Abstract

Polyimide foam (PF) is a low-thermal conductivity and lightweight material with high resistances against heat, protons, and UV irradiation. A new thermal insulation composed of PFs and multiple aluminized films (PF–MLI) has potential to be used in outer space as an alternative to conventional multilayer insulation (MLI). As fundamental numerical data, the effective thermal conductivity of PF in wide ranges of density and temperature need to be determined. In the present study, thermal-conductivity measurements were performed by both the periodic heating method and the guarded hot-plate method in the temperature range from 160 K to 370 K and the density range from 6.67 \(\mathrm{kg} \cdot \mathrm{m}^{-3}\) to 242.63 \(\mathrm{kg}\cdot \mathrm{m}^{-3}\). The experiments were carried out in a vacuum and under atmospheric pressure. For confirmation of the validity of the present guarded hot-plate apparatus under atmospheric pressure, the effective thermal conductivity of the lowest-density PF was measured with the aid of the heat flow meter apparatus calibrated by the standard reference material (NIST SRM 1450c) in the temperature range from 303 K to 323 K. In order to cross-check the present experimental results, the temperature and density dependences of the effective thermal conductivity of PF were estimated by means of the lattice Boltzmann method based on a dodecahedron inner microscopic complex structure model which reflects a real 3D X-ray CT image of PF.

Similar content being viewed by others

1 Introduction

Multilayer insulation (MLI), which prevents both excess heat loss from a component and excess heat gain from a space environment, is the most common thermal-control element on spacecraft. MLI is composed of multiple layers of thin, low-emissivity metalized films and low-conductive polyester net spacers between the layers. Heat transfer across MLI is a combination of radiation between the layers and heat conduction through solid elements. The radiative heat transfer can be minimized by interposing reflective multilayers. Even though the heat conduction can be reduced by employing the low-conductance spacers (polyester net) between the reflective layers, the heat loss through the seams in MLI is not negligible. For example, Okazaki et al. [1] estimated the heat loss through seams at 50 % of the total heat loss across MLI.

In this connection, we propose a new type of insulation using polyimide foam (PF) in order to decrease the heat loss through seams. The new insulation with polyimide foam (PF-MLI) is composed of multiple aluminized films and PFs. PF is a lightweight and low-thermal conductivity, shape-holding porous material. Since the PF-MLI can be designed without the seams, it possesses the potential to be used as a more desirable thermal insulation element than the conventional MLI. Prior to the design of PF-MLI, the effective thermal conductivity of PF in wide ranges of density and temperature should be determined as critical fundamental numerical information. There have been a number of studies on the effective thermal conductivity of foam insulations at atmospheric conditions [2–7]; however, experimental studies at vacuum conditions are very few. The purpose of the present study is to evaluate the effective thermal conductivity of PF itself in a high-vacuum condition. Thermal-conductivity measurements were performed by both the periodic heating method [4] and the guarded hot-plate method. In addition, we directly calculate the temperature and density dependences of the effective thermal conductivity of PF by means of the lattice Boltzmann method based on a dodecahedron inner microscopic structure model which reflects a 3D X-ray CT image of the actual PF in order to cross-check the present experimental results [5–7], because there are no approved standard reference porous materials for the thermal conductivity (of the order of \(10^{-3}\,\mathrm{W} \cdot \mathrm{m}^{-1} \cdot \mathrm{K}^{-1})\) at vacuum conditions.

2 Characteristic of Polyimide Foam

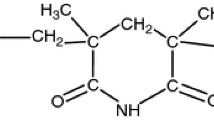

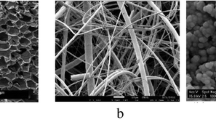

The PF under the trade name of UPILEX\(^{\circledR }\) produced by UBE Industries, Ltd. has characteristics of high heat resistance (up to 674 K), high durability against protons, electrons and UV irradiation, high electrical insulation capability, low outgas, and low density. Thus, it holds significant potential to be utilized for thermal insulation on spacecraft in various situations [8]. For estimation and measurement of the effective thermal conductivity of PFs in the present study, four different types of PF are provided. The nominal density ranges of the four types of PF according to Ref. [8] are listed in Table 1. Figures 1 and 2 show a bulk appearance and an inner structure scanning electron microscope (SEM) image of the lightest PF BF301, respectively. As can be seen from Fig. 2, the cells observed in BF301 have random polyhedral structures. BF301 is generated by expanding polyimide resin in order to produce the lowest-density foam. Each polyhedral cell is made of numerous struts and films. On the other hand, high-density PFs are created by pressing the low-density samples. In order to show one of the important radiative properties of PF, Fig. 3 plots the thickness dependence of spectral infrared transmittance of the lowest-density PF BF301. In the case of thin PF (thickness of 1.9 mm), the infrared transmittance of BF301 is over 20 %. On the other hand, the infrared transmittance of thick PF (thickness of 9.3 mm) is less than 1 %. As in a vacuum, thermal radiation heat transfer is a dominant factor, it is thought that the thermal insulation performance of a low density, thin porous material indicates lower insulation performance in comparison with a thick one.

It is absolutely necessary to take into account the complicated inner microscopic structures as shown in Fig. 2 for estimating the effective thermal conductivity of such a foam. However, conventional estimation formulas for the thermal conductivity of porous materials are just empirical equations, and sometimes valid only for simple porous materials at atmospheric conditions [9]. It has been reported that the effective thermal conductivity of a porous material in a vacuum remains 10 times lower than that at atmospheric conditions (of the order of \(10^{-3}\,\mathrm{W} \cdot \mathrm{m}^{-1} \cdot \mathrm{K}^{-1})\) [10]. Therefore, an appropriate experimental method which can treat the heat transfer problem of a porous material in a high vacuum is required to determine the thermal conductivity of PF for space applications.

3 Effective Thermal-Conductivity Estimation

3.1 3D X-ray CT Image and Dodecahedron Model

As described in the previous section, the PF has a complex inner structure possibly expressed by reticular or cellular systems. Conventional estimation equations for the thermal conductivity of foam adopted several adjustable parameters in order to ensure agreement with limited available experimental data. Moreover, there have been few theoretical works concerning the influence of foam microscopic structures on the foam effective thermal conductivity. In order to account for the above-mentioned circumstances, we decided to construct a new geometrical model based on the actually observed 3D microscopic inner structure of the polyimide film for the effective thermal-conductivity estimation. We assume that this complicated inner structure of PF may considerably contribute to the total heat conduction and thermal radiation heat transfer.

To reflect the inner structure of PF for the effective thermal-conductivity estimation, the present study used an X-ray CT 3D image and dodecahedron model. Three-dimensional pictures of the PFs were constructed by synthesizing transfer images of the inner structure observed by X-ray CT at BL19B2 of SPring8 at the Japan Synchrotron Radiation Research Institute [11]. An example of the observed 3D image of polyimide foam BF301 is shown in Fig. 4. While the intertwining struts were successfully observed in the X-ray CT image, the film structures were not visible. This is because the spatial resolution of the X-ray CT (2.36 \(\upmu \)m) is larger than the thickness of the film (\({\sim }1\,\upmu \)m). For this reason, since the consideration of film parts is needed to accurately estimate the effective thermal conductivity, we assumed that the foams are constituted of an arrangement of polyhedron cells, and the cell shape resembles a dodecahedron in order to calculate the porosity of each type of polyimide foam.

Accordingly, the dodecahedron model was applied to calculate the volume fraction of the film parts of the cell [12]. The average strut size and cell diameter were directly determined from the X-ray images of PF and the film-part volume fraction was geometrically calculated through the dodecahedron model. Table 2 lists the porosity of the polyimide foam thus determined together with the actually measured individual density of specimens. In the process of this determination, the digital pixel data \((100\times 100\times 100)\) taken from 3D X-ray CT were used to distinguish the polyimide solid parts from the pores. Roughly speaking, white pixels in the bitmap data were allocated to indicate the solid parts and black pixels to the pores. More precisely, in order to incorporate both the 3D X-ray CT image and dodecahedron model for the estimation of the effective thermal conductivity, the threshold of the brightness value of each pixel was so chosen that the porosity determined with this process agrees with the porosity calculated by the dodecahedron model listed in Table 2.

3.2 Lattice Boltzmann Method (LBM)

In the present study, we applied the LBM for estimation of the effective thermal conductivity of polyimide foam. The LBM is a class of a simulation method for fluid motion by solving the evolution of a prescribed Boltzmann equation instead of by solving the Navier–Stokes equations. Due to its straightforward implementation of multiple inter-particle collisions and complex geometry boundary conditions, LBMs have been applied in various heat transfer problems, including heat flow through porous media, and thermal multiple phase flow [13].

There are two different heat transfer modes through polyimide foam in the vacuum condition; heat conduction through the solid parts and thermal radiation inside the pores. The LBM has an advantage in solving this kind of multiple heat transfer problem. In our calculation, the Bhatnagar–Gross–Krook (BGK) approximation [14], which is the simplest LBM, was adopted. The temperature evolution equation can be written as follows:

where r is the location vector, \(g_{\alpha }^\mathrm{eq}\) is the equilibrium distribution of variable evolution \(g_{\alpha }, t\) is the real time, and \(\delta _{t}\) is the time step. \(\tau \) is the dimensionless relaxation time, which is determined by the thermal conductivity of a solid grid or a pore grid, determined according to the 3D X-ray CT image explained in the previous section. The three-dimensional 15 speed (D3Q15) model was applied [15] for a cubic grid as illustrated in Fig. 5. In the solid grid, \(\tau \) is given as

In the pore grid, \(\tau \) is given as

where \(c\) is the pseudo-speed calculated from \(\delta _{x}/ \delta _{t}\) (\(\delta _{x}\) is grid size). For the grid assigned as the solid part, the thermal conductivity of polyimide resin \(\lambda _\mathrm{s}\) measured by the laser flash method at the Toray Research Center was substituted. The measured results for \(\lambda _\mathrm{s}\) are from (0.239 to 0.258) \(\mathrm{W} \cdot \mathrm{m}^{-1} \cdot \mathrm{K}^{-1}\) in the temperature range from 150 K to 370 K. For the grid assigned as the pore, the radiative conductivity \(\lambda _\mathrm{r}\) calculated by Eq. 4 was substituted [16]:

where \(d\) is the average diameter of a cell, \(\sigma \) is the Stefan Boltzmann constant, \(\varepsilon \) is the effective infrared emissivity of polyimide foam with \(\varepsilon = 0.8\) determined by the reflectivity measurement of a thick sample of BF301 with negligible infrared transmittance (we also assume \(\varepsilon \) is approximately constant in this temperature range). \(T\) is the absolute temperature of the grid.

The heat flux \(q\) was determined by the following equation:

After the temperature evolution equation was solved, the thermal conductivity was obtained from the following Fourier’s law to calculate the effective thermal conductivity \(\lambda _{\mathrm{eff}}\):

4 Effective Thermal-Conductivity Measurement

4.1 Periodic Heating Method

In the beginning, we employed the periodic heating method to measure the effective thermal conductivity of polyimide foam under vacuum conditions in the temperature range from 195 K to 373 K and the density range from 6.67 \(\mathrm{kg} \,\cdot \,\mathrm{m}^{-3}\) to 242.63 \(\mathrm{kg} \,\cdot \, \mathrm{m}^{-3}\) [4]. The periodic heating method can be applied to measure the thermal diffusivity with small temperature variation. When a sample is periodically heated by an attached heater on the sample, the temperature wave propagates in the sample with a phase lag \(\phi \). The phase lag \(\phi \) can be determined by the following equation:

where \(k\) is the wave number of the temperature wave, \(d\) is the sample thickness, \(f\) is the modulation frequency, and \(a\) is the thermal diffusivity. The thermal diffusivity can be determined from the slope of \(\phi \) against \(\sqrt{f}\). The thermal conductivity \(\lambda \) can be derived from the following equation:

where \(\rho \) is the density and \(C\) is the specific heat. The modulation frequency \(f\) was chosen from 0.004 Hz to 0.012 Hz so as to satisfy the condition of \(kd \approx 1\) in order to ensure attenuation of the temperature wave within the sample and to avoid reflection at the interface.

4.2 Guarded Hot-Plate Method

In a high-vacuum condition, the thermal radiation is the dominant mode of the heat transfer, especially in the case of the low-density porous material. Under such conditions, detection of the phase lag \(\phi \) by using the periodic heating method (described in the previous section) may become difficult, because the phase lag measurement technique relies on the assumption that the heat transfer mode is purely governed by heat conduction through a substance. Because of this reason, we recognized that a cross-check measurement with another technique, especially a steady-state method, is needed for the verification of the thermal-conductivity results obtained by periodic heating. The guarded hot-plate method was selected for the check measurement of thermal conductivity of BF301 whose density is the lowest in all types of PF in the present study.

The thermal conductivity, \(\lambda \), was calculated from the power supplied, \(Q\), the mean difference in temperature between two plates, \(T_{\mathrm{h}} - T_{\mathrm{c}}\), the cross-sectional area of the main plate \(A\), and the mean thickness of the specimens \(l\), using the following one-dimensional heat conduction equation for infinite parallel plates in the steady-state condition:

Figure 6 shows a newly developed guarded hot-plate apparatus to measure the effective thermal conductivity of polyimide foam in a vacuum. The degree of vacuum in the chamber was maintained under \(2.7\times 10^{-4}\) Pa at any time. The inner wall of the chamber was cooled with liquid nitrogen down to 100 K. All parts of the guarded hot-plate which consists of two identical polyimide specimens, a main heater, a guard heater, and two plate heaters are suspended in the chamber. The size of the specimens was 260 mm \(\times \) 312 mm with a thickness of approximately 10 mm; therefore, the infrared transmittance across the specimens was less than 1 % as already shown in Fig. 3. The gap between the main heater and the guard heater was 1 mm. By using two independent temperature controllers, the temperature difference between the guard and the main heaters was continuously maintained within 0.1 K in order to prevent heat transfer between them. The plate heaters provide appropriate heat flux to keep the temperature difference, \(\Delta T=T_{\mathrm{h}} - T_{\mathrm{c}}\), between the main heater and the plate heater at about 10 K. For the calculation of the thermal conductivity using Eq. 9, we employed the average temperature of specimens 1 and 2 listed in Table 3.

High-thermal-conductivity aluminum tape was used in order to maintain adequate thermal contact between the thermocouples and the heaters. Three sets of thermocouples were attached on each plate heater, on the main heater, and on the guard heater. All thermocouples are K-type with a diameter of 100 \(\upmu \)m. It should be mentioned here that we carefully installed all thermocouples so as to minimize the heat leak from the thermocouples by taping them on both main and guard heaters which are maintained within a temperature difference of 0.1 K. The measurements of the effective thermal conductivity were performed in the temperature range from 160 K to 370 K.

The measured density and mean thickness of the specimen are shown in Table 3. The mean thickness was calculated from nine different sampling points. It should be mentioned here that densities listed in Table 1 are catalog nominal values reported from the supplier. For the reliable evaluation of the porosity and thermal conductivity of these low-density insulation materials, we need to measure the densities of these samples one by one because they are not uniform. Consequently, values in Tables 1, 2, and 3 are different even though the sample is listed under the same name. However, in the case of the lowest-density sample BF301, the differences between these values are within some 20 %, and we are able to use the present experimental results by measuring the real density before application.

The combined standard relative uncertainty for the thermal conductivity can be represented by the following equation in accordance with the symbol definitions by guide to the expression of uncertainty in measurement (GUM) [17]:

By taking into account all source of individual uncertainties, the overall uncertainty in the effective thermal conductivity is estimated to be 7.8 % (\(k = 2\)). For further confirmation of the above-mentioned uncertainty and validity of the present guarded hot-plate apparatus, the effective thermal conductivity of polyimide form BF301 was measured under atmospheric pressure. For this purpose, we employed the heat flow meter method developed at Nichias Corporation which has been calibrated by the standard reference material (NIST SRM 1450c; glass fiberboard with maximum uncertainty of 1.6 %) [18] in the temperature range from 303 K to 323 K. Figure 7 compares the experimental results of the effective thermal conductivity of BF301 measured by the heat flow meter and the present guarded hot-plate method under atmospheric pressure. At 303 K, both experimental results agree well with 5.9 %. Consequently, it can be concluded that the uncertainty of the present thermal-conductivity measurement apparatus by the guarded hot-plate method is confirmed.

5 Results and Discussion

5.1 Temperature Dependence of Effective Thermal Conductivity of BF301

In Fig. 8, the temperature dependence of the effective thermal conductivity of BF301 determined by the periodic heating and the guarded hot-plate experiments are compared with the estimated values using the LBM. As can be seen from this figure, the effective thermal conductivity of high-porosity BF301 shows a notable temperature dependence. This is because the thermal radiation is the dominant heat transfer mode in the case of a highly porous material, and the effect of thermal radiation heat transfer becomes more significant at higher temperatures as thermal radiation is directly proportional to the fourth power of the absolute temperature. Values calculated by the LBM exhibit the same temperature dependence as those measured by the periodic heating method. However, in terms of the absolute effective thermal-conductivity value, the experimental results by periodic heating indicate a value of about 0.0017 \(\mathrm{W} \,\cdot \, \mathrm{m}^{-1} \cdot \mathrm{K}^{-1}\) systematically higher on average than the LBM estimation. On the contrary, the experimental results obtained by the guarded hot-plate method agree very well with the LBM calculation not only in their temperature dependence but also in their absolute values. At low temperatures below 200 K, both effective thermal-conductivity values measured by the guarded hot-plate and that calculated by the LBM indicate values on the order of \(10^{-4}\,\mathrm{W} \cdot \mathrm{m}^{-1} \cdot \mathrm{K}^{-1}\). At the lowest temperature of 165 K, the measured effective thermal conductivity by the periodic heating shows a value approximately four times larger than that by the guarded hot-plate. The major reason for this serious difference is caused by radiation heat transfer, since the thickness of the sample used in the periodic heating method was about 2 mm, and in that case, the infrared transmittance exceeds by more than 20 % that in almost all wavelength regions (Fig. 3). In the case of a thick foam, the thermal radiation is absorbed by solid parts of PF (struts and films) and is re-radiated from the solid parts to other parts. On the contrary in the case of a thin foam, the thermal radiation directly reaches the thermocouples so that the detected phase lag turns out to be small. That is why the effective thermal-conductivity values measured by the periodic heating method show apparently larger values than those by the guarded hot-plate method and LBM. This leads to the conclusion that the guarded hot-plate experiments and LBM estimations are both appropriate tools for the evaluation of the effective thermal conductivity in a wide range of temperatures and especially in a vacuum.

5.2 Density Dependence of Effective Thermal Conductivity of Polyimide Foam in a Vacuum

Figure 9 displays the density dependence of the effective thermal conductivity of four PFs listed in Table 2 at 370 K in a vacuum. The experimental results obtained by periodic heating and the guarded hot-plate are compared with two different LBM calculations in consideration of with and without film parts. By comparing the data in Figs. 7 and 9, the effective thermal conductivity of the present PFs in a vacuum is a few tenths part of that in the atmosphere. It seems appropriate to judge from Fig. 9 that a local minimum value of the effective thermal conductivity exists. For lower density PF in which the thermal radiation is the dominant heat transfer mode, the effective thermal conductivity becomes higher. Instead, for higher density PF in which the heat conduction turns out to be the dominant heat transfer mode, the effective thermal conductivity becomes also higher. Therefore, a local minimum point can be observed in the density dependence of the effective thermal conductivity of porous materials in a vacuum. The calculated results by the LBM considering the film parts in the model clearly indicate a minimum value at a density of around 50 \(\mathrm{kg} \,\cdot \, \mathrm{m}^{-3}\). Except for the result at the lowest-density BF301 measured by the periodic heating method, the agreement between the experimentally obtained effective thermal conductivity data and the calculated results by the LBM with film consideration is quite adequate for practical application within the average deviation of 10 %. Due to the fact that the infrared transmittance for higher density PFs indicates less than a few percent at most, by excluding the application to the lowest-density foam, the results measured by the periodic heating method can be evaluated within an uncertainty of 15 % including the uncertainties in density and heat capacity. The present study leads to the conclusion that the LBM calculation using the X-ray CT image and the dodecahedron model is an effective tool for estimation of the effective thermal conductivity of porous materials having a random complicated inner structure.

Density dependence of the effective thermal conductivity of four polyimide foams listed in Table 2 at 370 K in a vacuum. The experimental results obtained by the periodic heating and the guarded hot-plate are compared with two different LBM calculations in consideration of with and without film parts

6 Conclusion

Effective thermal-conductivity measurements were carried out by both the periodic heating method and the guarded hot-plate method in the temperature range from 160 K to 370 K and the density range from 6.67 \(\mathrm{kg} \cdot \mathrm{m}^{-3}\) to 242.63 \(\mathrm{kg} \cdot \mathrm{m}^{-3}\) in a high vacuum and under atmospheric pressure. For confirmation of the validity of the present guarded hot-plate apparatus under atmospheric pressure, the effective thermal conductivity of the lowest-density PF was measured with the aid of the heat flow meter apparatus calibrated by a standard reference material (NIST SRM 1450c) in the temperature range from 303 K to 323 K. In the case of the lowest-density PF, we found that the measured effective thermal conductivity by periodic heating showed a value approximately four times larger than that by the guarded hot-plate. The major reason for this difference is caused by radiation heat transfer resulting from the high infrared transmittance of the lowest-density thin PF. In order to cross-check the present experimental results, we directly calculated the temperature and density dependences of the effective thermal conductivity of PF by means of the LBM based on a dodecahedron inner microscopic complex structure model which reflects a real 3D X-ray CT image of PF. The guarded hot-plate apparatus and LBM calculations are both appropriate tools for the evaluation of the effective thermal conductivity of PF in the wide ranges of temperature and density in a vacuum. Except for the extremely low-density PF, the periodic heating method is also a useful experimental tool for the present purpose.

The present study leads to the conclusion that the low density and low-thermal conductivity PF BF301 and BP101 will be suitable thermal insulation materials for outer space applications.

References

S. Okazaki, M. Murakami, H. Kawasaki, T. Yabe, Y. Kanamori, “Experimental Study of Influence of Processing on MLI Performance for Space Use,” in 38th International Conference on Environmental Systems, SAE-2008-01-2067, San Francisco, CA (2008)

T. Ohmura, M. Tsuboi, in Proceedings of the 21st Japan Symposium on Thermophysical Properties, Nagoya, Japan (2000), p. 147

J. Paek, B. Kang, S. Kim, J. Hyun, Int. J. Thermophys. 21, 453 (2000)

Y. Hiasa, H. Nagano, A. Ohnishi, Y. Nagasaka, in Proceedings of the 8th Asian Thermophysical Properties Conference, No. 152, Fukuoka, Japan (2007)

M. Wang, N. Pan, Int. J. Heat Mass Transf. 51, 1325 (2008)

M. Wang, N. Pan, Mater. Sci. Eng. R 63, 1 (2008)

M. Wang, J. Wang, N. Pang, S. Chen, Phys. Rev. E 15, 036702 (2007)

UPILEX-FOAM DATA SHEET, UBE Industries, Ltd. (2000)

D. Kunii, J. Smith, AIChE J. 6, 71 (1960)

M.K. Williams, E.S. Weiser, J.E. Fesmire, B.W. Grimsley, T.M. Smith, J.R. Brenner, G.L. Nelson, Polym. Adv. Technol. 16, 167 (2005)

Y. Mizutani, T. Sugihara, S. Tachikawa, A. Ohnishi, K. Kajiwara, Y. Nagasaka, in Proc. 30th Japan Symposium on Thermophysical Properties, Yonezawa, Japan (2009), p. 262

E. Placido, M. Arduini-Schuster, J. Kuhn, Infrared Phys. Technol. 46, 219 (2005)

M. Wang, J. Wang, N. Pan, S. Chen, J. He, J. Phys. D 40, 260 (2007)

J. Wang, M. Wang, Z. Li, Int. J. Therm. Sci. 46, 228 (2007)

X. Hong, W. Di, S. Yuhe, Res. J. Appl. Sci. Eng. Technol. 6, 2520 (2013)

L. Gibson, M. Ashby, Cellular Solids: Structure & Properties (Pergamon Press, Oxford, 1988)

BIPM, IEC, IFCC, ISO, IUPAC, IUPAP, OIML, “Guide to the Expression of Uncertainty in Measurement” (International Organization for Standardization, Geneva, 1993)

R.R. Zarr, Standard Reference Materials: Glass Fiberboard, SRM 1450c, for Thermal Resistance from 280 K to 340 K. NIST Special Publication 260–130 (National Institute of Standards and Technology, U.S. Government Printing Office, Washington, DC, 1997)

Acknowledgments

The authors acknowledge Dr. Ohnishi (Institute of Space and Astronautical Science) for the initial concept on the present research and Messrs. Yasuhiro Hiasa, Takashi Sugihara, and Yuki Mizutani, students of Keio University at that time, for their assistance in carrying out experiments and calculations. The authors also wish to thank UBE Industries, Ltd. for supplying the polyimide foams. The work described in this paper was partially supported under a Grant-in-Aid for Scientific Research (S) (No. 24226006) from the Japan Society for the Promotion of Science (JSPS).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Takagi, R., Tachikawa, S., Ohmura, T. et al. Measurement and Estimation of High-Vacuum Effective Thermal Conductivity of Polyimide Foam in the Temperature Range from 160 K to 370 K for Outer Space Applications. Int J Thermophys 35, 277–289 (2014). https://doi.org/10.1007/s10765-014-1605-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10765-014-1605-5