The high operating speeds of crimping machines, the use of large packages on these units, and the machines’ ease of maintenance provide for high performance indices in the production of crimped carpet filaments. Controlling the counter-pressure that exists during the filling of the crimping chamber will ensure the production of filaments with a constant crimping length. A new piece of equipment that includes a step motor is proposed for controlling counter-pressure in the crimping chamber of machines used to produce textured carpet filaments.

Similar content being viewed by others

The high operating speeds of crimping machines, the use of large packages on these units, and the machines’ ease of maintenance provide for high performance indices in the production of crimped carpet filaments [1]. A substantial number of crimped filaments are also employed in the production of decorative and furniture fabrics [1], and thin crimped filaments are being successfully used to make outerwear - including sportswear and socks.

Crimping is an operation that is now being used in the processing of polyamide, polyester, and complex polyolefin filaments, as well as pellicular, planar, and fibrillar filaments with different linear densities and a pre-twist of no more than 100 twists/m [2].

The crimping mechanism often consists of a crimping chamber and a thermo-fixing chamber. The necessary curvature is imparted to a filament in the crimping chamber and the thus-formed structure is fixed in the thermo-fixing chamber. Counter-pressure needs to be applied as the filament leaves the pins on the cylinders and enters the crimping chamber in order to ensure that the necessary degree of instability is created. The filament will not become unstable in the absence of counter-pressure on it as it passes through the crimping and thermo-fixing chambers.

We will find the critical segment length l cr at which a filament becomes unstable under its own weight [3]. The critical length for polyamide filaments of rectangular cross section with densities of 266 and 644 tex is

where E is the first-order elastic modulus of the filament material (for a polyamide filament, E = 4000 MPa); J is the moment of inertia of the cross section of the filament, m4; g = 9.8 m/sec2 is acceleration due to gravity.

We calculate the moment of inertia of the cross section from the formula

where B = 0.005 m is the width of the sliver in accordance with the width of the feed rollers; h is the thickness of the sliver, m.

We find the thickness of the sliver from the formula

where q is the number of the sliver (kg/m), which in our case is equal to the linear density of the polyamide filament; ρ1 = 1140 kg/m3 is the linear density of the polyamide filament.

We calculate the number of the sliver from the formula:

where T is the linear density of the polyamide filament, tex.

It follows from the results of the experimental and theoretical calculations (Table 1) that no curves are formed in the filament if no counter-pressure is created inside the crimping and thermo-fixing chambers because l cr will be greater than the heights of those chambers. The critical segment length increases with an increase in the linear density of the filament. Counter-pressure must be created in the crimping chamber.

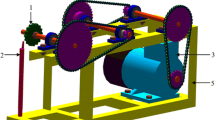

The stiffness of a polyamide filament of the above-indicated linear density was determined on the experimental unit depicted in Fig. 1.

As it unwinds from the feed packaging 1, the filament passes through the eye of the filament guide 2 and is pressed between cylinders 3 and 4. The shaft of the drive cylinder 3 is stationary, while the driven cylinder 4 is pressed against cylinder 3 by lever 7. As the filament leaves the pins on the cylinders, it becomes unstable (undergoes bending) for a certain period of time. In the case being discussed, cylinder 3 is stopped and the length of the bent segment of the filament is measured. The segment is then weighed on a VT-type torsion balance.

The stiffness values obtained by calculation were confirmed experimentally.

The counter-pressure should change as the crimping chamber fills. We will determine the necessary counterpressure during the filling of this chamber. The counter-pressure Q is specially created at the beginning of the process. Its required value should be at least as great as the critical force F cr, i.e. Q = F cr. For a filament of rectangular cross section, we calculate the critical force [3] by means of the formula

where I = 0.002 m - the length of the sliver segment that is being deformed.

With a full crimping chamber, the counter-pressure [3] is calculated from the formula

where F fr is the frictional force between the filament and the wall of the crimping chamber, N; P is the weight of the filament in the crimping chamber, kg; f = 04 is the friction coefficient for the friction of the filament against the wall of the crimping chamber; k f = 0.7 is the coefficient that characterizes the fullness of the crimping chamber; a, b, and z 1 are the dimensions of the crimping chamber; a = 0.006 m; b = 0.008 m; z = 0.045 m; S = ab, m2, is the cross-sectional area of the crimping chamber.

The frictional force of the filament on the wall of the crimping chamber is determined from the formula

where a = 0.006 m - the length of the crimping chamber; b = 0.008 m - the width of the crimping chamber; z = 0.045 m - the height of the crimping chamber; S = ab - the cross-sectional area of the crimping chamber, m2.

The weight of the filament is calculated from the formula

where k f is the coefficient that characterizes the fullness of the crimping chamber.

The results of the calculations are shown in Table 1.

Counter-pressure decreases from 1.65 to 0.14 N during the crimping operation. The crimping operation will be disrupted if the counter-pressure is constant. The equipment presently being used does not provide for a smooth change in counter-pressure, so it is being proposed here that a step motor be used.

There are many known methods of creating counter-pressure in a crimping chamber: filling the chamber with metal balls; the use of a valve controlled by a pneumatic or hydraulic device or a spring-controlled valve whose expanding force is regulated with a nut.

We propose replacing the spring (Fig. 2a) by a step motor (Fig. 2b), which makes it possible to control counterpressure automatically with the use of a microcontroller and microcomputer. We selected a motor from the standard CDROM of the drive to use in our study.

Step motor 6 is installed on housing 1. By turning shaft-worm 2, the motor induces lug 4 with weight 5 to move along guide 3 (Fig. 2b). The weight may move to the left or right, depending on the direction of motion of the shaft. A change in the position of the weight is accompanied by a change in the bending moment created by the device when it acts on lever 7. It thus presses against rod 10 and in so doing exerts force on valve 11, which provides the necessary counter-pressure.

The set point for counter-pressure is programmed into a microcomputer and subsequently forwarded to a microcontroller. Having processed this data, the microcontroller moves weight 5 along guide 3 to a prescribed position in accordance with the time it takes to fill the crimping chamber (Fig. 2b).

The program activates a timer at the beginning of the crimping operation, and the elapsed time is used to calculate the volume occupied by the filament in the crimping chamber at a given moment. After the filament volume becomes equal to the volume of the chamber, the program sends a signal to the step motor to return the weight to the neutral position. This lowers the counter-pressure to a minimum, which makes it possible for the now-curved filament to open the valve and proceed from the crimping chamber to the thermo-fixing chamber.

References

L. I. Koroteeva, O. N. Ozerskii, and A. P. Yaskin, Production Equipment of Factories That Make Chemical Filaments and Fibers [in Russian], Legpromizdat, Moscow (1987).

V. A. Usenko, Production of Twisted Textured Chemical Filaments, revised and enlarged 2nd edition. Legprombytizdat, Moscow (1987).

A. F. Proshkov, Planning and Design of Machines for Making Chemical Fibers [in Russian], Leg. i Pishch. Prom-st’, Moscow (2001).

Author information

Authors and Affiliations

Additional information

Translated from Khimicheskie Volokna, No. 3, pp. 58-60, May-June, 2012.

Rights and permissions

About this article

Cite this article

Kuzyakova, S.V., Stepnov, N.V. & Koroteeva, L.I. Designing a counter-pressure device for crimping filaments. Fibre Chem 44, 195–198 (2012). https://doi.org/10.1007/s10692-012-9428-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10692-012-9428-2