Abstract

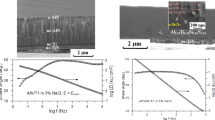

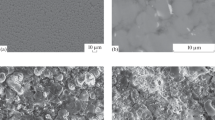

X-ray photoelectron spectroscopy (XPS) was used to analyze the composition of films at different deposition parameters of sputtered Al-Ce coatings on AA6061 aluminum alloys. By means of electrochemical impedance spectroscopy (EIS) measurements, the protective character of these coatings was studied for 21 days of exposure in a 3.5 wt% NaCl solution and an attempt was made to establish the relationship between film thickness and chemical composition (Al/Ce, Ce3/Ce4+ ratios) of the surface before and after the electrochemical characterization. XPS studies revealed the presence of the Alo, Al2O3, CeO2 and Ce2O3 compounds, confirming that the sputtered Al-Ce films were deposited in the metallic form and thereafter were superficially oxidized under ambient conditions. The Al–Ce bonds were overlapped with the signal of cerium oxides. The transport phenomena in the oxide film or controlled diffusion process are strongly dependent on the deposition parameters and exposure time in the aggressive medium. It was also found that in the deposited samples at p4P200t300, the film was still present after 21 days of exposure, although with visible cracks and erosion areas; however, the Ce3/Ce4+ ratio almost remained constant before and after the electrochemical characterization, which explained the barrier properties of these samples as compared with others at different deposition parameters.

Similar content being viewed by others

References

Szklarska-Smialowska Z (1999) Corros Sci 41:1743

Sun X, Zhou X, Thompson GE, Skeldon P, Shimizu K, Furneaux RC, Scamans G (1998) Sixth international conference on aluminium alloys vol 3, p 1571

Davis JR (ed) (1999) Corrosion of aluminium and aluminium alloys. ASM International, Materials Park

Habazaki H, Shimizu K, Skeldon P, Thompson GE, Wood GC, Zhou X (1997) Corros Sci 39:731

Mujibur Rahman ABM, Kumar S, Gerson AR (2008) Corros Sci 50:1267

Voevodin N, Jeffcoate C, Simon L, Khobaib M, Donley M (2001) Surf Coat Technol 140:29

Sander LS, Musingo EM, Neill WJ (1990) US Patent 4,921,552

Das N (1992) US Patent 5,139,586

Miller RN (1994) US Patent 5,356,492

Tomlinson CE (1995) US Patent 5,380,374

Hinton BRW, Arnott DR, Ryan NE (1986) Mater Forum 9:162

Mansfeld F, Lin S, Kim S, Shih H (1989) Electrochim Acta 34:1123

Domínguez-Crespo MA, Rodil SE, Torres-Huerta AM, Ramírez-Meneses E, Suárez-Velázquez G (2009) Surf Coat Technol 204:571

Sheng HW, Liu HZ, Cheng YQ, Wen J, Lee PL, Luo WK, Shastri SD, Ma E (2007) Nat Mater 6:192

Mazurkiewicz B, Piotrowski A (1983) Corros Sci 23:697

Blanc C, Lavelle B, Mankowski G (1996) Mater Sci Forum 217:1559

Vyazovikina NV (1999) Protect Met 35:448

Okamoto G, Shibata T (1978) In: Frankenthal RP, Kruger J (eds) Passivity of metals, Corrosion monograph series, The Electrochemical Society, Pennington, NJ

Blanc C, Mankowski G (1997) Corros Sci 39:949

Blanc C, Lavelle B, Mankowski G (1997) Corros Sci 39:495

Aballe A, Bethencourt M, Botana FJ, Cano MJ, Marcos M (2001) Corros Sci 43:1657

Bethencourt M, Botana FJ, Calvino JJ, Marcos M, Rodriguez MA (1998) Mater Sci Forum 289–292:567

Ambat R, Dwarakadasa ES (1994) J Appl Electrochem 24:911

Wallinder D, Pan J, Leygraf C, Delblanc-Bauer A (1999) Corros Sci 41:275

Yu X, Li G (2004) J Alloys Compd 264:193

Pan M, Meng GY, Xin HW, Chen CS, Peng DK, Lin YS (1998) Thin Solid Films 324:89

Pardo A, Merino MC, Arrabal R, Viejo F, Munoz JA (2007) Appl Surf Sci 253:3334

Teterin YA, Teterin AY, Lebedev AM, Utkin IO (1998) J Electron Spectrosc Relat Phenom 88–91:275

Arnott DR, Ryan NE, Hinton BRW, Sexton BA, Hughes AE (1985) Appl Surf Sci 22–23:236

Yu X, Li G (2004) J Alloys Compd 364:193

Domínguez-Crespo MA, Torres-Huerta AM, Rodil SE, Ramírez-Meneses E, Suárez-Velázquez G, Hernández-Pérez MA (2009) Electrochim Acta 55:498

Goeminne G, Terryn H, Vereecken J (1998) Electrochim Acta 43:1829

Campestrini P, Westing V, Wit JH (2001) Electrochim Acta 46:2631

Goeminne G, Terryn H, Vereecken J (1995) Electrochim Acta 40:479

Moutarlier V, Gigandet MP, Normand, Pagetti BJ (2005) Corros Sci 47:937

Palomino LEM, Aoki IV, de Melo HG (2006) Electrochim Acta 51:5943

López DA, Simison SN, de Sánchez SR (2005) Corros Sci 47:735

Bilkova K, Hackerman N, Bartos M (2002) Proceedings of the NACE corrosion, paper no. 2284, Denver, CO

Scully JR (1993) Electrochemical impedance: analysis and interpretation. ASTM STP 1188, p 26

Bessone JB, Salinas DR, Mayer CE, Ebert M, Lorenz WJ (1992) Electrochim Acta 37:2283

Xingwen Y, Chunan C, Zhiming Y, Derui Z, Zhongda Y (2001) Corros Sci 43:1283

Hughes AE, Gorman JD, Patterson PJK (1996) Corros Sci 38:1957

Gorman JD, Jhonson ST, Joghnston PN, Patterson PJK, Hughes AE (1996) Corros Sci 38:1977

Scully JC (1990) The fundaments of corrosion, 3rd edn. Pergamon Press, Oxford

Zaid B, Saidi D, Benzaid A, Hadji S (2008) Corros Sci 50:1841

Meng G, Wei L, Zhang T, Shao Y, Wang F, Dong C, Li X (2009) Corros Sci 51:2151

Ren J, Zuo Y (2005) Surf Coat Technol 191:311

Yu SY, O’Grady WE, Ramaker DE, Natishan PM (2000) J Electrochem Soc 147:2952

Pyun SI, Lee WJ (2001) Corros Sci 43:153

Moutarlier V, Gigandet MP, Pagetti J (2003) Appl Surf Sci 206:237

Zhang H, Zuo Y (2008) Appl Surf Sci 254:4930

Acknowledgments

This study has been financially supported by CONACYT (project number 61354), IPN (projects number SIP-2009-0561, 2009-0499) and SNI. The authors would like to thank Mr. Javier Zapata Torres for his technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Domínguez-Crespo, M.A., Torres-Huerta, A.M., Rodil, S.E. et al. XPS and EIS studies of sputtered Al–Ce films formed on AA6061 aluminum alloy in 3.5% NaCl solution. J Appl Electrochem 40, 639–651 (2010). https://doi.org/10.1007/s10800-009-0039-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-009-0039-4