Abstract

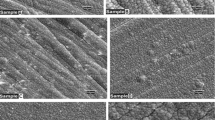

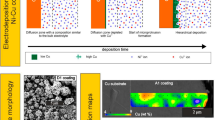

Ni–Mo nanocrystalline layers were electrodeposited using direct current from citrate–ammonia solutions. The quartz crystal microbalance investigation confirms that the discharge process starts with hydrogen evolution before the onset of the alloy deposition. The grain size was estimated from X-ray line broadening. It decreases when the molybdenum content is increased. It is smaller for layers deposited at pH 9.5 than 8.5. The microhardness exhibits a maximum close to 800 Vickers for τMo around 17 wt%. For higher τMo a softening is observed showing a deviation from Hall-Petch behaviour due to small grain size. In deaerated hydrochloric solutions, the layers show a large passivation domain without any pitting. The corrosion currents as well as the passivation currents, higher than for the bulk Hastelloy B alloy, decrease when τMo is increased.

Similar content being viewed by others

References

C. Suryanarayana, Int. Mat. Rev. 40 (1995) 41 and references therein.

U. Erb, A.M. El-Sherik, G. Palumbo and K.T. Aust, Nanostruct. Mater. 2 (1993) 383.

E. Chassaing, M.P. Roumegas and M.F. Trichet, J. Appl. Electrochem. 25 (1995) 667.

E.J. Podlaha, M. Matlosz and D. Landolt, J. Electrochem.Soc. 140 (1993) L149.

S. Rengakuji, Y. Nakamura, N. Sumi, K. Nishibe and T. Komura, Denki Kagaku 63 (1995) 400.

Y. Zeng, Z. Li, M. Ma, S. Zhou, Electrochem. Comm. 2 (2000) 36.

L.S. Sanches, S.H. Domingues, A. Carubelli and L.H. Mascaro, J. Brazilian Chem. Soc. 14 (2003) 556.

W.Z. Friend, in Corrosion of Nickel and Nickel-base Alloys (Wiley-Interscience publication, New York, 1980), p. 248.

C.L. Fan, D.L. Piron, A. Sleb and P. Paradis, J. Electrochem. Soc. 141 (1994) 382.

Y.C. Chang, K.C. Fan and C.I. Lin, J. Chin. Inst. Chem. Eng. 33 (2002) 499.

T.Sato, H. Takahashi, E. Matsubara and A. Muramatsu, Mat. Trans. 43 (2002) 1525.

A. Brenner, in Electrodeposition of Alloys, Vol. II Academic Press, 1963, pp. 347–408.

E.Chassaing, K. Vu Quang and R. Wiart, J. Appl. Electrochem. 19 (1989) 839.

S. Rengakuji, Y. Nakamura, K. Nishibe, M. Inoue and T. Komura, Denki Kagaku 62 (1994) 602.

E.J. Podlaha and D. Landolt, J. Eectrochem. Soc. 144 (1997) 1672.

E.Gomez, E. Pellicer and E. Valles, J. Appl. Electrochem. 33 (2003) 245.

C. Suryanarayana and C.C. Koch, Hyperfine Interact. 130 (2000) 5.

W.B. Pearson, A Handbook of Lattice Spacings and Structures of Metals and Alloys, Vol. 2 (Pergamon Press, 1967).

T. Yamasaki, P. Schlossmacher, K. Ehrlich and Y. Ogino, Nanostruct. Mater. 10 (1998) 375.

T.Yamasaki, R. Tomohira, Y. Ogino, P. Schlossmacher and K. Ehrlich, Plating Surf. Finish. 87 (2000) 148.

G. Palumbo, S.J. Thorpe and K.T. Aust, Scri. Met. et Mat. 24 (1990) 1347.

R. Rofagha, R. Langer, A. M. El-Sherik, U. Erb, G.Palumbo and K.T. Aust, Scri. Met. et Mater. 25 (1991) 2867.

R. Rofagha, U. Erb, D. Ostrander, G. Palumbo and K.T. Aust, Nanostruct. Mater. 2 (1993) 1.

R. Rofagha, S.J. Splinter, U. Erb and N.S. McIntyre, Nanostruct. Mater. 4 (1994) 69.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chassaing, E., Portail, N., Levy, Af. et al. Characterisation of electrodeposited nanocrystalline Ni–Mo alloys. Journal of Applied Electrochemistry 34, 1085–1091 (2004). https://doi.org/10.1007/s10800-004-2460-z

Issue Date:

DOI: https://doi.org/10.1007/s10800-004-2460-z