Abstract

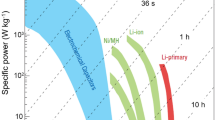

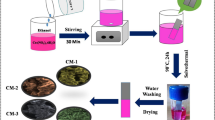

Bacterial cellulose (BC) was used as a raw material to produce freestanding carbon aerogels (CAs). The CAs were further decorated with Ni and MnO2/Ni(OH)2 hybrid via electrodeposition and redox reaction to produce carbon nanofiber networks decorated with electrochemically active metal and metal compounds. The properties of this novel material as supercapacitor electrodes were investigated. The electrochemical performance of the electrodes was examined in 1 M Na2SO4 electrolyte using cyclic voltammetry (CV), cyclic charge–discharge (CCD), and electrochemical impedance spectroscopy (EIS) tests. The results showed that a specific capacitance of 109 F g−1 was achieved at the current density of 1 A g−1. The electrodes could deliver an energy density of 9.4 Wh kg−1 and a power density of 4 KW kg−1 and demonstrated a high cyclability. These results showed great potential of this new material for supercapacitor electrodes. A flexible solid-state supercapacitor prototype was prepared using this material to demonstrate its function as a power source for a LED light. This study provided a new way to use BC as a biobased low-cost material for the fabrication of energy storage devices.

Graphical Abstract

Similar content being viewed by others

References

Haigler CH (1990) Biosynthesis and biodegradation of cellulose. CRC Press, Boca Raton

Klemm D, Heublein B, Fink H-P, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44(22):3358–3393. https://doi.org/10.1002/anie.200460587

Hon DN-S (1994) Cellulose: a random walk along its historical path. Cellulose 1(1):1–25. https://doi.org/10.1007/bf00818796

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494. https://doi.org/10.1007/s10570-010-9405-y

Iguchi M, Yamanaka S, Budhiono A (2000) Bacterial cellulose—a masterpiece of nature’s arts. J Mater Sci 35(2):261–270. https://doi.org/10.1023/a:1004775229149

Zhu H, Luo W, Ciesielski PN, Fang Z, Zhu JY, Henriksson G, Himmel ME, Hu L (2016) Wood-derived materials for green electronics, biological devices, and energy applications. Chem Rev 116(16):9305–9374. https://doi.org/10.1021/acs.chemrev.6b00225

Yamanaka S, Watanabe K, Kitamura N, Iguchi M, Mitsuhashi S, Nishi Y, Uryu M (1989) The structure and mechanical properties of sheets prepared from bacterial cellulose. J Mater Sci 24(9):3141–3145. https://doi.org/10.1007/bf01139032

Ul-Islam M, Khan T, Park JK (2012) Water holding and release properties of bacterial cellulose obtained by in situ and ex situ modification. Carbohyd Polym 88(2):596–603. https://doi.org/10.1016/j.carbpol.2012.01.006

Helenius G, Bäckdahl H, Bodin A, Nannmark U, Gatenholm P, Risberg B (2006) In vivo biocompatibility of bacterial cellulose. J Biomed Mater Res Part A 76A(2):431–438. https://doi.org/10.1002/jbm.a.30570

Liebner F, Haimer E, Wendland M, Neouze M-A, Schlufter K, Miethe P, Heinze T, Potthast A, Rosenau T (2010) Aerogels from unaltered bacterial cellulose: application of scCO2 drying for the preparation of shaped, ultra-lightweight cellulosic aerogels. Macromol Biosci 10(4):349–352. https://doi.org/10.1002/mabi.200900371

Chen L-F, Huang Z-H, Liang H-W, Guan Q-F, Yu S-H (2013) Bacterial-cellulose-derived carbon nanofiber@MnO2 and nitrogen-doped carbon nanofiber electrode materials: an asymmetric supercapacitor with high energy and power density. Adv Mater 25(34):4746–4752. https://doi.org/10.1002/adma.201204949

Conway BE (2013) Electrochemical supercapacitors: scientific fundamentals and technological applications. Springer, New York

Simon P, Gogotsi Y (2008) Materials for electrochemical capacitors. Nat Mater 7(11):845–854

Wang Y, Zhou J, Jiang L, Ulven C, Lubineau G, Liu G, Xiao J (2015) Development of low-cost DDGS-based activated carbons and their applications in environmental remediation and high-performance electrodes for supercapacitors. J Polym Environ 23(4):595–605. https://doi.org/10.1007/s10924-015-0741-8

Zhang LL, Zhao XS (2009) Carbon-based materials as supercapacitor electrodes. Chem Soc Rev 38(9):2520–2531. https://doi.org/10.1039/b813846j

Yu N, Yin H, Zhang W, Liu Y, Tang Z, Zhu M-Q (2016) High-performance fiber-shaped all-solid-state asymmetric supercapacitors based on ultrathin MnO2 nanosheet/carbon fiber cathodes for wearable electronics. Adv Energy Mater. https://doi.org/10.1002/aenm.201501458

Rull-Barrull J, d’Halluin M, Le Grognec E, Felpin F-X (2016) Chemically-modified cellulose paper as smart sensor device for colorimetric and optical detection of hydrogen sulfate in water. Chem Commun 52(12):2525–2528. https://doi.org/10.1039/c5cc09889k

Legnani C, Vilani C, Calil VL, Barud HS, Quirino WG, Achete CA, Ribeiro SJL, Cremona M (2008) Bacterial cellulose membrane as flexible substrate for organic light emitting devices. Thin Solid Films 517(3):1016–1020. https://doi.org/10.1016/j.tsf.2008.06.011

Pushparaj VL, Shaijumon MM, Kumar A, Murugesan S, Ci L, Vajtai R, Linhardt RJ, Nalamasu O, Ajayan PM (2007) Flexible energy storage devices based on nanocomposite paper. Proc Natl Acad Sci 104 (34):13574–13577

Xu J, Zhu L, Bai Z, Liang G, Liu L, Fang D, Xu W (2013) Conductive polypyrrole–bacterial cellulose nanocomposite membranes as flexible supercapacitor electrode. Org Electron 14(12):3331–3338. https://doi.org/10.1016/j.orgel.2013.09.042

Li S, Huang D, Zhang B, Xu X, Wang M, Yang G, Shen Y (2014) Flexible supercapacitors based on bacterial cellulose paper electrodes. Adv Energy Mater. https://doi.org/10.1002/aenm.201301655

Liu Y, Zhou J, Tang J, Tang W (2015) Three-dimensional, chemically bonded polypyrrole/bacterial cellulose/graphene composites for high-performance supercapacitors. Chem Mater 27(20):7034–7041. https://doi.org/10.1021/acs.chemmater.5b03060

Wang F, Kim H-J, Park S, Kee C-D, Kim S-J, Oh I-K (2016) Bendable and flexible supercapacitor based on polypyrrole-coated bacterial cellulose core-shell composite network. Compos Sci Technol 128:33–40. https://doi.org/10.1016/j.compscitech.2016.03.012

Wang X, Kong D, Zhang Y, Wang B, Li X, Qiu T, Song Q, Ning J, Song Y, Zhi L (2016) All-biomaterial supercapacitor derived from bacterial cellulose. Nanoscale 8(17):9146–9150. https://doi.org/10.1039/c6nr01485b

Chen P, Xiao T-Y, Qian Y-H, Li S-S, Yu S-H (2013) A nitrogen-doped graphene/carbon nanotube nanocomposite with synergistically enhanced electrochemical activity. Adv Mater 25(23):3192–3196. https://doi.org/10.1002/adma.201300515

Chen L-F, Huang Z-H, Liang H-W, Yao W-T, Yu Z-Y, Yu S-H (2013) Flexible all-solid-state high-power supercapacitor fabricated with nitrogen-doped carbon nanofiber electrode material derived from bacterial cellulose. Energy Environ Sci 6(11):3331–3338. https://doi.org/10.1039/c3ee42366b

Wang S, Guo X, Liang T, Zhou Y, Luo Z (2012) Mechanism research on cellulose pyrolysis by Py-GC/MS and subsequent density functional theory studies. Bioresour Technol 104:722–728. https://doi.org/10.1016/j.biortech.2011.10.078

Collard F-X, Blin J (2014) A review on pyrolysis of biomass constituents: mechanisms and composition of the products obtained from the conversion of cellulose, hemicelluloses and lignin. Renew Sustain Energy Rev 38:594–608. https://doi.org/10.1016/j.rser.2014.06.013

Neves D, Thunman H, Matos A, Tarelho L, Gómez-Barea A (2011) Characterization and prediction of biomass pyrolysis products. Prog Energy Combust Sci 37(5):611–630. https://doi.org/10.1016/j.pecs.2011.01.001

Gregg S, Jacobs J (1948) An examination of the adsorption theory of Brunauer, Emmett, and Teller, and Brunauer, Deming, Deming and Teller. Trans Faraday Soc 44:574–588

Sun Y, Gao B, Yao Y, Fang J, Zhang M, Zhou Y, Chen H, Yang L (2014) Effects of feedstock type, production method, and pyrolysis temperature on biochar and hydrochar properties. Chem Eng J 240:574–578. https://doi.org/10.1016/j.cej.2013.10.081

Angın D (2013) Effect of pyrolysis temperature and heating rate on biochar obtained from pyrolysis of safflower seed press cake. Bioresour Technol 128:593–597. https://doi.org/10.1016/j.biortech.2012.10.150

Fan Z, Yan J, Wei T, Zhi L, Ning G, Li T, Wei F (2011) Asymmetric supercapacitors based on graphene/MnO2 and activated carbon nanofiber electrodes with high power and energy density. Adv Func Mater 21(12):2366–2375. https://doi.org/10.1002/adfm.201100058

Xu X, Zhou J, Nagaraju DH, Jiang L, Marinov VR, Lubineau G, Alshareef HN, Oh M (2015) Flexible, highly graphitized carbon aerogels based on bacterial cellulose/lignin: catalyst-free synthesis and its application in energy storage devices. Adv Func Mater 25(21):3193–3202

Ren Z, Li J, Ren Y, Wang S, Qiu Y, Yu J (2016) Large-scale synthesis of hybrid metal oxides through metal redox mechanism for high-performance pseudocapacitors. Sci Rep 6:20021

Jin X, Zhou W, Zhang S, Chen GZ (2007) Nanoscale microelectrochemical cells on carbon nanotubes. Small 3(9):1513–1517. https://doi.org/10.1002/smll.200700139

Kang YJ, Chun S-J, Lee S-S, Kim B-Y, Kim JH, Chung H, Lee S-Y, Kim W (2012) All-solid-state flexible supercapacitors fabricated with bacterial nanocellulose papers, carbon nanotubes, and triblock-copolymer ion gels. ACS Nano 6(7):6400–6406. https://doi.org/10.1021/nn301971r

Ishikawa A, Okano T, Sugiyama J (1997) Fine structure and tensile properties of ramie fibres in the crystalline form of cellulose I, II, IIII and IVI. Polymer 38(2):463–468. https://doi.org/10.1016/S0032-3861(96)00516-2

Segal L, Creely J, Martin A, Conrad C (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29(10):786–794

Zhai Y, Dou Y, Zhao D, Fulvio PF, Mayes RT, Dai S (2011) Carbon materials for chemical capacitive energy storage. Adv Mater 23(42):4828–4850. https://doi.org/10.1002/adma.201100984

Ni J, Huang Y, Gao L (2013) A high-performance hard carbon for Li-ion batteries and supercapacitors application. J Power Sources 223:306–311. https://doi.org/10.1016/j.jpowsour.2012.09.047

Wu S-H, Chen D-H (2003) Synthesis and characterization of nickel nanoparticles by hydrazine reduction in ethylene glycol. J Colloid Interface Sci 259(2):282–286. https://doi.org/10.1016/S0021-9797(02)00135-2

Patil UM, Gurav KV, Fulari VJ, Lokhande CD, Joo OS (2009) Characterization of honeycomb-like “β-Ni(OH)2” thin films synthesized by chemical bath deposition method and their supercapacitor application. J Power Sources 188(1):338–342. https://doi.org/10.1016/j.jpowsour.2008.11.136

Zhi J, Reiser O, Huang F (2016) Hierarchical MnO2 spheres decorated by carbon-coated cobalt nanobeads: low-cost and high-performance electrode materials for supercapacitors. ACS Appl Mater Interfaces 8(13):8452–8459. https://doi.org/10.1021/acsami.5b12779

Jiang H, Li C, Sun T, Ma J (2012) High-performance supercapacitor material based on Ni(OH)2 nanowire-MnO2 nanoflakes core-shell nanostructures. Chem Commun 48(20):2606–2608. https://doi.org/10.1039/c2cc18079k

Xu X, Liu Y, Wang M, Zhu C, Lu T, Zhao R, Pan L (2016) Hierarchical hybrids with microporous carbon spheres decorated three-dimensional graphene frameworks for capacitive applications in supercapacitor and deionization. Electrochim Acta 193:88–95. https://doi.org/10.1016/j.electacta.2016.02.049

Lei W, Han L, Xuan C, Lin R, Liu H, Xin HL, Wang D (2016) Nitrogen-doped carbon nanofibers derived from polypyrrole coated bacterial cellulose as high-performance electrode materials for supercapacitors and Li-ion batteries. Electrochim Acta 210:130–137. https://doi.org/10.1016/j.electacta.2016.05.158

Acknowledgements

The authors would like to thank Scott Payne and Jayma Moore of the NDSU Electron Microscopy Center core facility for their assistance on SEM imaging. The imaging result is based upon work supported by the National Science Foundation under Grant Nos. 0619098, 0821655, 0923354, and 1229417. The authors are grateful for the scholarships provided by Materials and Nanotechnology Program and Mechanical Engineering Department, NDSU. The authors also thank Dr. Jian Wang for his generous supply of liquid nitrogen and Dr. Zhaohui Liu for his help with freeze drying.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Wang, Y. & Jiang, L. Freestanding carbon aerogels produced from bacterial cellulose and its Ni/MnO2/Ni(OH)2 decoration for supercapacitor electrodes. J Appl Electrochem 48, 495–507 (2018). https://doi.org/10.1007/s10800-018-1183-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-018-1183-5