Abstract

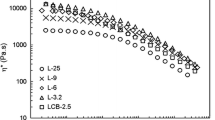

The viscosity properties of melts of fibre-forming polypropylene (PP) and poly(butylene terephthalate) blends were investigated in the entire range of ratios at different stresses and shear rate gradients at 230–250°C. It was shown that melts of fibre-forming PP and PBT blends are weakly crosslinked systems. The effect of the mass ratio of PP and PBT on the apparent activation energy of viscous flow of melts of the blends was investigated at different shear stresses and shear rate gradients. It was hypothesized that this blend can be assigned to the group of limitedly compatible systems. The probability of compatibility of the polymers in the melt appears when up to 20% PBT is incorporated in the PP. The blends are not compatible for the remaining ratios of polymers in the investigated system.

Similar content being viewed by others

References

A. A. Tager and V. S. Blinov, Usp. Khim., No. 6, 1004–1023 (1987).

B. E. Geller, Some Characteristics of Wet Spinning of Carbochain Fibres, Doctoral Dissertation, Leningrad Textile Institute, Leningrad (1964).

Yu. S. Lipatov, Colloid Chemistry of Polymers [in Russian], Naukova Dumka, Kiev (1984).

V. N. Kuleznev, Polymer Blends [in Russian], Khimiya, Moscow (1980).

A. A. Askadskii and V. I. Kondrashchenko, Computer Materials Science of Polymers. Vol. 1. The Atomic-Molecular Level [in Russian], Nauchnyi Mir, Moscow (1999).

B. E. Geller, A. A. Geller, et al., Kolloidn. Zh., No. 3, 391–395 (1972).

Yu. B. Monakov and B. E. Geller, in: Synthesis and Properties of Polymers [in Russian], Izd. Akad. Nauk SSSR, Ufa (1974), pp. 102–107.

I. Z. Zakirov, Physical Modification of Polyacrylonitrile Fibre [in Russian], Fan, Tashkent (1982).

A. Polson, Koll.-Z., 88, 51 (1939).

V. E. Gul’ and V. N. Kuleznev, Structure and Mechanical Properties of Polymers [in Russian], Vysshaya Shkola, Moscow (1972).

S. M. Lipatov (ed.), Physical Chemistry of Multicomponent Polymer Systems [in Russian], Vol. 2, Naukova Dumka, Kiev (1986).

H. D. Noethen, J. Polym. Sci. C, No. 16, 725–753 (1964).

M. Yokouchi, Y. Sakakibara, Y. Chatani, et al., Macromolecules, 9, No. 2, 266–273 (1976).

I. V. Akhortorr, Z. I. Salina, et al., Plast. Massy, No. 4, 7–8 (1992).

V. V. Lapkovskii and B. E. Geller, in: Proceedings of the International Scientific and Technical Conference “Latest Advances in Replacing Imports in the Chemical Industry and Production of Construction Materials” [in Russian], BGTU, Minsk (2004).

A. O. Lupezheva, N. I. Mashukov, and T. A. Borukaev, Plast. Massy, No. 11, 36–37 (2001).

O. V. Romankevich, A. D. Petukhov, and E. V. Butusov, Vestn. Gos. Akad. Leg. Prom-sti Ukr., No. 1, 27–29 (1999).

Author information

Authors and Affiliations

Additional information

__________

Translated from Khimicheskie Volokna, No. 5, pp. 17–21, September–October, 2006.

Rights and permissions

About this article

Cite this article

Kovaleva, E.V., Lapkovskii, V.V., Shevlik, N.V. et al. Study of the rheological properties of melts of polypropylene and poly(butylene terephthalate) blends. Fibre Chem 38, 365–369 (2006). https://doi.org/10.1007/s10692-006-0091-3

Issue Date:

DOI: https://doi.org/10.1007/s10692-006-0091-3