Abstract

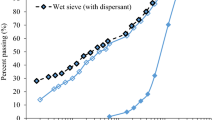

The effect of microfabric on the mechanical behaviour of clays has been explored previously based on the response of dispersed and flocculated microfabrics only. However, the natural clays often have the geometric arrangement of particles between these two extreme cases which can be termed as intermediate microfabric. This paper explores the formation of intermediate microfabric of kaolin clay and its impact on soil’s consolidation behaviour by performing self-weight consolidation, slurry consolidation and 1-D consolidation tests. The effect of calgon content (dispersing agent) on geometric arrangement of the particles has been evaluated through cluster size distribution by performing double hydrometer tests. Then these clay slurries have been used to perform the AFM (Atomic Force Microscopy) test to obtain the variation in average angle of particle orientation with respect to the calgon content present in the slurry. AFM technique provides 3D image of the clay sample and 2D image with Z-information with the potential of measuring intermediate microfabric of clayey soil quantitatively including dispersed and flocculated microfabrics. Other traditional techniques such as SEM, TEM & XRD are limited to only qualitative analysis of soil’s microfabric, thus, having no capability to measure intermediate microfabric of clay. A methodology of preparing bulk specimens of clay with intermediate microfabric has been developed using slurry consolidation technique; and then these specimens have been consolidated under 1-D loading to evaluate the effect of intermediate microfabric on compressibility and permeability of clay. In this study, all the experiments reports that the dispersed type geometric arrangement increases with the increase in calgon content in soil up to 2 % and then the reverse behaviour is observed at 3 %; which may depend on the required amount of sodium cations to neutralize the negatively charged faces of the clay platelets present in the slurry.

Similar content being viewed by others

References

ASTM (1999) Standard test method for dispersive characteristics of clay soil by double hydrometer, D4221-99. West Conshohocken, PA

Bai X, Smart P (1997) Change in microstructure of kaolin in consolidation and undrained shear. Geotechnique 47(3):1009–1017

Barden L, Sides G (1971) Sample disturbance in the investigation of clay structure. Geotechnique 21(3):211–222

Bolt GT (1956) Physicochemical analysis of the compressibility of pure clays. Geotechnique 6(2):86–93

Carroll D (1970) Clay minerals: a guide to their X-ray identification. The Geological Society of America, INC, Colorado

Carty WM (1999) The colloidal nature of kaolinite. Am Ceram Soc Bull 77(8):72–76

Chen J, Anandarajah A, Inyang H (2000) Pore fluid properties and compressibility of kaolinite. J Geotech Geo-environ Eng 126(9):798–807

Collins K, McGown A (1974) The form and function of microfabric features in a variety of natural soils. Geotechnique 24(2):223–254

McConnachie I (1974) Fabric changes in consolidated kaolin. Geotechnique 24(4):207–222

Mitchell JK, Soga K (2005) Fundamentals of soil behaviour, 3rd edn. Wiley, Hoboken

Moore CA, Mitchell JK (1974) Electromagnetic forces and shear strength. Geotechnique 24(4):627–636

Morgenstern NR, Tchalenko JS (1967) Microscopic structures in kaolin subjected to direct shear. Geotechnique 17:309–328

Nagaraj TS (1964) Soil structure and strength characteristics of compacted clay. Geotechnique 14(2):103–114

Penumadu D (1996) Evaluating clay microfabric using scanning electron microcopy and digital information processing. Transp Res Rec 1526:112–120

Penumadu D, Skandarajah A, Chameau JL (1998) Strain-rate effects in pressuremeter testing using a cuboidal shear device: experiments and modeling. Can Geotech J 35:27–42

Prashant A, Penumadu D (2007) Effect of microfabric on mechanical behaviour of kaolin clay using cubical true triaxial testing. J Geotech Geo-environ Eng 133(4):433–444

Romero E, Simms PH (2008) Microstructure investigation in unsaturated soils: a review with special attention to contribution of mercury intrusion porosimetry and environmental scanning electron microscopy. J Geotech Geol Eng 26(6):705–727

Sachan A (2007) Variation in geometric arrangement of particles in kaolinite clay due to shear deformation using SEM technique. Curr Sci 93(4):515–522

Sachan A, Penumadu D (2007a) Effect of microfabric on shear behaviour of kaolin clay. J Geotech Geo-environ Eng ASCE 133(3):306–318

Sachan A, Penumadu D (2007b) Identification of microfabric of kaolinite clay mineral using X-ray diffraction technique. J Geotech Geol Eng 25(6):603–616

Sachan A (2008) Use of atomic force microscopy (AFM) for microfabric study of cohesive soils. J Microsc 232(2):422–431

Sachan A, Mehrotra V (2008) Evaluation of microfabric of clay using atomic force microscopy. Curr Sci 95(12):1699–1706

Sridharan A, Rao GV (1973) Mechanisms controlling volume change of saturated clays. Geotechnique 23(3):359–382

Sridharan A, Rao S, Rao G (1971) Shear strength characteristics of saturated montmorillonite and kaolin clays. Soils Found 11:1–22

Van Olphen H (1964) Internal mutual flocculation in clay suspensions. J Colloid Interface Sci 19:313–319

Van Olphen H (1977) An introduction to clay colloid chemistry, 2nd edn. Wiley-Blackwell, Hoboken

Yimsiri S, Soga K (2000) Micromechanics-based stress-strain behaviour of soils at small strains. Geotechnique 50(5):559–571

Yong RA, Hewat AW (1988) Verification of the triclinic crystal structure of kaolinite. Clay Clay Miner 36(3):225–232

Acknowledgments

Financial Support from Department of Science and Technology (DST) India through grants SR/S3/MERC/12/2006 is gratefully acknowledged. Any opinions, findings, and conclusions or recommendations expressed in this material are those of authors and do not necessarily reflect the views of DST.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sachan, A., Vikash, G. & Prashant, A. Development of Intermediate Microfabric in Kaolin Clay and Its Consolidation Behaviour. Geotech Geol Eng 31, 23–34 (2013). https://doi.org/10.1007/s10706-012-9557-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-012-9557-7