Abstract

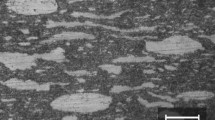

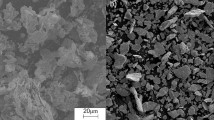

Metallic glass particle reinforced Al-based and (Al-Ni)-based metal matrix composites are obtained by explosive compaction of powders. These composites contain no Mach holes, cracks, or other obvious defects. The mass fraction of the amorphous phase is varied from 5 to 20%. The x-ray diffraction and differential thermal analysis of the composite specimens show that the amorphous phase is maintained in the composites without crystallization during the compaction. Furthermore, photographs of the composites obtained on a scanning electron microscope show that the metallic glass particles are uniformly distributed in the matrix. Compared to monolithic aluminum, the composites have a higher Rockwell hardness proportional to the mass fraction of the reinforcing amorphous phase.

Similar content being viewed by others

References

D. H. Xu, G. Duan, and W. L. Johnson, “Unusual glass-forming ability of bulk amorphous alloys based on ordinary metal copper,” Phys. Rev. Lett., 92, No. 24, 245504-1–245504-4 (2004).

J. Saida, M. Matsushita, C. Li, and A. Inoue, “Formation of icosahedral quasicrystalline phase in Zr70Ni10M20 (M = Pd, Au, Pt) ternary metallic glasses,” Appl. Phys. Lett., 76, No. 24, 3558–3560 (2000).

S. Yi and D. H. Kim, “Stability and phase transformations of icosahedral phase in a 41.5Zr41.5Ti17Ni alloy,” J. Mater. Res., 15, 892–897 (2000).

B. S. Murty, D. H. Ping, K. Hono, and A. Inoue, “Direct evidence for oxygen stabilization of icosahedral phase during crystallization of Zr65Cu27.5Al7.5 metallic glass,” Appl. Phys. Lett., 76, No. 1, 55–57 (2000).

S. C. Tjong and Z. Y. Ma, “Microstructural and mechanical characteristics of in situ metal matrix composites,” Mater. Sci. Eng., R: Reports, 29, Nos. 3–4, 49–113 (2000).

J. Ram, M. Campo, and A. Urena, “Sol-gel coatings to improve processing of aluminium matrix SiC reinforced composite materials,” J. Mater. Res., 19, No. 7, 2109–2116 (2004).

M. H. Lee, J. H. Kim, J. S. Park, J. C. Kim, W. T. Kim, and D. H. Kim, “Fabrication of Ni-Nb-Ta metallic glass reinforced Al-based alloy matrix composites by infiltration casting process,” Scripta Mater., 50, No. 11, 1367–1371 (2004).

Yu P., Zhang L. C., Zhang W. Y., et al., “Interfacial reaction during the fabrication of Ni60Nb40 metallic glass particles-reinforced Al-based MMCs,” Mater. Sci. Eng., A., 444, Nos. 1–2, 206–213 (2007).

M. H. Lee, J. H. Kim, J. S. Park, W. T. Kim, and D. H. Kim, “Development of Ni-Nb-Ta metallic glass particle reinforced Al-based matrix composites,” Mater. Sci. Forum., 475, No. 5, 3427–3430 (2005).

P. Yu, K. B. Kim, J. Das, F. Baier, W. Xu, and J. Eckert, “Fabrication and mechanical properties of Ni-Nb metallic glass particle-reinforced Al-based metal matrix composite,” Scripta Mater., 54, No. 8, 1445–1450 (2006).

Z. Zhang, B. Q. Han, D. Witkin, et al., “Synthesis of nanocrystalline aluminum matrix composites reinforced with in situ devitrified Al-Ni-La amorphous particles,” Scripta Mater., 54, No. 5, 869–874 (2006).

M. T. Stawovy and A. O. Aning, “Processing of amorphous Fe-W reinforced Fe matrix composites,” Mater. Sci. Eng., A, 256, Nos. 1–2, 138–143 (1998).

J. Wang, X. Li, H. Yan, et al., “Research of energy deposition caused by microexplosive welding in explosive consolidation of metal powders,” Rare Metal Mater., Eng., 35, No. 7, 1039–1044 (2006).

M. A. Meyers and S. L. Wang, “An improved method for shock consolidation of powders,” Acta Metall., 36, No. 24, 925–936 (1988).

R. Prummer, “Explosive compaction of metallic glass powders,” Mater. Sci. Eng., 98, 461–463 (1988).

Author information

Authors and Affiliations

Additional information

__________

Translated from Fizika Goreniya i Vzryva, Vol. 45, No. 2, pp. 137–142, March–April, 2009.

Rights and permissions

About this article

Cite this article

Zhang, XL., Wang, JX., Sun, YX. et al. Metallic glass particle reinforced Al-based and (Al-Ni)-based metal matrix composites. Combust Explos Shock Waves 45, 230–235 (2009). https://doi.org/10.1007/s10573-009-0030-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10573-009-0030-8