Abstract

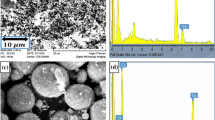

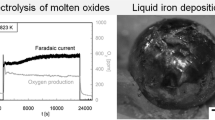

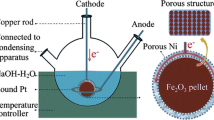

Iron(III) oxide tablets were electrolytically reduced to iron in molten sodium hydroxide at 530 °C and recovered to produce iron with 2 wt.% oxygen suitable for re-melting. The cell was operated at 1.7 V and an inert nickel anode was used. The thermodynamics and mechanism of the process was also investigated. By controlling the activity of sodium oxide in the melt, the cell could be operated below the decomposition voltage of the electrolyte with the net sequence of events being the ionization of oxygen, its subsequent transport to the anode and discharge leaving behind iron at the cathode. A reduction time of 1 h was achieved for a 1 g oxide tablet (close to the theoretical reduction time predicted by Faraday’s laws) at a current density of 520 mA cm−2 with iron phase yields of ∼90 wt.%. The energy consumption was 2.8 kWh kg−1.

Similar content being viewed by others

References

Industries (2006) E.C.o.I.a.S

Chen GZ, Fray DJ, Farthing TW (2000) Nature 407:361–364

Burheim OS (2005) Institutt for Material Teknologi, University of Trondheim

Plambeck JA (1976) Encyclopedia of electrochemistry of the elements. Marcel Dekker

Newell LC (1904) Descriptive chemistry. Heath

Tremillon B (1971) Pure Appl Chem 25:395

Schwandt C, Fray DJ (2005) Electrochimica Acta 51:66–76

Yan XY, Fray DJ (2005) J Electrochem Soc 152:D12–D21

Bouaziz R, Papin G, Rollet AP (1966) C R Acad Sci Ser C 262:1053

Acknowledgements

The authors are grateful to the EPSRC for funding (Platform Grant GR/S58447/01) the work in this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cox, A., Fray, D.J. Mechanistic investigation into the electrolytic formation of iron from iron(III) oxide in molten sodium hydroxide. J Appl Electrochem 38, 1401–1407 (2008). https://doi.org/10.1007/s10800-008-9579-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-008-9579-2