Abstract

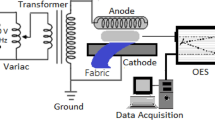

This paper describes the He non-thermal plasma treatment of liquid impregnated cotton fabrics. The cotton fabrics were soaked in either H2O, D2O or ethanol after which they were placed in an atmospheric pressure parallel-plate DBD reactor. The influence of the used liquid in combination with the plasma exposure time was studied using OES, FTIR, XPS and SEM. The addition of (deuterated) water was found to aid more efficiently in the incorporation of polar functional groups onto the cotton surface in comparison to a pure He plasma treatment. The presence of H and OH species in the discharge also caused extensive etching of the surface, which led to the formation of microcraters. The impregnation with ethanol was responsible for the formation of a plasma-based thin film on top of the cotton substrate, which was characterized by a high content of C–C bonds and a smooth surface morphology. These results show that the soaking of cotton fabric prior to plasma exposure can help to more effectively alter its surface properties compared to a dry plasma treatment.

Similar content being viewed by others

References

Acsente T, Ionita MD, Teodorescu M, Marascu V, Dinescu G (2016) Surface modification of polymethylmethacrylate foils using an atmospheric pressure plasma jet in presence of water vapors. Thin Solid Films 614:25–30. https://doi.org/10.1016/j.tsf.2015.12.037

Aileni RM, Albici S, Chiriac L, Subtirica A, Dinca LC (2019) Aspects of the hydrophobic effect sustainability obtained in plasma for cotton fabrics. Ind Textila 70:223–228. https://doi.org/10.35530/IT.070.03.1475

Ananth NB, Mark JK (2008) Repetitively pulsed atmospheric pressure discharge treatment of rough polymer surfaces: II. Treatment of micro-beads in He/NH3/H2O and He/O2/H2O mixtures. Plasma Sources Sci Technol 17:035025. https://doi.org/10.1088/0963-0252/17/3/035025

Asandulesa M, Topala I, Dumitrascu N (2010) Effect of helium DBD plasma treatment on the surface of wood samples. Holzforschung 64:223–227. https://doi.org/10.1515/hf.2010.025

Belhadj H, Hakki A, Robertson PK, Bahnemann DW (2015) In situ ATR-FTIR study of H2O and D2O adsorption on TiO2 under UV irradiation. Phys Chem Chem Phys 17:22940–22946. https://doi.org/10.1039/C5CP03947A

Bierstedt A, Panne U, Rurack K, Riedel J (2015) Characterization of two modes in a dielectric barrier discharge probe by optical emission spectroscopy and time-of-flight mass spectrometry. J Anal At Spectrom 30:2496–2506. https://doi.org/10.1039/c5ja00332f

Brisset J-L, Pawlat J (2016) Chemical effects of air plasma species on aqueous solutes in direct and delayed exposure modes: discharge, post-discharge and plasma activated water. Plasma Chem Plasma Process 36:355–381. https://doi.org/10.1007/s11090-015-9653-6

Castle JE (1984) Practical surface analysis by Auger and X-ray photoelectron spectroscopy. D. Briggs and M. P. Seah (Editors). John Wiley and Sons Ltd, Chichester, 1983, 533 pp. Surf Interface Anal 6:302. https://doi.org/10.1002/sia.740060611

Chung C, Lee M, Choe EK (2004) Characterization of cotton fabric scouring by FT-IR ATR spectroscopy. Carbohydr Polym 58:417–420. https://doi.org/10.1016/j.carbpol.2004.08.005

Cools P, De Geyter N, Morent R (2015) Plasma modified textiles for biomedical applications. Intech. https://doi.org/10.5772/59770

De Geyter N, Sarani A, Jacobs T, Nikiforov AY, Desmet T, Dubruel P (2013) Surface modification of poly-epsilon-caprolactone with an atmospheric pressure plasma jet. Plasma Chem Plasma Process 33:165–175. https://doi.org/10.1007/s11090-012-9419-3

Friedrich JF, Mix R, Schulze RD, Meyer-Plath A, Joshi R, Wettmarshausen S (2008) New plasma techniques for polymer surface modification with monotype functional groups. Plasma Process Polym 5:407–423. https://doi.org/10.1002/ppap.200700145

Garside P, Wyeth P (2003) Identification of cellulosic fibres by FTIR spectroscopy—thread and single fibre analysis by attenuated total reflectance. Stud Conserv 48:269–275. https://doi.org/10.1179/sic.2003.48.4.269

Gorbanev Y, O’Connell D, Chechik V (2016) Non-thermal plasma in contact with water: the origin of species. Chem Eur J 22:3496–3505. https://doi.org/10.1002/chem.201503771

Gorjanc M, Bukošek V, Gorenšek M, Mozetič M (2010) CF4 plasma and silver functionalized cotton. Text Res J 80:2204–2213. https://doi.org/10.1177/0040517510376268

Haji A (2017) Improved natural dyeing of cotton by plasma treatment and chitosan coating; optimization by response surface methodology. Cell Chem Technol 51:975–982

Haji A (2019) Dyeing of cotton fabric with natural dyes improved by mordants and plasma treatment. Prog Color Color Coat 12:191–201

Haji A, Barani H, Qavamnia SS (2013) In situ synthesis of silver nanoparticles onto cotton fibres modified with plasma treatment and acrylic acid grafting. Micro Nano Lett 8:315–318

Haji A, Qavamnia SS, Bizhaem FK (2016) Salt free neutral dyeing of cotton with anionic dyes using plasma and chitosan treatments. Ind Text 67:109–113

Holländer A, Wilken R, Behnisch J (1999) Subsurface chemistry in the plasma treatment of polymers. Surf Coat Technol 116:788–791. https://doi.org/10.1016/S0257-8972(99)00297-2

Hsieh Y-L, Thompson J, Miller A (1996) Water wetting and retention of cotton assemblies as affected by alkaline and bleaching treatments. Text Res J 66:456–464. https://doi.org/10.1177/004051759606600707

Ikawa S, Kitano K, Hamaguchi S (2010) Effects of pH on bacterial inactivation in aqueous solutions due to low-temperature atmospheric pressure plasma application. Plasma Process Polym 7:33–42. https://doi.org/10.1002/ppap.200900090

Ikegami T, Nakanishi F, Uchiyama M, Ebihara K (2004) Optical measurement in carbon nanotubes formation by pulsed laser ablation. Thin Solid Films 457:7–11. https://doi.org/10.1016/j.tsf.2003.12.033

Joshi R, Schulze RD, Meyer-Plath A, Friedrich JF (2008) Selective surface modification of poly(propylene) with OH and COOH groups using liquid-plasma systems. Plasma Process Polym 5:695–707. https://doi.org/10.1002/ppap.200700175

Joshi R, Friedrich JF, Wagner M (2009a) Study of carboxylic functionalization of polypropylene surface using the underwater plasma technique. Eur Phys J D 54:249–258. https://doi.org/10.1140/epjd/e2009-00088-6

Joshi R, Schulze RD, Meyer-Plath A, Wagner MH, Friedrich JF (2009b) Selective surface modification of polypropylene using underwater plasma technique or underwater capillary discharge. Plasma Process Polym 6:S218–S222. https://doi.org/10.1002/ppap.200930601

Joshi R, Friedrich J, Krishna-Subramanian S (2013) Surface modification of ultra-high molecular weight polyethylene membranes using underwater plasma polymerization. Plasma Chem Plasma Process 33:921–940. https://doi.org/10.1007/s11090-013-9476-2

Jovančić P, Vílchez A, Molina R (2016) Synthesis of thermo-sensitive hydrogels from free radical copolymerization of NIPAAm with MBA initiated by atmospheric plasma treatment. Plasma Process Polym 13:752–760. https://doi.org/10.1002/ppap.201500194

Karahan H, Özdoğan E (2008) Improvements of surface functionality of cotton fibers by atmospheric plasma treatment. Fiber Polym 9:21–26

Khlyustova A, Galmiz O, Zahoran M, Brablec A, Černak M (2015) Underwater discharge plasma-induced coating of poly(acrylic acid) on polypropylene fiber. J Mater Sci 50:3504–3509. https://doi.org/10.1007/s10853-015-8913-4

Kolarova K, Vosmanska V, Rimpelova S, Svorcik V (2013) Effect of plasma treatment on cellulose fiber. Cellulose 20:953–961. https://doi.org/10.1007/s10570-013-9863-0

Liu DX, Bruggeman P, Iza F, Rong MZ, Kong MG (2010) Global model of low-temperature atmospheric-pressure He + H2O plasmas. Plasma Sources Sci Technol 19:025018. https://doi.org/10.1088/0963-0252/19/2/025018

Liu H, Wang Y, Bowman JM (2016) Quantum local monomer IR spectrum of liquid D2O at 300 K from 0 to 4000 cm−1 is in near-quantitative agreement with experiment. J. Phys. Chem. B 120:2824–2828. https://doi.org/10.1021/acs.jpcb.6b01722

Mihailović D et al (2011) Functionalization of cotton fabrics with corona/air RF plasma and colloidal TiO2 nanoparticles. Cellulose 18:811–825. https://doi.org/10.1007/s10570-011-9510-6

Molina R, Ligero C, Jovančić P, Bertran E (2013a) In situ polymerization of aqueous solutions of NIPAAm initiated by atmospheric plasma treatment. Plasma Process Polym 10:506–516. https://doi.org/10.1002/ppap.201200121

Molina R, Sole I, Vilchez A, Bertran E, Solans C, Esquena J (2013b) Surface functionalization of macroporous polymeric materials by treatment with air low temperature. Plasma J Nanosci Nanotechnol 13:2819–2825. https://doi.org/10.1166/jnn.2013.7369

Molina R, Gómez M, Kan C-W, Bertran E (2014) Hydrophilic–oleophobic coatings on cellulosic materials by plasma assisted polymerization in liquid phase and fluorosurfactant complexation. Cellulose 21:729–739. https://doi.org/10.1007/s10570-013-0131-0

Molina R, Teixidó JM, Kan C-W, Jovančić P (2017) Hydrophobic coatings on cotton obtained by in situ plasma polymerization of a fluorinated monomer in ethanol solutions. ACS Appl Mater Interfaces 9:5513–5521. https://doi.org/10.1021/acsami.6b15812

Morent R, De Geyter N, Leys C, Gengernbre L, Payen E (2008) Comparison between XPS- and FTIR-analysis of plasma-treated polypropylene film surfaces. Surf Interface Anal 40:597–600. https://doi.org/10.1002/Sia.2619

Patino A, Canal C, Rodríguez C, Caballero G, Navarro A, Canal JM (2011) Surface and bulk cotton fibre modifications: plasma and cationization. Influence on dyeing with reactive dye. Cellulose 18:1073–1083. https://doi.org/10.1007/s10570-011-9554-7

Rajasekaran P, Muthuraman B (2019) Effect of plasma pre-treatment on the conductivity of polypyrrole-coated cotton fabric. Fiber Polym 20:2114–2119. https://doi.org/10.1007/s12221-019-1177-x

Sun D, Stylios G (2004) Effect of low temperature plasma treatment on the scouring and dyeing of natural fabrics. Text Res J 74:751–756. https://doi.org/10.1177/004051750407400901

Tani A, Ono Y, Fukui S, Ikawa S, Kitano K (2012) Free radicals induced in aqueous solution by non-contact atmospheric-pressure cold plasma. Appl Phys Lett 100:254103. https://doi.org/10.1063/1.4729889

Tatoulian M, Arefi-Khonsari F, Mabille-Rouger I, Amouroux J, Gheorgiu M, Bouchier D (1995) Role of helium plasma pretreatment in the stability of the wettability, adhesion, and mechanical properties of ammonia plasma-treated polymers. Application to the Al-polypropylene system. J Adhes Sci Technol 9:923–934. https://doi.org/10.1163/156856195X00798

Topalovic T, Nierstrasz VA, Bautista L, Jocic D, Navarro A, Warmoeskerken M (2007) Analysis of the effects of catalytic bleaching on cotton. Cellulose 14:385–400. https://doi.org/10.1007/s10570-007-9120-5

Van Deynse A, De Geyter N, Leys C, Morent R (2014) Influence of water vapor addition on the surface modification of polyethylene in an argon dielectric barrier discharge. Plasma Process Polym 11:117–125. https://doi.org/10.1002/ppap.201300088

Van Deynse A, Morent R, Leys C, De Geyter N (2017) Influence of ethanol vapor addition on the surface modification of polyethylene in a dielectric barrier discharge. Appl Surf Sci 419:847–859. https://doi.org/10.1016/j.apsusc.2017.05.111

Wang C, Liu Y, Xu H, Ren Y, Qiu Y (2008) Influence of atmospheric pressure plasma treatment time on penetration depth of surface modification into fabric. Appl Surf Sci 254:2499–2505. https://doi.org/10.1016/j.apsusc.2007.09.074

Wang X et al (2019) The application of atmospheric plasma for cotton fabric desizing. Fiber Polym 20:2334–2341. https://doi.org/10.1007/s12221-019-9330-0

Yanguas-Gil A, Hueso JL, Cotrino J, Caballero A, Gonzalez-Elipe AR (2004) Reforming of ethanol in a microwave surface-wave plasma discharge. Appl Phys Lett 85:4004–4006. https://doi.org/10.1063/1.1808875

Yasuda H, Hirotsu T (1978) Critical evaluation of conditions of plasma polymerization. J Polym Sci Pol Chem 16:743–759. https://doi.org/10.1002/pol.1978.170160403

Acknowledgments

This work received financial support from the MAT2016-79866-R project (AEI/FEDER, UE). P. Cools would like to acknowledge the Special Research Fund of Ghent University for funding his post-doctoral mandate (BOF17/PDO/023). The authors would also like to thank the contribution of the scanning electron microscopy service of the Institute of Marine Sciences (ICM-CSIC).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Molina, R., Bitar, R., Cools, P. et al. Effect of liquid impregnation on DBD atmospheric pressure plasma treatment of cotton. Cellulose 27, 7847–7859 (2020). https://doi.org/10.1007/s10570-020-03306-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03306-3