Abstract

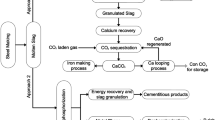

Along with iron and steel production, large amount of slag is generated. Proper management on the iron- and steelmaking slag is highly demanded due to the high cost of direct disposal of the slag to landfill, which is the most adopted management approach. In this article, the potential application of iron- and steelmaking slag has been reviewed, which included the slag utilization in construction as cement and sand, in water, soil, and gas treatment, as well as in value material recovery. In addition, the challenge and required effort to be made in iron- and steelmaking slag management have been discussed.

Similar content being viewed by others

References

Ahmaruzzaman, M. (2011). Industrial wastes as low-cost potential adsorbents for the treatment of wastewater laden with heavy metals. Advances in Colloid and Interface Science,166(1), 36–59.

Alanyali, H., Col, M., Yilmaz, M., & Karagoz, S. (2009). Concrete produced by steel-making slag (basic oxygen furnace) addition in portland cement. International Journal of Applied Ceramic Technology,6, 736–748.

Ali, M. T., & Shahram, S. H. (2007). Converter slag as a liming agent in the amelioration of acidic soils. International Journal of Agriculture & Biology,5, 715–720.

Apul, D., Gardner, K., & Taylloreighmy, T. (2005). Simultaneous application of dissolution/precipitation and surface complexation/surface precipitation modeling to contaminant leaching. Environmental Science and Technology,39, 5736–5741.

Aramouni, N. A. K., Touma, J. G., Tarboush, B. A., Zeaiter, J., & Ahmad, M. N. (2018). Catalyst design for dry reforming of methane: Analysis review. Renewable and Sustainable Energy Reviews,82(Part 3), 2570–2585.

Baciocchi, R., Costa, G., Polettini, A., & Pomi, R. (2015). Effects of thin-film accelerated carbonation on steel slag leaching. Journal of Hazardous Materials,286(Supplement C), 369–378.

Balczár, I., Korim, T., Hullár, H., Boros, A., & Makó, É. (2017). Manufacture of air-cooled slag-based alkali-activated cements using mechanochemical activation. Construction and Building Materials,137(Supplement C), 216–223.

Bao, W., Li, H., & Zhang, Y. (2010). Selective leaching of steelmaking slag for indirect CO2 mineral sequestration. Industrial and Engineering Chemistry Research,49, 2055–2063.

Barca, C., Gérente, C., Meyer, D., Chazarenc, F., & Andrès, Y. (2012). Phosphate removal from synthetic and real wastewater using steel slags produced in Europe. Water Research,46(7), 2376–2384.

Barca, C., Meyer, D., Liira, M., Drissen, P., Comeau, Y., Andrès, Y., et al. (2014). Steel slag filters to upgrade phosphorus removal in small wastewater treatment plants: Removal mechanisms and performance. Ecological Engineering,68(Supplement C), 214–222.

Barca, C., Roche, N., Troesch, S., Andrès, Y., & Chazarenc, F. (2018). Modelling hydrodynamics of horizontal flow steel slag filters designed to upgrade phosphorus removal in small wastewater treatment plants. Journal of Environmental Management,206(Supplement C), 349–356.

Basu, S., Lahiri, A. K., & Seetharaman, S. (2008). Activity of iron oxide in steelmaking slag. Metallurgical and Materials Transactions B,39, 447–456.

Battsengel, A., Batnasan, A., Narankhuu, A., Haga, K., Watanabe, Y., & Shibayama, A. (2018). Recovery of light and heavy rare earth elements from apatite ore using sulphuric acid leaching, solvent extraction and precipitation. Hydrometallurgy, 179, 100–109.

Beh, C. L., Chuah, L., Choong, T. S. Y., Kamarudzaman, M. Z. B., & Abdan, K. (2010). Adsorption study of electric arc furnace slag for the removal of manganese from solution. American Journal of Applied Sciences,7, 442–446.

Biskri, Y., Achoura, D., Chelghoum, N., & Mouret, M. (2017). Mechanical and durability characteristics of high performance concrete containing steel slag and crystalized slag as aggregates. Construction and Building Materials,150(Supplement C), 167–178.

Bodurtha, P., & Brassard, P. (2000). Neutralization of acid by steel-making slags. Environmental Technology,21, 1271–1281.

Burciaga-Díaz, O., & Escalante-García, J. I. (2017). Comparative performance of alkali activated slag/metakaolin cement pastes exposed to high temperatures. Cement & Concrete Composites,84(Supplement C), 157–166.

Cantarino, M. V., de Carvalho Filho, C., & Borges Mansur, M. (2012). Selective removal of zinc from basic oxygen furnace sludges. Hydrometallurgy,111–112(Supplement C), 124–128.

Carvalho, S. Z., Vernilli, F., Almeida, B., Demarco, M., & Silva, S. N. (2017). The recycling effect of BOF slag in the portland cement properties. Resources, Conservation and Recycling,127(Supplement C), 216–220.

Chen, S.-H., Lin, D.-F., Luo, H.-L., & Lin, Z.-Y. (2017). Application of reclaimed basic oxygen furnace slag asphalt pavement in road base aggregate. Construction and Building Materials,157(Supplement C), 647–653.

Claveau-Mallet, D., Courcelles, B., Pasquier, P., & Comeau, Y. (2017). Numerical simulations with the P-Hydroslag model to predict phosphorus removal by steel slag filters. Water Research,126(Supplement C), 421–432.

Claveau-Mallet, D., Wallace, S., & Comeau, Y. (2013). Removal of phosphorus, fluoride and metals from a gypsum mining leachate using steel slag filters. Water Research,47(4), 1512–1520.

Coppola, L., Buoso, A., Coffetti, D., Kara, P., & Lorenzi, S. (2016). Electric arc furnace granulated slag for sustainable concrete. Construction and Building Materials,123(Supplement C), 115–119.

Curkovii, L., Cerjan-Stefanovii, S., & Rastovean-Mioe, A. (2000). Batch Pb2+ and Cu2+ removal by electric furnace slag. Water Research,35, 3436–3440.

Da’na, E., & Awad, A. (2017). Regeneration of spent activated carbon obtained from home filtration system and applying it for heavy metals adsorption. Journal of Environmental Chemical Engineering,5(4), 3091–3099.

Danilov, E. V. (2003). Modern technology for recycling steelmaking slags. Metallurgist,47, 232–234.

Dieter, G., Karl, W., & Konrad, M. (1988). Process and device for producing granulated slag sand from blast furnace slag. Application Number: 07/004475.

Dimitrova, S. V. (1996). Metal sorption on Blast-furnace slag. Water Research,30, 228–232.

Dimitrova, S. V. (2002). Use of granular slag columns for lead removal. Water Research,36, 4001–4008.

Duan, J., & Su, B. (2014). Removal characteristics of Cd(II) from acidic aqueous solution by modified steel-making slag. Chemical Engineering Journal,246(Supplement C), 160–167.

El-Naas, M. H., El Gamal, M., Hameedi, S., & Mohamed, A.-M. O. (2015). CO2 sequestration using accelerated gas-solid carbonation of pre-treated EAF steel-making bag house dust. Journal of Environmental Management,156(Supplement C), 218–224.

Emery, J. (1992). Mineral aggregate conservation reuse and recycling. Report prepared by Geotechnical Engineering Limited for Aggregate and Petroleum Resources Section, Ontario Ministry of Natural Resources, Ontario, 1992.

Ferreira, V. J., Sáez-De-Guinoa Vilaplana, A., García-Armingol, T., Aranda-Usón, A., Lausín-González, C., López-Sabirón, A. M., et al. (2016). Evaluation of the steel slag incorporation as coarse aggregate for road construction: technical requirements and environmental impact assessment. Journal of Cleaner Production,130(Supplement C), 175–186.

Fidalgo, B., Bermudez, J. M., Arenillas, A., & Menendez, J. A. (2009). Steel-making slag as catalyst for dry reforming of CH4. In 1st Spanish national conference on advances in materials recycling and eco-energy, Madrid, November 12–13, 2009, S04-01.

Gahan, C. S., Cunha, M. L., & Sandström, Å. (2009). Comparative study on different steel slags as neutralising agent in bioleaching. Hydrometallurgy,95(3), 190–197.

Gao, H., Song, Z., Zhang, W., Yang, X., Wang, X., & Wang, D. (2017). Synthesis of highly effective absorbents with waste quenching blast furnace slag to remove methyl orange from aqueous solution. Journal of Environmental Sciences,53(Supplement C), 68–77.

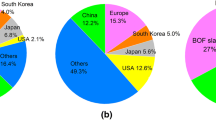

Geiseler, J. (1996). Use of steelworks slag in Europe. Waste Management,16, 59–63.

Genç-Fuhrman, H., Mikkelsen, P. S., & Ledin, A. (2007). Simultaneous removal of As, Cd, Cr, Cu, Ni and Zn from stormwater: Experimental comparison of 11 different sorbents. Water Research, 41(3), 591–602.

Ghouleh, Z., Guthrie, R. I. L., & Shao, Y. (2017). Production of carbonate aggregates using steel slag and carbon dioxide for carbon-negative concrete. Journal of CO2 Utilization,18(Supplement C), 125–138.

Goetz, E. R., & Riefler, R. G. (2014). Performance of steel slag leach beds in acid mine drainage treatment. Chemical Engineering Journal,240(Supplement C), 579–588.

Gomes, J. F. P., & Pinto, C. G. (2006). Leaching of heavy metals from steelmaking slags. Revista De Metalurgia,42, 409–416.

Gopinath, S., & Mehra, A. (2016). Carbon sequestration during steel production: Modelling the dynamics of aqueous carbonation of steel slag.”. Chemical Engineering Research and Design,115(Part A), 173–181.

Han, C., Wang, Z., Yang, W., Wu, Q., Yang, H., & Xue, X. (2016). Effects of pH on phosphorus removal capacities of basic oxygen furnace slag. Ecological Engineering,89(Supplement C), 1–6.

Han, C., Wang, Z., Yang, H., & Xue, X. (2015). Removal kinetics of phosphorus from synthetic wastewater using basic oxygen furnace slag. Journal of Environmental Sciences,30(Supplement C), 21–29.

Hashim, M. A., Mukhopadhyay, S., Sahu, J. N., & Sengupta, B. (2011). Remediation technologies for heavy metal contaminated groundwater. Journal of Environmental Management,92(10), 2355–2388.

He, H., Tam, N. F. Y., Yao, A., Qiu, R., Li, W. C., & Ye, Z. (2017). Growth and Cd uptake by rice (Oryza sativa) in acidic and Cd-contaminated paddy soils amended with steel slag. Chemosphere,189(Supplement C), 247–254.

Heikal, M., Al-Duaij, O. K., & Ibrahim, N. S. (2015). Microstructure of composite cements containing blast-furnace slag and silica nano-particles subjected to elevated thermally treatment temperature. Construction and Building Materials,93(Supplement C), 1067–1077.

Heribeert, M., & Kuehn, M. (2004). Iron and steel slags as sustainable construction resources and fertilizer. In SCANMET-2nd international conference on process development in iron and steel making, Sweden (pp. 347–358).

Hiroyuki, T., Koichi, T., & Tatsuhito, T. (2005). Steelmaking slag: uses and trends of development of uses. Current Advances in Materials and Processes,18, 1060–1072.

Hocheng, H., Su, C., & Jadhav, U. U. (2014). Bioleaching of metals from steel slag by Acidithiobacillus thiooxidans culture supernatant. Chemosphere,117(Supplement C), 652–657.

Huijgen, W. J. J., & Comans, R. N. J. (2003). Carbon dioxide sequestration by mineral carbonation, literature review. ECN School Fossiel: Netherlands,1, 1–13.

Ichikawa, H., & Morishige, H. (2002). Effective use of steelmaking dust and sludge by use of Rotary Hearth Furnace. Nippon Steel Technical Report No. 86 July 2002.

Jalkanen, H., Oghbasilasie, H., & Raipala, K. (2005). Recycling of steelmaking dusts-the radust concept. Journal of Mining and Metallurgy,41B, 1–16.

Jha, V. K., Kameshima, Y., Nakajima, A., & Okada, K. (2004). Hazardous ions uptake behavior of thermally activated steel-making slag. Journal of Hazardous Materials,114(1), 139–144.

Jha, V. K., Kameshima, Y., Nakajima, A., & Okada, K. (2008). Utilization of steel-making slag for the uptake of ammonium and phosphate ions from aqueous solution. Journal of Hazardous Materials,156(1), 156–162.

Jo, Y., Kim, J., Hwang, S., & Lee, C. (2015). Anaerobic treatment of rice winery wastewater in an upflow filter packed with steel slag under different hydraulic loading conditions. Bioresource Technology,193(Supplement C), 53–61.

Jukes, L. M. (2003). The volume stability of modern steel making slag. Mineral Processing and Extractive Metallurgy,112, 177–197.

Kadirova, Z. C., Hojamberdiev, M., Bo, L., Hojiyev, R., & Okada, K. (2015). Simultaneous removal of NH4+, H2PO4− and Ni2+ from aqueous solution by thermally activated combinations of steel converter slag and spent alumina catalyst. Journal of Water Process Engineering,8(Supplement C), 151–159.

Kalyoncu, R. S. (2000). Slag-iron and steel. U.S. Geological survey minerals yearbook 2000 (Vol. 71, pp. 1–3).

Kambole, C., Paige-Green, P., Kupolati, W. K., Ndambuki, J. M., & Adeboje, A. O. (2017). Basic oxygen furnace slag for road pavements: A review of material characteristics and performance for effective utilisation in southern Africa. Construction and Building Materials,148(Supplement C), 618–631.

Karnib, M., Kabbani, A., Holail, H., & Olama, Z. (2014). Heavy metals removal using activated carbon, silica and silica activated carbon composite. Energy Procedia,50(Supplement C), 113–120.

Ke, X., Bernal, S. A., & Provis, J. L. (2016). Controlling the reaction kinetics of sodium carbonate-activated slag cements using calcined layered double hydroxides. Cement and Concrete Research,81(Supplement C), 24–37.

Kim, D.-H., Shin, M.-C., Choi, H.-D., Seo, C.-I., & Baek, K. (2008). Removal mechanisms of copper using steel-making slag: adsorption and precipitation. Desalination,223, 283–289.

Lan, Y.-P., Liu, Q.-C., Meng, F., Niu, D.-L., & Zhao, H. (2017). Optimization of magnetic separation process for iron recovery from steel slag. Journal of Iron and Steel Research International,24(2), 165–170.

Le, D.-H., Sheen, Y.-N., & Bui, Q.-B. (2017). An assessment on volume stabilization of mortar with stainless steel slag sand. Construction and Building Materials,155(Supplement C), 200–208.

Lenz, D. M., & Martins, F. B. (2007). Lead and zinc selective precipitation from leach electric arc furnace dust solutions. Revista Materia,12, 503–509.

Li, Y., & Dai, W.-B. (2018). Modifying hot slag and converting it into value-added materials: A review. Journal of Cleaner Production,175(Supplement C), 176–189.

Li, Q., Ding, H., Rahman, A., & He, D. (2016). Evaluation of basic oxygen furnace (BOF) material into slag-based asphalt concrete to be used in railway substructure. Construction and Building Materials,115(Supplement C), 593–601.

Li, W., Lang, L., Wang, D., Wu, Y., & Li, F. (2018). Investigation on the dynamic shear modulus and damping ratio of steel slag sand mixtures. Construction and Building Materials,162(Supplement C), 170–180.

Li, H., Li, Y., Gong, Z., & Li, X. (2013). Performance study of vertical flow constructed wetlands for phosphorus removal with water quenched slag as a substrate. Ecological Engineering,53(Supplement C), 39–45.

Lobato, N. C. C., Villegas, E. A., & Mansur, M. B. (2015). Management of solid wastes from steelmaking and galvanizing processes: A brief review. Resources, Conservation and Recycling,102(Supplement C), 49–57.

Lu, S.-G., Bai, S.-Q., & Shan, H.-D. (2008). Mechanisms of phosphate removal from aqueous solution by blast furnace slag and steel furnace slag. Journal of Zhejiang University Science A,9, 125–132.

Masindi, V., Osman, M. S., & Abu-Mahfouz, A. M. (2017). Integrated treatment of acid mine drainage using BOF slag, lime/soda ash and reverse osmosis (RO): Implication for the production of drinking water. Desalination,424(Supplement C), 45–52.

Masindi, V., Osman, M. S., Mbhele, R. N., & Rikhotso, R. (2018). Fate of pollutants post treatment of acid mine drainage with basic oxygen furnace slag: Validation of experimental results with a geochemical model. Journal of Cleaner Production,172(Supplement C), 2899–2909.

McIntosh, S. N., & Baglin, E. G. (1992). Recovery of manganese from steel plant slag by carbamate leaching. Report of Investigation.

Mercado-Borrayo, B. M., Schouwenaars, R., Litter, M. I., Montoya-Bautista, C. V., & Ramírez-Zamora, R. M. (2014). 5—Metallurgical slag as an efficient and economical adsorbent of arsenic. In S. Ahuja (Ed.), Water reclamation and sustainability (pp. 95–114). Boston: Elsevier.

Mihok, L., Demeter, P., Baricova, D., & Seilerova, K. (2006). Utilization of ironmaking and steelmaking slags. Metalurgija,45, 163–168.

Moodley, I., Sheridan, C. M., Kappelmeyer, U., & Akcil, A. (2017). Environmentally sustainable acid mine drainage remediation: Research developments with a focus on waste/by-products. Minerals Engineering,126, 207–220.

Murthy, I. N., & Rao, J. B. (2016). Investigations on physical and chemical properties of high silica sand, Fe–Cr slag and blast furnace slag for foundry applications. Procedia Environmental Sciences,35(Supplement C), 583–596.

Negim, O., Eloifi, B., Mench, M., Bes, C., Gaste, H., Motelica-Heino, M., et al. (2010). Effect of basic slag addition on soil properties, growth and leaf mineral composition of beans in a Cu-contaminated soil. Journal Soil and Sediment Contamination,19, 174–187.

Oh, C., Rhee, S., Oh, M., & Park, J. (2012). Removal characteristics of As(III) and As(V) from acidic aqueous solution by steel making slag. Journal of Hazardous Materials,213–214(Supplement C), 147–155.

Okada, K., Yamamoto, T., Kim, K.-H., Asaoka, S., Hayakawa, S., Takeda, K., et al. (2014). Removal of hydrogen sulfide with steelmaking slag by concurrent reactions of sulfide mineralization and oxidation. Ecological Engineering,63(Supplement C), 122–126.

Orhan, G. (2005). Leaching and cementation of heavy metals from electric arc furnace dust in alkaline medium. Hydrometallurgy,78(3–4), 236–245.

Ouda, A. S., & Abdel-Gawwad, H. A. (2017). The effect of replacing sand by iron slag on physical, mechanical and radiological properties of cement mortar. HBRC Journal,13(3), 255–261.

Pan, S.-Y., Adhikari, R., Chen, Y.-H., Li, P., & Chiang, P.-C. (2016). Integrated and innovative steel slag utilization for iron reclamation, green material production and CO2 fixation via accelerated carbonation. Journal of Cleaner Production,137(Supplement C), 617–631.

Pap, S., Šolević Knudsen, T., Radonić, J., Maletić, S., Igić, S. M., & Turk Sekulić, M. (2017). Utilization of fruit processing industry waste as green activated carbon for the treatment of heavy metals and chlorophenols contaminated water. Journal of Cleaner Production,162(Supplement C), 958–972.

Park, T., Ampunan, V., Maeng, S., & Chung, E. (2017). Application of steel slag coated with sodium hydroxide to enhance precipitation-coagulation for phosphorus removal. Chemosphere,167(Supplement C), 91–97.

Pasetto, M., Baliello, A., Giacomello, G., & Pasquini, E. (2017). Sustainable solutions for road pavements: A multi-scale characterization of warm mix asphalts containing steel slags. Journal of Cleaner Production,166(Supplement C), 835–843.

Peters, M. A., & Colo, A. (1978). Process for recovering zinc from steel-making flue dust. United States Patent 4071357.

Piatak, N. M., Parsons, M. B., & Seal, R. R. (2015). Characteristics and environmental aspects of slag: A review. Applied Geochemistry,57(Supplement C), 236–266.

Qiu, H., Gu, H.-H., He, E.-K., Wang, S.-Z., & Qiu, R.-L. (2012). Attenuation of metal bioavailability in acidic multi-metal contaminated soil treated with fly ash and steel slag. Pedosphere,22(4), 544–553.

Rawlins, C. H. (2008). Geological sequestration of carbon dioxide by hydrous carbonate formation in steelmaking slag a dissertation. Doctoral thesis presented to the Faculty of the Graduate School of the Missouri University of Science and Technology, pp. 1–247.

Reddy, A. S., Pradhan, R. K., & Chandra, S. (2006). Utilization of basic oxygen furnace (BOF) slag in the production of a hydraulic cement binder. International Journal of Mineral Processing,79, 98–105.

Reis da Silva, J.-B., Gois de Carvalho, K.-M., Bicudo Filho, P.-S., de Abreu, L.-D., & Rossi, L.-A. (2007). Environmental risks analysis on LD steel making slag use for road pavement applications. Revue de Métallurgie,11, 540–550.

Santamaría, A., Orbe, A., Losañez, M. M., Skaf, M., Ortega-Lopez, V., & González, J. J. (2017). Self-compacting concrete incorporating electric arc-furnace steelmaking slag as aggregate. Materials and Design,115(Supplement C), 179–193.

Santos, R. M., Van Bouwel, J., Vandevelde, E., Mertens, G., Elsen, J., & Van Gerven, T. (2013). Accelerated mineral carbonation of stainless steel slags for CO2 storage and waste valorization: Effect of process parameters on geochemical properties. International Journal of Greenhouse Gas Control,17(Supplement C), 32–45.

Sarkar, C., Basu, J. K., & Samanta, A. N. (2017). Removal of Ni2+ ion from waste water by geopolymeric adsorbent derived from LD slag. Journal of Water Process Engineering,17(Supplement C), 237–244.

Senani, M., Ferhoune, N., & Guettala, A. (2016). Substitution of the natural sand by crystallized slag of blast furnace in the composition of concrete. Alexandria Engineering Journal,57, 851–857.

Shen, H., & Forssberg, E. (2003). An overview of recovery of metals from slags. Waste Management,23(10), 933–949.

Spooren, J., Kim, E., Horckmans, L., Broos, K., Nielsen, P., & Quaghebeur, M. (2016). In-situ chromium and vanadium recovery of landfilled ferrochromium and stainless steel slags. Chemical Engineering Journal,303(Supplement C), 359–368.

Sun, Y., Yao, M.-S., Zhang, J.-P., & Yang, G. (2011). Indirect CO2 mineral sequestration by steelmaking slag with NH4Cl as leaching solution. Chemical Engineering Journal,173(2), 437–445.

Sun, S., & Yuan, Y. (1983). Study of steel slag cement. Silicates Industrials,2, 31–34.

Takahashi, T., & Yabuta, K. (2002). New applications for iron and steelmaking slag. NKK Technical Review,87, 39–44.

Tang, M.-T., Peng, J., Peng, B., Yu, D., & Tang, C.-B. (2008). Thermal solidification of stainless steelmaking dust. Transactions of the Nonferrous Metals Society of China,18, 202–206.

Tsutsumi, T., Nishimoto, S., Kameshima, Y., & Miyake, M. (2014). Hydrothermal preparation of tobermorite from blast furnace slag for Cs+ and Sr2+ sorption. Journal of Hazardous Materials,266(Supplement C), 174–181.

Turhan, B. (2006). Use of granulated blast-furnace slag in concrete as fine aggregate. ACI Materials Journal,103, 203–208.

Ukwattage, N. L., Ranjith, P. G., & Li, X. (2017). Steel-making slag for mineral sequestration of carbon dioxide by accelerated carbonation. Measurement,97(Supplement C), 15–22.

Velenturf, A. P. M., Archer, S. A., Gomes, H. I., Christgen, B., Lag-Brotons, A. J., & Purnell, P. (2019). Circular economy and the matter of integrated resources. Science of the Total Environment,689, 963–969.

Vijayaraghavan, J., Jude, A. B., & Thivya, J. (2017). Effect of copper slag, iron slag and recycled concrete aggregate on the mechanical properties of concrete. Resources Policy,53(Supplement C), 219–225.

Wang, G. C. (2016). 9—Usability criteria for slag use as a granular material. In G. C. Wang (Ed.), The utilization of slag in civil infrastructure construction (pp. 185–199). Cambridge: Woodhead Publishing.

Wang, X., & Cai, Q.-S. (2006). Steel slag as an iron fertilizer for corn growth and soil improvement in a pot experiment. Pedosphere,16(4), 519–524.

Wang, H., Ding, B., Liu, X.-Y., Zhu, X., He, X.-Y., & Liao, Q. (2017). Solidification behaviors of a molten blast furnace slag droplet cooled by air. Applied Thermal Engineering,127(Supplement C), 915–924.

Wang, P., Kara, S., & Hauschild, M. Z. (2018). Role of manufacturing towards achieving circular economy: The steel case. CIRP Annals,67(1), 21–24.

Wang, Y., & Lin, D. (1983). The steel slag blended cement. Silicates Industrials,6, 121–126.

Worldsteel Association (2016). Retrieved September 15, 2017 from http://www.worldsteel.org/statistics/crude-steelproduction.html.

Wu, Q., You, R., Clark, M., & Yu, Y. (2014). Pb(II) removal from aqueous solution by a low-cost adsorbent dry desulfurization slag. Applied Surface Science,314(Supplement C), 129–137.

Xiang, J., Huang, Q., Lv, X., & Bai, C. (2018). Extraction of vanadium from converter slag by two-step sulfuric acid leaching process. Journal of Cleaner Production,170(Supplement C), 1089–1101.

Xie, M., Leung, A. K., & Ng, C. W. W. (2017). Mechanisms of hydrogen sulfide removal by ground granulated blast furnace slag amended soil. Chemosphere,175(Supplement C), 425–430.

Xue, Y., Hou, H., & Zhu, S. (2009). Competitive adsorption of copper(II), cadmium(II), lead(II) and zinc(II) onto basic oxygen furnace slag. Journal of Hazardous Materials,162, 391–401.

Yildirim, I. Z., & Prezzi, M. (2017). Experimental evaluation of EAF ladle steel slag as a geo-fill material: Mineralogical, physical & mechanical properties. Construction and Building Materials,154(Supplement C), 23–33.

Yilmaz, D., Lassabatere, L., Angulo-Jaramillo, R., Deneele, D., & Legret, M. (2010). Hydrodynamic characterization of basic oxygen furnace slag through an adapted BEST method. Vadose Zone,9, 107–116.

Yu, J., Liang, W., Wang, L., Li, F., Zou, Y., & Wang, H. (2015). Phosphate removal from domestic wastewater using thermally modified steel slag. Journal of Environmental Sciences,31(Supplement C), 81–88.

Yuan, B., Straub, C., Segers, S., Yu, Q. L., & Brouwers, H. J. H. (2017). Sodium carbonate activated slag as cement replacement in autoclaved aerated concrete. Ceramics International,43(8), 6039–6047.

Zahar, M. S. M., Kusin, F. M., & Muhammad, S. N. (2015). Adsorption of manganese in aqueous solution by steel slag. Procedia Environmental Sciences,30(Supplement C), 145–150.

Zhang, F.-S., & Itoh, H. (2006). Photocatalytic oxidation and removal of arsenite from water using slag-iron oxide-TiO2 adsorbent. Chemosphere,65(1), 125–131.

Zhou, W., Huang, Z., Sun, C., Zhao, H., & Zhang, Y. (2016). Enhanced phosphorus removal from wastewater by growing deep-sea bacterium combined with basic oxygen furnace slag. Bioresource Technology,214(Supplement C), 534–540.

Zuo, M., Renman, G., Gustafsson, J. P., & Renman, A. (2015). Phosphorus removal performance and speciation in virgin and modified argon oxygen decarburisation slag designed for wastewater treatment. Water Research,87(Supplement C), 271–281.

Acknowledgements

Sincere thanks are due to the grant Major Project of National Water Pollution Control and Governance of Science and Technology (2017ZX07401001) and Shenzhen scientific research foundation for high-level talent (KQJSCX20180328165658476), and Shenzhen scientific fundamental research foundation (JCYJ20180306171843211) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, X., Chen, J., Jiang, J. et al. The potential utilization of slag generated from iron- and steelmaking industries: a review. Environ Geochem Health 42, 1321–1334 (2020). https://doi.org/10.1007/s10653-019-00419-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10653-019-00419-y