Abstract

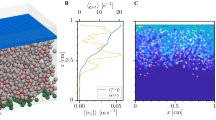

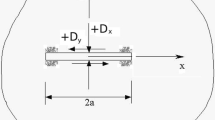

Mechanical behavior of two-dimensional microstructures containing circular pores were simulated under uniaxial and biaxial loading using the finite element method. Resulting stress distributions were combined with classical fracture mechanics to investigate fracture behavior of brittle porous materials assuming that randomly oriented cracks are present along pore surfaces. Multiple crack orientations were found to introduce a variability in Weibull modulus even for the same set of microstructures containing equal number and size of cracks. Also, the variability increases with increasing crack size to pore size ratio. Under uniaxial loading, angular distribution of fracture origin widens with increasing porosity.

Similar content being viewed by others

References

Ashby M (2013) Designing architectured materials. Scr Mater 68(1):4–7

Atkinson A, Selçuk A (1997) Mechanical properties of ceramic materials for solid oxide fuel cells. In: Stimming U, Singhal SC, Tagawa H, Lehnert W (eds) Proceedings of the 5th international symposium on solid oxide fuel cells, Electrochemical society proceedings, pp 671–680

Atkinson A, Bastid P, Liu Q (2007) Mechanical properties of magnesia-spinel composites. J Am Ceram Soc 90(8):2489–2496

Bertolotti RL, Fulrath RM (1967) Effect of micromechanical stress concentrations on strength of porous glass. J Am Ceram Soc 50(11):558–562

Biswas DR, Fulrath RM (1977) Mechanical properties of porous PNZT polycrystalline ceramics. In: Bradt RC, Hasselman DPH, Lange FF (eds) Fracture mechanics of ceramics, vol 4. Crack growth and microstructure, Plenum Press, pp 933–944

Biswas DR, Fulrath RM (1980) Strength of porous polycrystalline ceramics. Trans J Br Ceram Soc 79(1):1

Brechet Y, Embury J (2013) Architectured materials: expanding materials space. Scr Mater 68(1):1–3

Chen PY, Lin AYM, Lin YS, Seki Y, Stokes AG, Peyras J, Olevsky EA, Meyers MA, McKittrick J (2008) Structure and mechanical properties of selected biological materials. J Mech Behav Biomed Mater 1(3):208–226

Davis ME (2002) Ordered porous materials for emerging applications. Nature 417(6891):813–821

Evans AG, Biswas DR, Fulrath RM (1979) Some effects of cavities on the fracture of ceramics: II, spherical cavities. J Am Ceram Soc 62(1–2):101–106

Fallet A, Lhuissier P, Salvo L, Martin C, Wiegmann A, Kabel M (2013) Multi- functional optimization of random hollow sphere stackings. Scr Mater 68(1):35–38

Fan X, Case ED, Ren F, Shu Y, Baumann MJ (2012a) Part I: porosity dependence of the Weibull modulus for hydroxyapatite and other brittle materials. J Mech Behav Biomed Mater 8:21–36

Fan X, Case ED, Ren F, Shu Y, Baumann MJ (2012b) Part II: fracture strength and elastic modulus as a function of porosity for hydroxyapatite and other brittle materials. J Mech Behav Biomed Mater 8:99–110

Frandsen HL, Ramos T, Faes A, Pihlatie M, Brodersen K (2012) Optimization of the strength of SOFC anode supports. J Eur Ceram Soc 32(5):1041–1052

Gerrienne P, Gensel PG, Strullu-Derrien C, Lardeux H, Steemans P, Prestianni C (2011) A simple type of wood in two early devonian plants. Science 333(6044):837–837

Giannini M, Soares CJ, de Carvalho RM (2004) Ultimate tensile strength of tooth structures. Dent Mater 20(4):322–329

Hasselman DPH, Fulrath RM (1967) Micromechanical stress concentrations in two-phase brittle-matrix ceramic composites. J Am Ceram Soc 50(8):399–404

Kachanov M (1993) Elastic solids with many cracks and related problems. Adv Appl Mech 30:259–445

Keleş Ö, García RE, Bowman KJ (2013a) Deviations from Weibull statistics in brittle porous materials. Acta Mater 61(19):7207–7215

Keleş Ö, García RE, Bowman KJ (2013b) Stochastic failure of isotropic, brittle materials with uniform porosity. Acta Mater 61(8):2853–2862

Kishimoto A, Koumoto K, Yanagida H, Nameki M (1991) Microstructure dependence of mechanical and dielectric strengths—i. porosity. Eng Fract Mech 40(4):927–930

Krstic VD (2006) Effect of microstructure on fracture of brittle materials: unified approach. Theor Appl Fract Mech 45(3):212–226

Lai W, Erdonmez CK, Marinis TF, Bjune CK, Dudney NJ, Xu F, Wartena R, Chiang YM (2010) Ultrahigh-energy-density microbatteries enabled by new electrode architecture and micropackaging design. Adv Mater 22(20):E139–E144

Launey ME, Buehler MJ, Ritchie RO (2010) On the mechanistic origins of toughness in bone. Annu Rev Mater Res 40:25–53

Li Y, Wu D, Zhang J, Chang L, Wu D, Fang Z, Shi Y (2000) Measurement and statistics of single pellet mechanical strength of differently shaped catalysts. Powder Technol 113(1):176–184

Liu DM (1996) Control of pore geometry on influencing the mechanical property of porous hydroxyapatite bioceramic. J Mater Sci Lett 15(5):419–421

Liu X, Martin CL, Delette G, Bouvard D (2010) Elasticity and strength of partially sintered ceramics. J Mech Phys Solids 58(6):829–842

Lopes MA, Monteiro FJ, Santos JD (1999) Glass-reinforced hydroxyapatite composites: secondary phase proportions and densification effects on biaxial bending strength. J Biomed Mater Res 48(5):734–740

Meyers MA, Chen PY, Lin AYM, Seki Y (2008) Biological materials: structure and mechanical properties. Prog Mater Sci 53(1):1–206

Miserez A, Weaver JC, Pedersen PB, Schneeberk T, Hanlon RT, Kisailus D, Birkedal H (2009) Microstructural and biochemical characterization of the nanoporous sucker rings from dosidicus gigas. Adv Mater 21(4):401–406

Murray MGS, Wang J, Ponton CB, Marquis PM (1995) An improvement in processing of hydroxyapatite ceramics. J Mater Sci 30(12):3061–3074

Nanjangud SC, Brezny R, Green DJ (1995) Strength and young’s modulus behavior of a partially sintered porous alumina. J Am Ceram Soc 78(1):266–268

Pissenberger A, Gritzner G (1995) Preparation and properties of niobia-and tantala-doped orthorhombic zirconia. J Mater Sci Lett 14(22):1580–1582

Radovic M, Lara-Curzio E (2004) Mechanical properties of tape cast nickel-based anode materials for solid oxide fuel cells before and after reduction in hydrogen. Acta Mater 52(20):5747–5756

Rice RW (1998) Porosity of ceramics. CRC Press, Boca Raton, FL

Rossoll A, Mortensen A (2013) On the load-bearing efficiency of open-cell foams: a comparison of two architectures related to two processes. Scr Mater 68(1):44–49

Ruys AJ, Wei M, Sorrell CC, Dickson MR, Brandwood A, Milthorpe BK (1995) Sintering effects on the strength of hydroxyapatite. Biomaterials 16(5):409–415

Shah RC (1976) Mechanics of crack growth. ASTM STP 590:429–459

Wallace JS (1978) Effect of mechanical discontinuities on the strength of polycrystalline aluminum oxide. Master’s thesis, University of California, Berkeley

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Keleş, Ö., García, R.E. & Bowman, K.J. Pore–crack orientation effects on fracture behavior of brittle porous materials. Int J Fract 187, 293–299 (2014). https://doi.org/10.1007/s10704-014-9934-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-014-9934-8