Abstract

In this study, several two-parameter- concepts are analyzed experimentally and numerically with respect to their capability of characterizing in-plane and out-of-plane crack tip constraint effects. Different approaches utilizing the second term T stress of the linear-elastic crack tip stress field, a higher term A 2 of the power-law hardening crack tip stress field, a hydrostatic correction term Q for a reference stress field or the local triaxiality parameter h are compared. Experimental results for a pressure vessel steel 22NiMoCr3-7 are investigated by means of the different approaches regarding their capability of constraint characterization for enhanced transferability. Theoretical aspects are investigated in a modified boundary layer analysis and in three-dimensional nonlinear elastic-plastic finite element analyses of the specimens. It is found that, with respect to their capability of quantifying combined in-plane and out-of-plane constraint effects, the investigated concepts differ significantly.

Similar content being viewed by others

Abbreviations

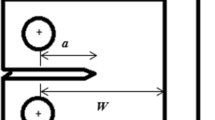

- a :

-

Crack depth

- A i :

-

Intensities of the first three terms of the power-law hardening crack tip stress field

- B :

-

Specimen thickness or crack front length

- E :

-

Young’s modulus

- \(f^{(k)}_{ij}\) :

-

Circumferential stress distribution of the linear-elastic crack tip stress field

- h :

-

Stress triaxiality parameter

- I :

-

Constant of the HRR-singularity

- J :

-

J-integral

- J c :

-

Fracture toughness

- J elastic :

-

Elastic part of the global J-integral

- J 2 :

-

Second invariant of the Cauchy stress tensor

- K :

-

Stress intensity factor

- K I :

-

Mode-I stress intensity factor

- K Ic :

-

Fracture toughness

- K J :

-

Stress intensity factor determined from J-integral

- \(\dot{K}\) :

-

Loading rate

- K Jc :

-

Fracture toughness

- l :

-

Reference length scale parameter

- n :

-

Hardening exponent in the Ramberg–Osgood constitutive equation

- Q :

-

Q-parameter, additional hydrostatic stress superimposed on a reference field

- Q BLA :

-

Q-parameter determined from a FE small scale yielding reference field

- Q HRR :

-

Q-parameter determined from the HRR-singularity as reference field

- Q t :

-

Q-parameter determined from the out-of-plane stress component

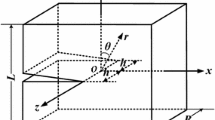

- r :

-

Radius of crack front polar reference system

- s i :

-

Exponents in the power-series expansion of the power-law hardening crack tip stress field

- T :

-

Actual testing temperature

- T 0 :

-

Master curve reference temperature

- T stress :

-

Intensity of the second term of the linear-elastic crack tip stress field

- w :

-

Specimen nominal width

- x i :

-

Cartesian coordinates

- z :

-

Thickness coordinate of crack front polar reference system

- α :

-

Parameter in the Ramberg–Osgood constitutive equation

- δ ij :

-

Components of the unit tensor

- ε ij :

-

Components of the linearized strain tensor

- ε 0 :

-

Strain parameter in the Ramberg–Osgood constitutive equation

- η :

-

Plastic correction factor

- ν :

-

Poisson’s ratio

- φ :

-

Angle of crack front polar reference system

- σ ij :

-

Components of the Cauchy stress tensor

- σ′ ij :

-

Deviatoric components of the Cauchy stress tensor

- \(\tilde{\sigma}^{(k)}_{ij}\) :

-

Circumferential stress distribution of the power-law hardening crack tip stress field

- \({\sigma^{\rm ref}_{ij}}\) :

-

Reference crack front stress field

- σ e :

-

v. Mises equivalent stress

- σ I :

-

Maximum principal Cauchy stress

- σ 0 :

-

Yield stress

References

ASTM Standard E1921-02 (2002) Standard test method for determination of reference temperature T 0 for ferritic steels in the transition range. American Society for Testing and Materials, West Conshohocken, PA

Brocks W and Schmitt W (1995). The second parameter in J–R curves: constraint or triaxiality?. In: Kirk, M and Bakker, A (eds) Constraint effects in fracture—theory and applications, vol 2, ASTM STP 1244, pp 209–231. American Society for Testing and Materials, West Conshohocken, PA,

Chao YJ, Yang S and Sutton MA (1994). On the fracture of solids characterized by one or two parameters: theory and practice. J Mech Phys Solids 42: 629–647

Chao YJ, Zhu XK, Kim Y, Lar PS, Pechersky MJ and Morgan MJ (2004). Characterization of crack-tip field and constraint for bending specimens under large-scale yielding. Int J Fract 127: 283–302

Du ZZ and Hancock JW (1991). The effect of non-singular stresses on crack-tip constraint. J Mech Phys Solids 39: 555–567

Henry BS and Luxmoore AR (1997). The stress triaxiality constraint and the Q-value as ductile fracture parameter. Eng Fract Mech 57: 375–390

Hohe J, Tanguy B, Friedmann V, Stöckl H, Böhme W, Varfolomeyeva V, Hebel J, Burdack M, Fehrenbach C, Schüler J, Sguaizer Y, Siegele D (2004) Kritische Überprüfung des Mastercurve-Ansatzes im Hinblick auf die Anwendung bei deutschen Kernkraftwerken, Report No. S8/2004. Fraunhofer Institut für Werkstoffmechanik, Freiburg

Hohe J, Hebel J, Friedmann V and Siegele D (2007). Probabilistic failure assessment of ferritic steels using the master curve approach including constraint effects. Eng Fract Mech 74: 1274–1292

Hutchinson JW (1968). Singular behavior at the end of a tensile crack in a hardening material. J Mech Phys Solids 16: 13–31

Kfouri AP (1986). Some evaluation of the elastic T-term using Eshelbys method. Int J Fract 30: 301–315

Kim Y, Zhu XK and Chao YJ (2001). Quantification of constraint on elastic-plastic 3D crack front by the J–A 2 three-term solution. Eng Fract Mech 68: 895–914

Kim Y, Chao YJ and Zhu XK (2003). Effect of specimen size and crack depth on 3D crack-front constraint for SENB specimens. Int J Solids Struct 40: 6267–6284

Nakamura T and Parks DM (1992). Determination of elastic T-stress along three-dimensional crack fronts using an interaction integral. Int J Solids Struct 29: 1596–1611

Nikishkov GP (1995). An algorithm and a computer program for the three-term asymptotic expansion of elastic-plastic crack tip stress and displacement fields. Eng Fract Mech 50: 65–83

O’Dowd NP (1995). Applications of two parameter approaches in elastic-plastic fracture mechanics. Eng Fract Mech 52: 445–465

O’Dowd NP and Shih CF (1991). Family of crack-tip fields characterized by a triaxiality parameter—I. Structure of fields. J Mech Phys Solids 39: 989–1015

Rice JR (1968). A path independent integral and the approximate analysis of strain concentration by notches and cracks. J Appl Mech 35: 379–386

Rice JR and Rosengren GF (1968). Plane strain deformation near a crack tip in a power-law hardening material. J Mech Phys Solids 16: 1–12

Wallin K (1991). Statistical modeling of fracture in the ductile-to-brittle transition range. In: Blauel, JG and Schwalbe, KH (eds) Defect assessment in components, fundamentals and applications, pp 415–445. Mechanical Engineering Publications, London

Williams ML (1957). On the stress distribution at the base of a stationary crack. J Appl Mech 24: 109–114

Yuan H and Brocks W (1998). Quantification of constraint effects in elastic-plastic crack front fields. J Mech Phys Solids 46: 219–241

Yang S, Chao YJ and Sutton MA (1993). Higher order asymptotic crack tip fields in a power-law hardening material. Eng Fract Mech 45: 1–20

Zhu XK and Leis BN (2006). Bending modified J–Q theory and crack-tip constraint quantification. Int J Fract 141: 115–134

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hebel, J., Hohe, J., Friedmann, V. et al. Experimental and numerical analysis of in-plane and out-of-plane crack tip constraint characterization by secondary fracture parameters. Int J Fract 146, 173–188 (2007). https://doi.org/10.1007/s10704-007-9160-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-007-9160-8