Abstract

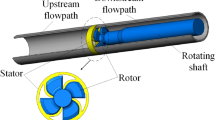

Aim at improving the energy saving and transmission efficiency of directional drilling rig, the load sensing technology and constant-pressure variable technique are adopted to enable the system to provide the required pressure and flow rate according to the load variation. In order to research the dynamic characteristics of hydraulic control systems, the background and working principle of the load sensing technology were introduced. The dynamic mathematical model of load sensing system is established based on the hydraulic principle. The directional drilling rig mainly consists of two basic circuits: rotary circuit and feed circuit. The dynamic characteristics of rotary circuit are mainly studied. In addition, the hydraulic system of kilometres directional rig is simulated with the software of AMESim. The simulation results show that the load sensing pump could output its required flow and outlet pressure adapted to the load pressure in real time, thus effectively improving the efficiency of the hydraulic system. Furthermore, to verify the validity of the mathematical model and the simulation analysis, an experimental platform of the load sensing hydraulic system was built. The dynamic performance test of load sensing hydraulic system was performed by using the platform. The experimental results demonstrated that the load sensing hydraulic system could output its required flow and pressure when the working condition changed. Finally, they also illustrate the validity of the proposed approach.

Similar content being viewed by others

References

X. Wu, H. Song and X. Yin, Simulation analysis of drilling load sensing system based on AMESim, Machine Tool and Hydraulics, Vol. 36, No. 3, pp. 163–164+195, 2008.

N. Z. Aung, Q. Yang, M. Chen, et al., CFD analysis of flow forces and energy loss characteristics in a flapper nozzle pilot valve with different null clearances, Energy Conversion and Management, Vol. 83, pp. 284–295, 2014.

V. Dossena, F. Marinoni, F. Bassi, et al., Numerical and experimental investigation on the performance of safety valves operating with different gases, International Journal of Pressure Vessels and Piping, Vol. 104, pp. 21–29, 2013.

S. D. Kim, H. S. Cho and C. O. Lee, Stability analysis of a load sensing hydraulic system, Proceedings of the Institute of Mechanical Engineers, Vol. 202, No. A2, pp. 79–88, 1988.

S. H. Cho and P. Noskievič, Position tracking control with load-sensing for energy-saving valve-controlled cylinder system, Journal of Mechanical Science and Technology, Vol. 26, No. 2, pp. 617–625, 2012.

X. Wang, J. Hu, W. Gao, et al., Mathematical modeling and analysis of load sensitive multi-way valve, Hydraulics Pneumatics and Seals, Vol. 11, pp. 15–17, 2013.

C. Capponi, M. Ferrante, M. Pedroni, et al., Real data analysis and efficiency of the TEA Mantova Casale (Italy) variable speed pumping station, Procedia Engineering, Vol. 70, pp. 248–255, 2014.

P. Casoli and A. Anthony, Simulation of simultaneous propagation of multiple hydraulic fractures in horizontal wells, Journal of Petroleum Science and Engineering, Vol. 147, No. 11, pp. 788–800, 2016.

G. Coskun, T. Kolcuoglu, T. Dogramacı, et al., Analysis of a priority flow control valve with hydraulic system simulation model, Journal of Brazilian Society of Mechanical Sciences and Engineering, Vol. 39, pp. 1597–1605, 2017.

D. X. Ba, K. K. Ahn, D. Q. Truong and H. G. Park, Integrated model-based backstepping control for an electro-hydraulic system, International Journal of Precision Engineering and Manufacturing, Vol. 17, No. 5, pp. 565–577, 2016.

A. Ylinen, H. Marjamäki and J. Mäkinen, A hydraulic cylinder model for multibody simulations, Computers and Structures, Vol. 138, No. 7, pp. 62–72, 2014.

X. Yu, J. Zhang, C. Fan and S. Chen, Stability analysis of governor-turbine-hydraulic system by state space method and graph theory, Energy, Vol. 114, No. 11, pp. 613–622, 2016.

J. Yin and L. Mei, Fault diagnosis of excavator hydraulic system based on expert system, Advances in Automation and Robotics, LNEE, Vol. 122, No. 1, pp. 87–92, 2012.

K. K. Ahn, D. N. C. Nam and M. Jin, Adaptive backstepping control of an electrohydraulic actuator, IEEE/ASME Transactions on Mechatronics, Vol. 19, No. 3, pp. 987–995, 2014.

M. Muvengei and J. Kihiu, Bond Graph modeling of inter-actuator interactions in multi-cylinder hydraulic system, International Journal of Aerospace and Mechanical Engineering, Vol. 5, No. 3, pp. 147–156, 2011.

P. Olivier, C. Bourasseau and B. Bouamama, Dynamic and multi-physic PEM electrolysis system modelling: a bond graph approach, International Journal of Hydrogen Energy, Vol. 42, No. 22, pp. 14872–14904, 2017.

G. Yong, L. Deshun, Y. Shuyi, L. Xuejun and C. Jianwen, Hydraulic–mechanical coupling modeling by bond graph for impact system of a high frequency rock drill drifter with sleeve distributor, Automation in Construction, Vol. 63, No. 3, pp. 88–99, 2016.

H. Cheung and J. E. Braun, Component-based, gray-box modeling of ductless multi-split heat pump systems, International Journal of Refrigeration, Vol. 38, No. 1, pp. 30–45, 2014.

J. Hu and K. Li, Thermal-hydraulic modeling and analysis of hydraulic system by pseudo-bond graph, Journal of Central South University, Vol. 22, No. 7, pp. 2578–2585, 2015.

M. Turkseven and J. Ueda, An asymptotically stable pressure observer based on load and displacement sensing for pneumatic actuators with long transmission lines, IEEE-ASME Transactions on Mechatronics, Vol. 22, No. 2, pp. 681–692, 2017.

Q. Hu, H. Zhang and S. Tian, Model reduction of a load-sensing hydraulic system via activity index analysis, Stroniski Vestnik-Journal of Mechanical Engineering, Vol. 63, No. 1, pp. 65–77, 2017.

Y. Lu, M. Liu and Y. Liu, Modeling and simulation of a new type hydraulic system on CVT, Lecture Notes in Electrical Engineering, Vol. 193, pp. 349–359, 2013.

J. Yao, B. Li, X. Kong and F. Zhou, Displacement and dual-pressure compound control for fast forging hydraulic system, Journal of Mechanical Science and Technology, Vol. 30, No. 1, pp. 353–363, 2016.

F. Huang and Y. M. Xu, Modeling and simulation of pressure-flow compound control electro-hydraulic system power source, Machine Tool and Hydraulics, Vol. 39, No. 11, pp. 125–130, 2011.

J. R. Valdés, J. M. Rodríguez, R. Monge, et al., Numerical simulation and experimental validation of the cavitating flow through a ball check valve, Energy Conversion and Management, Vol. 78, pp. 776–786, 2014.

L. Wang, W. J. Book and J. D. Huggins, Application of singular perturbation theory to hydraulic pump controlled systems, IEEE/ASME Transactions on Mechatronics, Vol. 17, No. 2, pp. 251–259, 2012.

Acknowledgements

The authors acknowledge the National Natural Science Foundation of China (Grant: 51275061), the National Natural Science Foundation of China (Grant: 61672121), the Doctoral Scientific Research Foundation of Liaoning Province (Grant: 20141121), Science and Technology Research Foundation of the Educational Department of Liaoning Province (Grant: LS2010006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J. Structural Modeling and Performance Analysis of Rotary Circuit in Directional Drilling Rig Based on Load Sensing Technology. Int J Wireless Inf Networks 25, 269–278 (2018). https://doi.org/10.1007/s10776-017-0382-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10776-017-0382-z