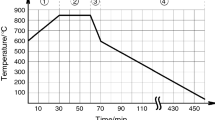

The composition and a method of production are proposed for high-porosity materials in low-temperature foaming of liquid glass and ash-slag material from burning of combustible shales used as fill and consumable additives. It is shown that keramzit based on liquid glass must be cooled at the rate 60 K/min, because a porous material with high structural quality factor and with high FeO content is formed at this cooling rate.

Similar content being viewed by others

References

A. I. Kudyakov, N. A. Svergunova, and M. Yu. Ivanov, Granular Insulating Material Based on a Modified Liquid Glass Composition [in Russian], Izd. TGASU, Tomsk (2010).

E. S. Abdrakhimova and V. Z. Abdrakhimov, “Highly porous thermal insulating material based on liquid glass,” Fiz. Khim. Stekla, 43(2), 222 – 230 (2017).

V. Z. Abdrakhimov, “Study of the phase composition of thermal-insulation materials based on solid salt slags and liquid glass,” Izv. Vysh. Ucheb. Zaved., Stoitel’stvo, No. 11 – 12, 33 – 39 (2008).

V. F. Gillebrand and G. A. Lendel, A Practical Guide to Inorganic Analysis [in Russian], Khimiya, Moscow (1965).

E. S. Abdrakhimova, V. Z. Abdrakhimov, and A. K. Kairakbaev, The Use of Wastes from the Fuel and Energy Complex in the Production of Thermal-Insulation Materials Based on Liquid Glass Compositions [in Russian], Kazakhsk.-Rus. Mezhdunar. Universitet, Aktobe (2016).

V. Z. Abdrakhimov, “Composition for the production of waterresistant porous filler, RF Pat. 2478084, C2 SB 14B 14/24,” Byull. Izobr. Polezn. Modeli, No. 9 (2013), publ. March 27, 2013.

V. Z. Abdrakhimov, V. K. Semenychev, V. A. Kulikov, and E. S. Abdrakhimova, “Method of producing porous aggregate, Pat. 2426710, C1 C04B 38/06, 33/132,” Byull. Izobr. Polezn. Modeli, No. 23 (2011), publ. August 20, 2011.

V. F. Pavlov, Physical and Chemical Principles of Firing Building Ceramic Articles [in Russian], Stroiizdat, Moscow (1977).

E. S. Abdrakhimova and V. Z. Abdrakhimov, “Structural transformations of iron compounds in clayey materials according to Mössbauer spectroscopy data,” Zh. Fiz. Khim., 80(7), 1 – 8 (2011).

G. V. Kukolev, Silicon Chemistry and Physical Chemistry of Silicates [in Russian], Vyssh. Shkola, Moscow (1966).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Steklo i Keramika, No. 9, pp. 40 – 44, September, 2018.

Rights and permissions

About this article

Cite this article

Abdrakhimova, E.S. Optimal Cooling Rate of Porous Fill Based on Liquid-Glass Compositions. Glass Ceram 75, 366–369 (2019). https://doi.org/10.1007/s10717-019-00086-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10717-019-00086-6