Abstract

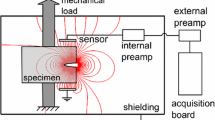

Two effects, magnetic and electric emission, have been observed and used in fracture tests to detect and analyse onset and progress of plastic deformation and fracture. While magnetic emission (ME) occurs only in ferromagnetic materials, electric emission (EE) can be found with any material, metals as well as plastics, ceramics, glass, and others. In ferromagnetic materials the two effects supplement each other. In steel, for example, electric emission is produced by plastic deformation but not by fracture; magnetic emission, on the other hand, is produced by fracture but not by plastic deformation. This paper describes the effects, demonstrates their application in Charpy tests, and shows how to derive fracture parameters, for instance the instants of the onset of plastic deformation and fracture. ME and EE, therefore, yield an attractive, inexpensive and fast supplement to conventional fracture test methods.

Similar content being viewed by others

References

see for example: ASTM E380 – 76, Standard for Metric Practice, and: DIN 1324 – 88 Elektromagnetisches Feld – Teil 1: Zustandsgrößen (in German).

Barkhausen, H. (1919). Zwei mit Hilfe der neuen Verstärker entdeckte Erscheinungen, Physik. Zeitschr. XX, S. 401–403 (in German).

J.T. Dickinson L. Jensen A. Jahan-Latibari (1984) ArticleTitleFracto-emission: The role of charge separation Journal of Vaccum Science and Technology A2 1112–1116 Occurrence Handle1984JVST....2.1112D

Ch. Kittel (1986) Introduction to Solid State Physics EditionNumber6 J. Wiley & Sons, Inc. New York

Lenkeyné, Gy. B. and Winkler, S. (1995). On the applicability of the magnetic emission technique for the determination of ductile crack initiation in impact tests, Proceedings of the 7th International Conference on Mechanical Behaviour of Materials, ICM 7, pp. 381–382, The Hague, The Netherlands, May 28–June 2, 1995.

Lenkeyné, Gy. B. and Winkler, S. (1996/1). A mágneses és elektro-emissziós méréstechnika alkalmazása műszerezett űtővizsgálatnál, Anyagvizsgálók Lapja, pp. 14–16, (in Hungarian)

Gy. B. Lenkeyné S. Winkler (1997) ArticleTitleOn the applicability of the magnetic emission technique for the determination of ductile crack initiation in impact tests Journal of Fatigue Fracture Engineering in Material Structure 20 IssueID2 143–150

Lenkeyné, Gy. B., Winkler, S. and Tóth, L. (1995a). Mágneses és elektro-emissziós méréstechnika alkalmazása műszerezett űtővizsgálattal, Proceedings of the Micro Cad 95, pp. 118–123, Miskolc, Hungary, February 21–24, 1995a (in Hungarian).

Lenkeyné, Gy. B., Winkler, S. and Tóth, L. (1995b) A reperdésterjedés körülményeinek viszgálata mágneses és elektroemissziós méréstechnikával müszerezett űtővizsgálatnál, Proceedings of the V. Törésmechanikai Szeminárium (Vth Hungarian Seminar on Fracture Mechanics), pp. 256–265, Miskolc-Tapolca, Hungary, April 3–6, 1995 (in Hungarian).

Lenkeyné, Gy. B., Winkler, S., Major, Z. and Lévay, I. (1996). Applicability of magnetic and electric emission techniques for detecting crack initiation, Proceedings of the 11th European Conference on Fracture, ECF 11, Vol III, pp. 2025–2034, Poitiers, France, September 3–6, 1996.

Sklarczyk, C., Altpeter, I., Winkler, S. and Thielicke, B. (1995). Grundlagenuntersuchungen zur Elektrischen Emission zur Erkennung wachsender Schädigungen insbesondere in Faserverbundwerkstoffen sowie zur berührungslosen Detektion von Schallwellen an dielektrischen Oberflächen, IzfP-Bericht 950129-TW (in German).

Winkler, S. (1988). Magnetische Emission, ein neues Brucherkennungsverfahren, Fraunhofer-IWM-Bericht T 3/88 (in German).

Winkler, S. (1990a). Brucherkennung mit elektrischer Emission, Fraunhofer-IWM-Bericht T 10/90 (in German).

Winkler, S.R. (1990b). Magnetic emission detection of crack Initiation, in ASTM STP 1074, Gudas, J. P., Joyce, J. A. and Hackett, E. M. (eds), American Society for Testing and Materials, Philadelphia, pp. 178–192.

see for instance: Winkler, S. (1991). On the Determination of Dynamic Properties of Instrumentation, Conference on Instrumented Impact Testing of Metallic Materials, National Physical Laboratory (NPL), Teddington, UK, 14–15 November 1991.

Winkler, S. (1993). Experimental Investigation of Wave and Fracture Phenomena in Impacted Ceramics, Experiments on Sapphire, IWM Project 301 388, Final Report, Contract US Army ERO DAJA45-90-C-0053, R&D 6472-MS-01, 27 September 1990, IWM-Bericht T 8/93, May 1993.

Winkler, S. (1997). Investigation of Critical Events During Loading and Fracturing of Samples or Structures Utilizing Magnetic and Electric Emission, Final Report, Contracting period February 1, 1994–January 31, 1997, German-Hungarian EU contract CIPA-CT93-0096, Commission of the European Communities, Brussels, February 1997, IWM-Bericht V 29/97.

Winkler, S., Winkler, W.-D. (1998). Fieldemission in Charpy Tests, Fa. Roell-Amsler-Symposium, Gottmadingen, 5 May 1998.

Winkler, S., Lenkey, Gy. B. and Gregor, M. (1998). Feldemissionen bei unterkritischem Risswachstum, Berichtsband zur 30. Tagung des AK

Bruchvorgänge

Bruchvorgänge  in Dresden, S. 141–150, 17–18 February 1998 (in German).

in Dresden, S. 141–150, 17–18 February 1998 (in German).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Winkler, S.R. Field Emissions Caused by Fracture and Yielding. Int J Fract 136, 221–235 (2005). https://doi.org/10.1007/s10704-005-6032-y

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10704-005-6032-y

Bruchvorgänge

Bruchvorgänge  in Dresden, S. 141–150, 17–18 February 1998 (in German).

in Dresden, S. 141–150, 17–18 February 1998 (in German).