodic processes in plasma electrolytic oxidation of aluminium in alkaline solutions. Electrochim Acta 49:2085–2095

Guan Y, Yuan X (2006) Correlation between discharging property and coatings microstructure during plasma electrolytic oxidation. Trans Nonferrous Met Soc China 16:1097–1102

Dehnavi V, Luan BL, Liu XY, Shoesmith DW, Rohani S (2015) Correlation between plasma electrolytic oxidation treatment stages and coating microstructure on aluminum under unipolar pulsed DC mode. Surf Coat Technol 269:91–99

Peters M, Leyens C (2009) Aerospace and space materials, materials science and engineering—vol. III. EOLSS Publications

Wernick S, Pinner R, Sheasby PG (1987) The surface treatment and finishing of aluminium and its alloys—vol 1, 5th edn. ASM International

Venugopal A, Srinath J, Krishna LR, Narayanan PR, Sharma SC, Venkitakrishnan PV (2016) Corrosion and nanomechanical behaviors of plasma electrolytic oxidation coated AA7020-T6 aluminum alloy. Mater Sci Eng A 660:39–46

Zhang Y, Fan W, Du HQ, Zhao YW (2018) Formation of corrosion-resistant MAO-treated aluminum alloy. Mater Perform 57(2):36–39

Ma D, Lu C, Fang Z, Yan W, Wei L, Ni Y, Xu Z (2016) Preparation of high absorbance and high emittance coatings on 6061 aluminum alloy with a pre-deposition method by plasma electrolytic oxidation. Appl Surf Sci 389:874–881

Dehnavi V, Surface modification of aluminum alloys by plasma electrolytic oxidation, Thesis from The University of Western Ontario, Canada, September 2014

Hussein RO, Nie X, Northwood DO, Yerokhin A, Matthews A (2010) Spectroscopic study of electrolytic plasma and discharging behaviour during the plasma electrolytic oxidation (PEO) process. J Phys D 43:105203 https://doi.org/10.1088/0022-3727/43/10/105203

Hussein RO, Northwood DO, Nie X (2010) Coating growth behavior during the plasma electrolytic oxidation process. J Vac Sci Technol A 28:766–773

Krishna LR, Purnima AS, Sundararajan G (2006) A comparative study of tribological behavior of microarc oxidation and hard-anodized coatings. Wear 261:1095–1101

Sundararajan G, Krishna LR (2003) Mechanisms underlying the formation of thick alumina coatings through the MAO coating technology. Surf Coat Technol 167:269–277

Jayaraj RK, Malarvizhi S, Balasubramanian V (2017) Optimizing the micro-arc oxidation (MAO) parameters to attain coatings with minimum porosity and maximum hardness on the friction stir welded AA6061 aluminium alloy welds. Def Technol 13(2):111–117

Sobolev A, Kossenko A, Zinigrad M, Borodianskiy K (2017) An investigation of oxide coating synthesized on an aluminum alloy by plasma electrolytic oxidation in molten salt. Appl Sci 7(9):889. https://doi.org/10.3390/app7090889

Acknowledgements

The authors wish to express their sincere gratitude to Prof. S. Sampath, Department of Inorganic and Physical Chemistry, Indian Institute of Science, Bangalore for his valuable guidance and technical assistance in conducting this research work.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Pillai, A.M., Rajendra, A. & Sharma, A.K. Influence of process parameters on growth behaviour and properties of coatings obtained by plasma electrolytic oxidation (PEO) on AA 6061. J Appl Electrochem 48, 543–557 (2018). https://doi.org/10.1007/s10800-018-1186-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-018-1186-2