Abstract

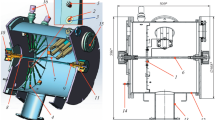

A design for a facility for the surface treatment of metal samples is described, and the results from investigating the source of a high-current low-energy electron beam are presented. The electron beam, which has a current as high as 300 A, a pulse duration of 30 µs, and a pulse repetition rate of up to 10 Hz, is formed in a plasma-cathode gas-filled diode at an accelerating voltage of ∼20 kV. The space-charge compensated electron beam is transported a distance of 20 cm in a longitudinal magnetic field to the region of its interaction with a solid body. At a current density as high as 100 A/cm2, the power density produced by the beam is sufficient for the metal surface to be melted in the duration of one or several pulses. Samples can be replaced in the facility without breaking the vacuum.

Similar content being viewed by others

REFERENCES

Ozur, G.E., Proskurovsky, D.I., Rotshtein, V.P., and Markov, A.B., Laser Part. Beams, 2003, vol. 21, p. 157.

Engelko, V., Yatsenko, B., Mueller, G., and Bluhm, H., Vacuum, 2001, vol. 62/2–3, p. 211.

Koval’, N.N., Kreindel’, Yu.E., and Shchanin, P.M., Zh. Tekh. Fiz., 1983, vol. 53, no.9, p. 1846 [Sov. J. Tech. Phys. (Engl. Transl.), 1983, vol. 28, no. 9, p. 1133].

Devyatkov, V.N., Koval’, N.N., and Shchanin, P.M., Izv. Vyssh. Uchebn. Zaved., Ser. Fiz., 2001, vol. 44, no.9, p. 36.

Devyatkov, V.N., Koval, N.N., and Schanin, P.M., Proc. 7th Int. Conf. on Electron Beam Technologies, Varna, Bulgaria, 2003, p. 125.

Rossa, J.J., Szapio, D., and Verhey, T., Appl. Phys. Lett., 1987, vol. 50, p. 1334.

Devyatkov, V.N., Koval’, N.N., and Shchanin, P.M., Zh. Tekh. Fiz., 2001, vol. 71, no.5, p. 20 [Tech. Phys. (Engl. Transl.), 2001, vol. 46, no. 5, p. 524].

Debnovetsky, S.V., Melnik, V.I., Melnik, I.V., et al., Abstracts of Papers, 7th Int. Conf. on Electron Beam Technologies, Varna, Bulgaria, 2003, p. 139.

Author information

Authors and Affiliations

Additional information

Translated from Pribory i Tekhnika Eksperimenta, No. 1, 2005, pp. 135–140.

Original Russian Text Copyright © 2004 by Koval’, Shchanin, Devyatkov, Tolkachev, Vintizenko.

Rights and permissions

About this article

Cite this article

Koval’, N.N., Shchanin, P.M., Devyatkov, V.N. et al. A facility for metal surface treatment with an electron beam. Instrum Exp Tech 48, 117–121 (2005). https://doi.org/10.1007/s10786-005-0023-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s10786-005-0023-0