Abstract

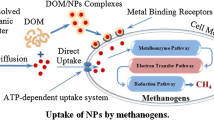

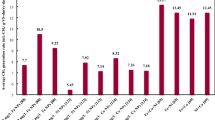

Recently, laser radiation and nanomaterials have been utilized to improve biogas yield via anaerobic digestion of herd’s manure through biostimulating methanogenic bacteria. Yet, laser irradiation and nanomaterials as anaerobic bacteria stimulant could have environmental impacts that have not been assessed or known. The aim of the current research was to understand and evaluate variable laser doses in the presence of nickel nanoparticles (Ni NPs) and their environmental impacts during the production of biogas from treated manure. A life cycle assessment scheme was employed to achieve this aim. The used laser doses were 0.5 h, 1 h and 2 h and correlated to 1-h incandescent light exposure, where all treatments received 2 g/m3 Ni NPs. The outcomes were conferred in the pattern of specific influences for the biogas utilization and production as an energy source. The studied impacts were global warming, greenhouse gas emissions mitigation, acidification, eutrophication, ozone layer depletion, freshwater ecotoxicity and prospective human toxicity. Results revealed that laser irradiation with the addition of Ni NPs during the biostimulation of anaerobic digestion has the least environmental adverse effects when compared to the control group.

Similar content being viewed by others

References

Abdelsalam, E., Hijazi, O., Samer, M., Yacoub, I. H., Ali, A. S., Ahmed, R. H., & Bernhardt, H. (2019). Life cycle assessment of the use of laser radiation in biogas production from anaerobic digestion of manure. Renewable Energy, 142, 130–136.

Abdelsalam, E. M., & Samer, M. (2019). Biostimulation of anaerobic digestion using nanomaterials for increasing biogas production. Reviews in Environmental Science and Bio/Technology, 18(3), 525–541.

Abdelsalam, E., Samer, M., Abdel-Hadi, M., Hassan, H., & Badr, Y. (2018a). Influence of laser irradiation on rumen fluid for biogas production from dairy manure. Energy, 163, 404–415.

Abdelsalam, E., Samer, M., Attia, Y., Abdel-Hadi, M. A., Hassan, H. E., & Badr, Y. (2018b). Effects of laser irradiation and Ni nanoparticles on biogas production from manure anaerobic digestion. Waste and Biomass Valorization. https://doi.org/10.1007/s12649-018-0374-y.

Abdelsalam, E., Samer, M., Attia, Y., Abdel-Hadi, M. A., Hassan, H. E., & Badr, Y. (2016). Comparison of nanoparticles effects on biogas and methane production from anaerobic digestion of cattle dung slurry. Renewable Energy, 87(1), 592–598.

Abdelsalam, E., Samer, M., Attia, Y., Abdel-Hadi, M. A., Hassan, H. E., & Badr, Y. (2017a). Influence of zero valent iron nanoparticles and magnetic iron oxide nanoparticles on biogas and methane production from anaerobic digestion of manure. Energy, 120, 842–853.

Abdelsalam, E., Samer, M., Attia, Y., Abdel-Hadi, M. A., Hassan, H. E., & Badr, Y. (2017b). Effects of Co and Ni nanoparticles on biogas and methane production from anaerobic digestion of slurry. Energy Conversion and Management, 14, 108–119.

Cano, P. I., Colon, J., Ramírez, M., Lafuente, J., Gabriel, D., & Cantero, D. (2018). Life cycle assessment of different physical-chemical and biological technologies for biogas desulfurization in sewage treatment plants. Journal of Cleaner Production, 181, 663–674.

Collet, P., Flottes, E., Favre, A., Raynal, L., Pierre, H., Capela, S., & Peregrina, C. (2017). Techno-economic and life cycle assessment of methane production via biogas upgrading and power to gas technology. Applied Energy, 192, 282–295.

Ertem, F. C., Neubauer, P., & Junne, S. (2017). Environmental life cycle assessment of biogas production from marine macroalgal feedstock for the substitution of energy crops. Journal of Cleaner Production, 140, 977–985.

Giwa, A. (2017). Comparative cradle-to-grave life cycle assessment of biogas production from marine algae and cattle manure biorefineries. Bioresource Technology, 244, 1470–1479.

Hijazi, O., Abdelsalam, E., Samer, M., Amer, B. M. A., Yacoub, I. H., Moselhy, M. A., et al. (2019). Environmental impacts concerning the addition of trace metals in the process of biogas production from anaerobic digestion of slurry. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2019.118593.

Hijazi, O., Abdelsalam, E., Samer, M., Attia, Y. A., Amer, B. M. A., Amer, M. A., et al. (2020). Life cycle assessment of the use of nanomaterials in biogas production from anaerobic digestion of manure. Renewable Energy, 148, 417–424.

Hijazi, O., Munro, S., Zerhusen, B., & Effenberger, M. (2016). Review of life cycle assessment for biogas production in Europe. Renewable and Sustainable Energy Reviews, 54, 1291–1300.

Kavitha, S., Kannah, R. Y., Yeom, I. T., Do, K.-U., & Banu, J. R. (2015). Combined thermo-chemo-sonic disintegration of waste activated sludge for biogas production. Bioresource Technology, 197, 383–392.

Koido, K., Takeuchi, H., & Hasegawa, T. (2018). Life cycle environmental and economic analysis of regional-scale food-waste biogas production with digestate nutrient management for fig fertilisation. Journal of Cleaner Production, 190, 552–562.

Li, H., Jin, C., Zhang, Z., O’Hara, I., & Mundree, S. (2017). Environmental and economic life cycle assessment of energy recovery from sewage sludge through different anaerobic digestion pathways. Energy, 126, 649–657.

Li, J., Wang, Y., & Yan, B. (2018). The hotspots of life cycle assessment for bioenergy: A review by social network analysis. Science of the Total Environment, 625, 1301–1308.

Lijo, L., Lorenzo-Toja, Y., González-García, S., Bacenetti, J., Negri, M., & Moreira, M. T. (2017). Eco-efficiency assessment of farm-scaled biogas plants. Bioresource Technology, 237, 146–155.

Lyng, K. A., & Brekke, A. (2019). Environmental life cycle assessment of biogas as a fuel for transport compared with alternative fuels. Energies, 12, 532. https://doi.org/10.3390/en12030532.

Nasution, M. A., Wibawa, D. S., Ahamed, T., & Noguchi, R. (2018). Comparative environmental impact evaluation of palm oil mill effluent treatment using a life cycle assessment approach: A case study based on composting and a combination for biogas technologies in North Sumatera of Indonesia. Journal of Cleaner Production, 184, 1028–1040.

Nikkhah, A., Khojastehpour, M., & Abbaspour-Fard, M. H. (2018). Hybrid landfill gas emissions modeling and life cycle assessment for determining the appropriate period to install biogas system. Journal of Cleaner Production, 185, 772–780.

Nuorkivi, A. (2010). Allocation of fuel energy and emissions to heat and power in CHP. Final report. Energy-AN Consulting

Pivato, A., Vanin, S., Raga, R., Lavagnolo, M. C., Barausse, A., Rieple, A., et al. (2016). Use of digestate from a decentralized on-farm biogas plant as fertilizer in soils: An ecotoxicological study for future indicators in risk and life cycle assessment. Waste Management, 49, 378–389.

Pérez-Camacho, M. N., Curry, R., & Cromie, T. (2018). Life cycle environmental impacts of substituting food wastes for traditional anaerobic digestion feedstocks. Waste Management, 73, 140–155.

Ramírez-Arpide, F. R., Demirer, G. N., Gallegos-Vazquez, C., Hernandez-Eugenio, G., Santoyo-Cortes, V. H., & Espinosa-Solares, T. (2018). Life cycle assessment of biogas production through anaerobic codigestion of nopal cladodes and dairy cow manure. Journal of Cleaner Production, 172, 2313–2322.

Ruiz, D., Miguel, G. S., Corona, B., Gaitero, A., & Domínguez, A. (2018). Environmental and economic analysis of power generation in a thermophilic biogas plant. Science of the Total Environment, 633, 1418–1428.

Samer, M. (2010). A software program for planning and designing biogas plants. Transactions of the ASABE, 53(4), 1277–1285.

Samer, M. (2012). Biogas plant constructions. In S. Kumar (Ed.), Biogas (pp. 343–68). Rijeka, Croatia: InTech. https://doi.org/10.5772/31887.

Samer, M. (2016). Abatement techniques for reducing emissions from livestock buildings, Springer briefs in environmental science. Switzerland: Springer International Publishing. https://doi.org/10.1007/978-3-319-28838-3.

Stappen, F. V., Mathot, M., Decruyenaere, V., Loriers, A., Delcour, A., Planchon, V., et al. (2016). Consequential environmental life cycle assessment of a farm-scale biogas plant. Journal of Environmental Management, 175, 20–32.

Styles, D., Dominguez, E. M., & Chadwick, D. (2016). Environmental balance of the UK biogas sector: An evaluation by consequential life cycle assessment. Science of the Total Environment, 560–561, 241–253.

Wang, Q.-L., Li, W., Gao, X., & Li, S.-J. (2016). Life cycle assessment on biogas production from straw and its sensitivity analysis. Bioresource Technology, 201, 208–214.

Wang, Y., Wu, X., Tong, X., Li, T., & Wu, F. (2018). Life cycle assessment of large-scale and household biogas plants in northwest China. Journal of Cleaner Production, 192, 221–235.

Wolf, C., Dressler, D., Engelmann, K., Klein, D., Weber-Blaschke, G., Böswirth, T., Bryzinski, T., Effenberger, M., Hijazi, O., Hülsbergen, K. J., Maze. M., Remmele, E., Richter, K., Röder, H., Schulz, C., Serdjuk, M., Thuneke, K., Tiemann, A., Zerle, P. (2016). Methoden zur Analyse und Bewertung ausgewählter ökologischer und ökonomischer Wirkungen von Produktsystemen aus land- und forstwirtschaftlichen Rohstoffen (In German: Methods to analyze and evaluate selected environmental and economic impacts of product systems derived from agricultural and forestry resources). ExpRessBio, Berichte aus dem TFZ, No. 45, ISBN 1614–1008, 165 p. http://www.tfz.bayern.de/mam/cms08/biokraftstoffe/dateien/tfz_bericht_45_expressbio.pdf

Yasar, A., Rasheed, R., Tabinda, A. B., Tahir, A., & Sarwar, F. (2017). Life cycle assessment of a medium commercial scale biogas plant and nutritional assessment of effluent slurry. Renewable and Sustainable Energy Reviews, 67, 364–371.

Acknowledgements

The authors thank the National Institute of Laser Enhanced Science (NILES) and Cairo University for the scientific, technical support and funding the research work.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Samer, M., Hijazi, O., Abdelsalam, E.M. et al. Life cycle assessment of using laser treatment and nanomaterials to produce biogas through anaerobic digestion of slurry. Environ Dev Sustain 23, 14683–14696 (2021). https://doi.org/10.1007/s10668-021-01264-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-021-01264-9