Abstract

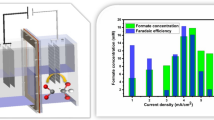

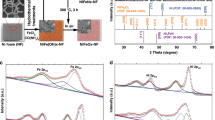

A continuous electrochemical process with integrated product separation has been developed for production of 2,5-furandicarboxylic acid (FDCA) by oxidation of 5-(hydroxymethyl)furfural (HMF) in aqueous alkaline media on non-noble Ni/NiOOH foam electrodes at ambient conditions. Initially, voltammetry studies were performed in both, acid and alkaline media, on various catalyst materials: Au, Au3Pd2, Pt, PbO2, Ni/NiOOH and graphite. Preparative electrolysis was performed on Au, Au3Pd2, Pt, PbO2, Ni/NiOOH electrodes in a divided glass cell and Ni/NiOOH showed the best performance with an FDCA yield of ≈ 90% and a Faradaic efficiency of ≈ 80%. The electrolysis conditions were then optimized to industrially relevant conditions in a filter-press type flow reactor with Ni/NiOOH foam anode. HMF concentrations as high as 10 wt% were converted to FDCA at pH 12 in a buffer free 0.1 M Na2SO4 electrolyte with continuous addition of NaOH to maintain constant pH. An FDCA separation yield up to 95% was achieved via pH shift crystallization. The electrolysis and FDCA separation results were used for the design and construction of a bench-scale system where continuous FDCA production, including integrated product separation, was tested and reported in this work. This publication for the first time presents a continuous electrochemical FDCA production system with integrated product separation at industrially relevant product concentrations, 10 wt% HMF, and utilizing non-noble electrode materials.

Graphical Abstract

Similar content being viewed by others

Notes

The net current densities were normalized to the geometric surface area of the working electrode and are baseline corrected, where baseline is the current density at the same potential without HMF present.

References

Fletcher K (2016) EIA releases 2016 international energy outlook. Biomass Magazine. http://biomassmagazine.com/articles/13249/eia-releases-2016-international-energy-outlook. Accessed 28 Oct 2017

Carmo M, Fritz D, Mergel J, Stolten D (2013) A comprehensive review on PEM water electrolysis. Int J Hydrog Energy 38:4901–4934. https://doi.org/10.1016/j.ijhydene.2013.01.151

Frontana-Uribe BA, Little RD, Ibanez JG, Palma A, Vasquez-Medrano R (2010) Organic electrosynthesis: a promising green methodology in organic chemistry. Green Chem 12:2099–2119. https://doi.org/10.1039/C0GC00382D

Cha HG, Choi KG (2015) Combined biomass valorization and hydrogen production in a photoelectrochemical cell. Nature Chem 7:328–333. https://doi.org/10.1038/nchem.2194

Werby T, Petersen G (2004) Top added value chemicals from biomass, U.S. Department of energy, 2004

de Jong E et al (2013) Biobased monomers, polymers and materials. OUP USA

Avantium (2016) Avantium press release. https://www.avantium.com/press-releases/synvina-joint-venture-basf-avantium-established/. Accessed 28 Oct 2017

Davis SE, Houk LR, Tamargo EC, Datye AK, Davis RJ (2011) Oxidation of 5-hydroxymethylfurfural over supported Pt, Pd and Au catalysts. Catal Today 160:55–60. https://doi.org/10.1016/j.cattod.2010.06.004

Villa A, Schiavoni M, Campisi S, Veith GM, Prati L (2013) Pd-modified Au on carbon as an effective and durable catalyst for the direct oxidation of HMF to 2,5-furandicarboxylic acid. ChemSusChem 6:609–612. https://doi.org/10.1002/cssc.201200778

Jiang N, You B, Boonstra R, Terrero Rodriguez RM, Sun Y (2016) Integrating electrocatalytic 5-hydroxymethylfurfural oxidation and hydrogen production via Co–P-derived electrocatalysts. ACS Energy Lett 1:386–390. https://doi.org/10.1021/acsenergylett.6b00214

Verdeguer P, Merat N, Gaset A (1993) Oxydation catalytique du HMF en acide 2, 5-furane dicarboxylique. J Mol Catal 85:327–344. https://doi.org/10.1016/0304-5102(93)80059-4

Casanova O, Iborra S, Corma A (2009) Biomass into chemicals: aerobic oxidation of 5-hydroxymethyl-2-furfural into 2,5-furandicarboxylic acid with gold nanoparticle catalysts. ChemSusChem 2:1138–1144. https://doi.org/10.1002/cssc.200900137

van Deurzen MPJ (1997) Chloroperoxidasecatalyzed oxidation of 5-hydroxymethylfurfural. J Carbohydr Chem 16:299–309. https://doi.org/10.1080/07328309708006531

Hanke PD (2009) Enzymatic oxidation of HMF. 2009/023174 A2. USA

Koopman F (2010) Efficient whole-cell biotransformation of 5-(hydroxymethyl)furfural into FDCA, 2,5-furandicarboxylic acid. Bioresour Technol 101:6291–6296. https://doi.org/10.1016/j.biortech.2010.03.050

Zhang Z, Deng K (2015) Recent advances in the catalytic synthesis of 2,5-furandicarboxylic acid and its derivatives. ACS Catal 5:6529–6544. https://doi.org/10.1021/acscatal.5b01491 PL161831

Saha B, Dutta S, Abu-Omar MM (2012) Aerobic oxidation of 5-hydroxylmethylfurfural with homogeneous and nanoparticulate catalysts. Cat Sci Technol 2:79–81. https://doi.org/10.1039/c1cy00321f

Miura T, Kakinuma H, Kawano T, Matsuhisa H (2007) Method for producing furan-2,5-dicarboxylic acid. US 0232815, 2007

Li S, Su K, Li Z, Chenga B (2016) Selective oxidation of 5-hydroxymethylfurfural with H2O2 catalyzed by a molybdenum complex. Green Chem 18:2122–2128. https://doi.org/10.1039/C5GC01991E

Chadderdon DJ et al (2014) Electrocatalytic oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid on supported Au and Pd bimetallic nanoparticles. Green Chem 16:3778–3786. https://doi.org/10.1039/C4GC00401A

Vuyyuru K, Strasser P (2012) Oxidation of biomass derived 5-hydroxymethylfurfural using heterogeneous and electrochemical catalysis. Catal Today 195:144–154. https://doi.org/10.1016/j.cattod.2012.05.008

Grabowski G, Lewkowski J, Skowroński R (1991) The electrochemical oxidation of 5-hydroxymethylfurfural with the nickel oxide/hydroxide electrode. Electrochim Acta 36:1995. https://doi.org/10.1016/0013-4686(91)85084-K

Grabowski G, Lewkowski J, Skowronski R (1993) Method of obtaining 2,5-furanedicarboxylic acid. Patent PL161831, 1993

Manandhar K, Pletcher D (1979) The preparation of high surface area nickel oxide electrodes for synthesis. J Appl Electrochem 6:707–713. https://doi.org/10.1007/BF00614964

Briggs G et al (1956) The nickel oxide electrode. Trans Faraday Soc 51:1433–1442. doi:0.1039/TF9555101433

Al Baradii A, Kokoh KB, Lamy C, Leger JM (1999) Selective electrocatalytic oxidation of 2,5-dihydroxymethylfuran in aqueous medium: a chromatographic analysis of the reaction products. Electrochim Acta 44:2779. https://doi.org/10.1016/S0013-4686(99)00006-7

Kokoh KB, Belgsir EM (2002) Electrosynthesis of furan-2,5-dicarbaldehyde by programmed potential electrolysis. Tetrahedron Lett 43:229–231. https://doi.org/10.1016/S0040-4039(01)02106-2

Monahov B, Pavlov D, Kirchev A, Vasilev S (2003) Influence of pH of the H2SO4 solution on the phase composition of the PbO2 active mass and of the PbO2 anodic layer formed during cycling of lead electrodes. J Power Sources 2:281:292. https://doi.org/10.1016/S0378-7753(02)00583-9

Devilliers D, Dinh Thi MT, Mahe E, Dauriac V, Lequeux N (2004) Electroanalytical investigations on electrodeposited lead dioxide. J Electroanal Chem 573:227–239. https://doi.org/10.1016/j.jelechem.2004.07.008

Lai SCS et al (2010) Effects of electrolyte pH and composition on the ethanol electro-oxidation reaction. Catal Today 154:92–104. https://doi.org/10.1016/j.cattod.2010.01.060

Wang W, Savadogo O, Ma ZF (2012) The oxygen reduction reaction on Pt/TiOxNy-based electrocatalyst for PEM fuel cell applications. J Appl Electrochem 42:857:866. https://doi.org/10.1007/s10800-012-0452-y

Arenas LF, Ponce de León C, Boardman RP, Walsh FC (2017) Characterisation of platinum electrodeposits on a titanium micromesh stack in a rectangular channel flow cell. Electrochim Acta 247:994–1005. https://doi.org/10.1016/j.electacta.2017.07.029

Pereira JF, Figueiredo RS, Ponce-de-León C, Bertazzoli R (2016) Platinum-free lead dioxide electrode for electrooxidation of organic compounds. J Solid State Electrochem 20:1167–1173. https://doi.org/10.1007/s10008-015-2950-4

Fleszar B, Ploszynska J (1985) Electrochim Acta 30:31

Trabelsi SK, Belhadj Tahar N, Trabelsi B, Abdelhedi R (2005) Electrochemical oxidation of ferulic acid in aqueous solutions at gold oxide and lead dioxide electrodes. J Appl Electrochem 35:967–973. https://doi.org/10.1007/s10800-005-6723-0

Latsuzbaia R, Negro E, Koper GJM (2015) Environmentally friendly carbon-preserving recovery of noble metals from supported fuel cell catalysts. ChemSusChem 8:1926–1934. https://doi.org/10.1002/cssc.201500019

Cherevko S et al (2015) Dissolution of noble metals during oxygen evolution in acidic media. ChemSusChem 2:1471–1478. https://doi.org/10.1002/cctc.201402194

Zhou X, Xu W, Liu G, Panda D, Chen P (2010) Size-dependent catalytic activity and dynamics of gold nanoparticles at the single-molecule level. JACS 132:138–146. https://doi.org/10.1021/ja904307n

Oliveira VL et al (2015) Kinetic investigations of glycerol oxidation reaction on Ni/C. Electrocatalysis 6:447–454. https://doi.org/10.1007/s12678-015-0261-2

Nanzer J, Langlois S, Coeuret F (1993) Preparation and use of a nickel foam electrode for the production of diacetone-2-keto-l-gulonic acid from diacetone-l-sorbose in vitamin C production. J Appl Electrochem 23:471–476. https://doi.org/10.1007/BF00707624

Drunen J et al (2013) Comprehensive structural, surface-chemical and electrochemical characterization of nickel-based metallic foams. ACS Appl Mater Interfaces 5:6712–6722. https://doi.org/10.1021/am401606n

Lyalin BV, Petrosyan VA (2010) Oxidation of organic compounds on NiOOH electrode. Russ J Electrochem 46:1199–1214. https://doi.org/10.1134/S1023193510110017

Motheo AJ, Tremiliosi-Filho G, Gonzalez ER, Kokoh KB, Léger JM, Lamy C (2006) Electrooxidation of benzyl alcohol and benzaldehyde on a nickel oxy-hydroxide electrode in a filter-press type cell. J Appl Electrochem 36:1035–1041. https://doi.org/10.1007/s10800-006-9156-5

Couper AM, Pletcher D, Walsh FC (1990) Electrode materials for electrosynthesis. Chem Rev 90:837–865

Pletcher D, Walsh FC (1990) Industrial electrochemistry, 2nd edn. Chapman and Hall, London

Ralph TR, Hitchman ML, Peter Millington JP, Walsh FC (2005) The importance of batch electrolysis conditions during the reduction of l-cystine hydrochloride. J Electrochem Soc 152:D54-D63. https://doi.org/10.1149/1.1858831

Horvat J et al (1985) Mechanism of levunilic acid formation. Tetrahedron Lett 26:2111–2114. https://doi.org/10.1016/S0040-4039(00)94793-2

Lewkowski J (2001) Synthesis, chemistry and applications of 5 hydroxymethylfurfural and its derivatives. ARKIVOC 1:17–54. https://doi.org/10.3998/ark.5550190.0002.102

Walsh F, Reade G (1994) Design and performance of electrochemical reactors for efficient synthesis and environmental treatment part 1. Electrode geometry and figures of merit. Analyst 119:791–796. https://doi.org/10.1039/AN9941900791

Acknowledgements

We acknowledge financial support from the Voltachem Shared Innovation Program (http://www.voltachem.com/).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Latsuzbaia, R., Bisselink, R., Anastasopol, A. et al. Continuous electrochemical oxidation of biomass derived 5-(hydroxymethyl)furfural into 2,5-furandicarboxylic acid. J Appl Electrochem 48, 611–626 (2018). https://doi.org/10.1007/s10800-018-1157-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-018-1157-7