Abstract

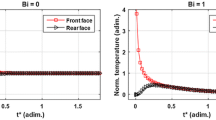

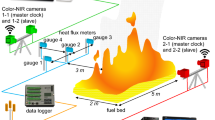

A novel non-intrusive measurement system based on quantitative infrared imaging has been designed and developed specifically for the study of composite plates submitted to fire. The system consists of two synchronized infrared cameras that image both sides of the sample during a fire test, providing surface temperature maps spatially corregistered. Flame effects on measured temperature are minimized through selection of a spectral band with near negligible infrared absorption-emission (wavelength centre 9585 nm, full width at half maximum 135 nm), as well as software post-processing. An ad hoc experiment has shown that this procedure retrieves surface temperatures with an uncertainty of \(\pm 5\) K, compared to a systematic error larger than 60 K for a classic thermographic measurement. Surface emissivities of both sides of the sample are measured and included in the retrieval procedure. By adding a flash lamp, the system implements an adaptation of the classical Parker’s flash method to thermally thick samples, providing also a map of thermal diffusivities along the sample both before and after the burning. In the region most degraded by fire, the effective thermal diffusivity is reduced approximately one order of magnitude as compared to the pre-test value (from 5.9 × 10−7 m2 s−1 to 0.5 × 10−7 m2 s−1). Several composite samples have been analysed while exposed to fire in different conditions, showing that thermal diffusivity after the burning shows a strong correlation with the local maximum temperature reached during the test. More precisely, in the temperature range between \(\sim \)325 and 350\(^{\circ }\)C a drastic change in diffusivity seems to takes place, in a way that suggest a phase change.

Similar content being viewed by others

References

Chung D (2010) Composite materials: science and applications, Springer, New York. doi:10.1007/978-1-84882-831-5

Gibson AG, Mouritz AP (2006) Fire properties of polymer composite materials. Springer, New York. doi:10.1007/978-1-4020-5356-6

Mouritz A, Feih S, Kandare E, Mathys Z, Gibson A, Jardin PD, Case S, Lattimer B (2009) Review of fire structural modelling of polymer composites. Composites A 40(12): 1800. doi:10.1016/j.compositesa.2009.09.001

Lattimer BJ, Oullette J, Trelles J (2011) Measuring properties for material decomposing modeling. Fire Mater 35(1):11. doi:10.1002/fam.1031

Branca C, Blasi CD, Galgano A, Milella E (2011) Thermal and kinetic characterization of a toughened epoxy resin reinforced with carbon fibers. Thermochim Acta 517(1–2):53. doi:10.1016/j.tca.2011.01.034

Dao DQ, Rogaume T, Luche J, Richard F, Valencia LB, Ruban S (2014) Thermal degradation of epoxy resin/carbon fiber composites: influence of carbon fiber fraction on the fire reaction properties and on the gaseous species release: thermal degradation of epoxy resin/carbon fiber composites. Fire Mater. doi:10.1002/fam.2265

Henderson JB, Wiebelt JA, Tant JA (1985) A model for the thermal response of polymer composite materials with experimental verification. J Compos Mater 19(6):579. doi:10.1177/002199838501900608

Dodds N, Gibson A, Dewhurst D, Davies J (2000) Fire behaviour of composite laminates. Composites A 31(7):689 (2000). doi:10.1016/S1359-835X(00)00015-4

Miano VU (2011) Modelling composite fire behaviour using apparent thermal diffusivity. Ph.D. thesis, Newcastle University, Newcastle upon Tyne

Gibson AG, Browne T, Feih S, Mouritz A (2012) Modeling of one-dimensional thermal response of silica-phenolic composites with volume ablation. J Compos Mater 46(16):2005. doi:10.1177/0021998311429383

Tranchard P, Samyn F, Duquesne S, Thomas M, Estebe B, Montes J, Bourbigot S (2015) Fire behaviour of carbon fibre epoxy composite for aircraft: Novel test bench and experimental study. J Fire Sci 33(3):247. doi:10.1177/0734904115584093

Meléndez J, Foronda A, Aranda JM, López F, López del Cerro FL (2007) Infrared thermography of solid surfaces in a fire. Meas Sci Technol 21(10):105504. doi:10.1088/0957-0233/21/10/105504

Babrauskas V (1995) Designing products for fire performance: the state of the art of test methods and fire models.Fire Saf J 24(3):299

Sorathia U, Divisjón C, Lyon R (1997) A review of fire test methods and criteria for C os. SAMPE J 33(4):23

ISO (1998) Iso2685:1998. Aircraft environmental test procedure for airborne equipment. Resistance to fire in designated fire zones. doi:10.3403/30320830u

FAA (2003) Far25.856(b):2003. Title 14 code of federal—test methods to determine the burnthrough rresistance of thermal/acoustic insulation materials (Appendix f, part vii)

Greene MCE http://www.marinecomposites.com

Parker W, Jenkins R, Butter C, Abbot GL (1961) Flash method of determining thermal diffusivity, heat capacity, and thermal conductivity . J Appl Phys 32:1679

Sánchez-Carballido S, Justo-María C, Meléndez J, López F, López del Cerro FJ (2013) Experimental determination of the thermal parameters of carbon fiber-composite materials exposed to fire by infrared imaging pulse thermography. Int J Thermophys 34(8−9):1606. doi:10.1007/s10765-013-1521-0

Baba T, Ono A (2001) Improvement of the laser flash method to reduce uncertainty in thermal diffusivity measurements. Meas Sci Technol 12(12):2046. doi:10.1088/0957-0233/12/12/304

Krankenhagen R, Maierhofer C (2014) Measurement of the radiative energy output of flash lamps by means of thermal thin probes. Infrared Phys Technol 67:363. doi:10.1016/j.infrared.2014.07.012. http://linkinghub.elsevier.com/retrieve/pii/S1350449514001364

Hibbard R, Liebert C (1970) Spectral emittance of soot. NASA Technical Notes

Dimitrienko Y (1997) Thermomechanical behaviour of composite materials and structures under high temperatures. Composites A 28(5):453. doi:10.1016/S1359-835X(96)00144-3

Stern S, Dierdorf D (2005) Thermogravimetric analysis (TGA) of various epoxy composite formulations. Technique Reports, DTIC Document

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sánchez-Carballido, S., Justo-María, C., Meléndez, J. et al. A Quantitative Infrared Imaging System for In Situ Characterization of Composite Materials in Fire Tests. Fire Technol 53, 1309–1331 (2017). https://doi.org/10.1007/s10694-016-0636-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10694-016-0636-9