Abstract

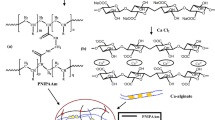

Hydrogel-born fire resistance materials have attracted great attention due to their flame retardance and environmental friendliness. In this work, a facile strategy is presented to prepare a novel hydrogel–cotton fabric laminate with excellent thermal insulation and fire-retarding performance. The hydrogel–fabric laminates exhibited outstanding flame retardant behavior. The flame-retardant mechanism of this system was mainly due to the absorption of a large amount of energy as the water is heated and evaporated in the hydrogel layer. To increase the water retention capacity of the fire-resistant hydrogel, highly hydratable salt (CaCl2) was incorporated into the fire-resistant composite hydrogel composed of poly(N-isopropylacrylamide) (PNIPAAm)/sodium alginate (SA) to prolong water retention time. Here in this work, we aimed to investigate the effect of CaCl2 concentration on water retention capacity, fire-resistant and thermal insulating properties of hydrogel–cotton fabric laminates. Results indicated that the presence of hydratable salt successfully prolonged the water retention time and provided superior fire retardance property over traditional hydrogel. In additional, infrared imaging and vertical flammability test results confirmed that hydrogel–fabric laminates were capable of sustaining 1200 °C for 30 min without the cotton fabric layer burning, whereas natural cotton fabric was completely burned after 12 s. Finally, the hydrogel–cotton fabric laminates exhibited remarkable antibacterial activity against Staphylococcus aureus and Escherichia coli due to incorporated silver nanoparticles in hydrogels, and the bacteriostatic rates both exceeded 96%. The preparation of this hydrogel-born fire resistance materials is facile and can extended the period of protective time as fire resistant clothing for the firefighters.

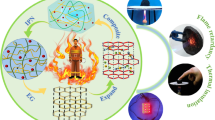

Graphic abstract

Similar content being viewed by others

References

Bai YY, Chen BH, Xiang F, Zhou JX, Wang H, Suo ZG (2014) Transparent hydrogel with enhanced water retention capacity by introducing highly hydratable salt. Appl Phys Lett 105(15):151903. https://doi.org/10.1063/1.4898189

Cai CY, Wei ZC, Huang YZ, Ding CF, Wang P, Song JY (2020) Ultralight programmable bioinspired aerogels with an integrated multifunctional surface for self-cleaning, oil absorption, and thermal insulation via coassembly. ACS Appl Mater Interfaces 12(9):11273–11286. https://doi.org/10.1021/acsami.0c00308

Chen JY, Xie HL, Lai XJ, Li HQ, Gao JF, Zeng XR (2020) An ultrasensitive fire-warning chitosan/montmorillonite/carbon nanotube composite aerogel with high fire-resistance. Chem Eng J 399:125729. https://doi.org/10.1016/j.cej.2020.125729

Cui XF, Zheng WJ, Zou W, Liu XY, Yang H, Yan J, Gao Y (2019) Water-retaining, tough and self-healing hydrogels and their uses as fire-resistant materials. Polym Chem-UK 10(37):5151–5158. https://doi.org/10.1039/c9py01015g

Eklund A, Zhang H, Zeng H, Priimagi A, Ikkala O (2020) Fast switching of bright whiteness in channeled hydrogel networks. Adv Funct Mater 30(28):2000754. https://doi.org/10.1002/adfm.202000754

Guo WW, Wang X, Huang JL, Zhou YF, Cai W, Wang JL, Song L, Hu Y (2020) Construction of durable flame-retardant and robust superhydrophobic coatings on cotton fabrics for water–oil separation application. Chem Eng J 398:125661. https://doi.org/10.1016/j.cej.2020.125661

Homaeigohar S, Boccaccini AR (2020) Antibacterial biohybrid nanofibers for wound dressings. Acta Biomater 107:25–49. https://doi.org/10.1016/j.actbio.2020.02.022

Illeperuma WRK, Rothemund P, Suo ZG, Vlassak JJ (2016) Fire-resistant hydrogel–fabric laminates: a simple concept that may save lives. ACS Appl Mater Interfaces 8(3):2071–2077. https://doi.org/10.1021/acsami.5b10538

Jiang ZW, Du GL (2020) Preparation and Characterization of chitosan grafting hydrogel for mine-fire fighting. ACS Omega 5(5):2303–2309. https://doi.org/10.1021/acsomega.9b03551

Li SS, Lin XH, Li ZG, Ren XH (2019) Hybrid organic-inorganic hydrophobic and intumescent flame-retardant coating for cotton fabrics. Compos Commun 14:15–20. https://doi.org/10.1016/j.coco.2019.05.005

Li P, Wang B, Liu YY, Xu YJ, Jiang ZM, Dong CH, Zhang L, Liu Y, Zhu P (2020a) Fully bio-based coating from chitosan and phytate for fire-safety and antibacterial cotton fabrics. Carbohyd Polym 237:116173. https://doi.org/10.1016/j.carbpol.2020.116173

Li YS, Hu XM, Cheng WM, Shao Z, Xue D, Zhao YY, Lu W (2020b) A novel high-toughness, organic/inorganic double-network fire-retardant gel for coal-seam with high ground temperature. Fuel 263:116779. https://doi.org/10.1016/j.fuel.2019.116779

Lin J, Chen XY, Chen CY, Hu JT, Zhou CL, Cai XF, Wang W, Zheng C, Zhang PP, Cheng J, Guo ZH, Liu H (2018) Durably antibacterial and bacterially antiadhesive cotton fabrics coated by cationic fluorinated polymers. ACS Appl Mater Interfaces 10(7):6124–6136. https://doi.org/10.1021/acsami.7b16235

Liu Q, Yang S, Ren J, Ling SJ (2020a) Flame-retardant and sustainable silk ionotronic skin for fire alarm systems. ACS Mater Lett 2(7):712–720. https://doi.org/10.1021/acsmaterialslett.0c00062

Liu SD, Wan CY, Chen Y, Chen R, Zhang FX, Zhang GX (2020b) A novel high-molecular-weight flame retardant for cotton fabrics. Cellulose 27(6):3501–3515. https://doi.org/10.1007/s10570-020-03020-0

Mou CL, Ju XJ, Zhang L, Xie R, Wang W, Deng NN, Wei J, Chen QM, Chu LY (2014) Monodisperse and fast-responsive poly(N-isopropylacrylamide) microgels with open-celled porous structure. Langmuir 30(5):1455–1464. https://doi.org/10.1021/la4046379

Mykhalichko B, Lavrenyuk H, Mykhalichko O (2019) New water-based fire extinguishant: Elaboration, bench-scale tests, and flame extinguishment efficiency determination by cupric chloride aqueous solutions. Fire Saf J 105:188–195. https://doi.org/10.1016/j.firesaf.2019.03.005

Qin HB, Fang KJ, Ren YF, Zhang K, Zhang LY, Zhang XY (2020) Insights into influences of dye hydrophobicity on cleanliness and resolution of fabric ink jet printing. ACS Sustain Chem Eng 8:17291–17298. https://doi.org/10.1021/acssuschemeng.0c06447

Ren XF, Hu XM, Xue D, Li YS, Shao Z, Dong H, Cheng WM, Zhao YY, Xin L, Lu W (2019) Novel sodium silicate/polymer composite gels for the prevention of spontaneous combustion of coal. J Hazard Mater 371:643–654. https://doi.org/10.1016/j.jhazmat.2019.03.041

Ren YF, Fu RR, Fang KJ, Xie RY, Hao LY, Chen WC, Shi Z (2021) Clean dyeing of acrylic fabric by sustainable red bacterial pigment based on nano-suspension system. J Clean Prod 281:125295. https://doi.org/10.1016/j.jclepro.2020.125295

Rosace G, Castellano A, Trovato V, Iacono G, Malucell G (2018) Thermal and flame retardant behavior of cotton fabrics treated with a novel nitrogen-containing carboxyl-functionalized organophosphorus system. Carbohydr Polym 196:348–358. https://doi.org/10.1016/j.carbpol.2018.05.012

Sun XF, Zeng QH, Wang HH, Hao YW (2019) Preparation and swelling behavior of pH/temperature responsive semi-IPN hydrogel based on carboxymethyl xylan and poly(N-isopropyl acrylamide). Cellulose 26(3):1909–1922. https://doi.org/10.1007/s10570-018-2180-x

Wang ZF, Li HL, Tang ZJ, Liu ZX, Ruan ZH, Ma LT, Yang Q, Wang DH, Zhi CY (2018) Hydrogel electrolytes for flexible aqueous energy storage devices. Adv Funct Mater 28(48):1804560. https://doi.org/10.1002/adfm.201804560

Wang L, Zhang XH, Yang K, Fu YV, Xu TS, Li SL, Zhang DW, Wang LN, Lee CS (2019) A novel double-crosslinking-double-network design for injectable hydrogels with enhanced tissue adhesion and antibacterial capability for wound treatment. Adv Funct Mater 30(1):1904156. https://doi.org/10.1002/adfm.201904156

Wang B, Li P, Xu YJ, Jiang ZM, Dong CH, Liu Y, Zhu P (2020) Bio-based, nontoxic and flame-retardant cotton/alginate blended fibres as filling materials: thermal degradation properties, flammability and flame-retardant mechanism. Compos Part B Eng 194:108038. https://doi.org/10.1016/j.compositesb.2020.108038

Xie Y, Chen SQ, Zhang X, Shi ZQ, Wei ZW, Bao JX, Zhao WF, Zhao CS (2019) Engineering of tannic acid inspired antifouling and antibacterial membranes through co-deposition of zwitterionic polymers and Ag nanoparticles. Ind Eng Chem Res 58(27):11689–11697. https://doi.org/10.1021/acs.iecr.9b00224

Xie RY, Fang KJ, Liu Y, Chen WC, Fan JN, Wang XW, Ren YF, Song YW (2020) Z-scheme In2O3/WO3 heterogeneous photocatalysts with enhanced visible-light-driven photocatalytic activity toward degradation of organic dyes. J Mater Sci 55(26):11919–11937. https://doi.org/10.1007/s10853-020-04863-5

Xu QB, Shen LW, Duan PP, Zhang L, Fu FY, Liu XD (2020) Superhydrophobic cotton fabric with excellent healability fabricated by the “grafting to” method using a diblock copolymer mist. Chem Eng J 379:122401. https://doi.org/10.1016/j.cej.2019.122401

Yu ZC, Suryawanshi A, He HL, Liu JR, Li YQ, Lin XB, Sun ZH (2020) Preparation and characterization of fire-resistant PNIPAAm/SA/AgNP thermosensitive network hydrogels and laminated cotton fabric used in firefighter protective clothing. Cellulose 27(9):5391–5406. https://doi.org/10.1007/s10570-020-03146-1

Zeng HC, Yang JS, Han SY (2016) The synthesis and characteristics of sodium alginate/graphene oxide composite films crosslinked with multivalent cations. Appl Polym Sci 133(27):43616. https://doi.org/10.1002/app.43616

Zhang QF, Zhao LY, Wang J, Wang S, Liu YX, Liu XF (2020) High-strength and high-toughness sodium alginate/polyacrylamide double physically crosslinked network hydrogel with superior self-healing and self-recovery properties prepared by a one-pot method. Colloid Surf A 589:124402. https://doi.org/10.1016/j.colsurfa.2019.124402

Acknowledgments

The authors acknowledge financial support from Opening Project of Key Laboratory of High Performance fibers and products (Ministry of Education), Opening Project of Key Laboratory of Clean Dyeing and Finishing Technology of Zhejiang Province (Grant Number QJRZ1904), and Opening Project of Hubei Key Laboratory of Biomass Fibers and Eco-Dyeing & Finishing (Grant Number STRZ2020005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Research involving human participants and/or animals

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Informed consent was obtained from all individual participants included in the study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yu, Z., Liu, J., Suryawanshi, A. et al. Thermal insulating and fire-retarding behavior of treated cotton fabrics with a novel high water-retaining hydrogel used in thermal protective clothing. Cellulose 28, 2581–2597 (2021). https://doi.org/10.1007/s10570-021-03696-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-03696-y