Abstract

Lignocellulose nanofibrils (LCNFs) are nano-objects produced in aqueous suspension by industrially adaptable methods, with a high yield, low production cost and the potential to replace or complement delignified cellulose nanofibrils in their current applications. To this end, it is necessary to understand how their constituents affect the production and characteristics of the final product. This review explores the most recent results on the effect of the residual amount of lignin and hemicelluloses on the properties of LCNF suspensions. In the current literature, there is a consensus on hemicelluloses, a larger amount of which favors the mechanical fibrillation process, with mannans providing the greatest benefits. Meanwhile, there is no consensus on the effect of residual lignin on mechanical fibrillation, since it can act as an antioxidant, which promotes fibrillation, or as a cementing agent, which hinders fibrillation and, therefore, the production of LCNFs.

(adapted from Espinosa et al. 2017a)

Similar content being viewed by others

References

Abe K, Iwamoto S, Yano H (2007) Obtaining cellulose nanofibers with a uniform width of 15 nm from wood. Biomacromolecules 8(10):3276–3278

Albornoz-Palma G, Betancourt F, Mendonça RT, Chinga-Carrasco G, Pereira M (2020) Relationship between rheological and morphological characteristics of cellulose nanofibrils in dilute dispersions. Carbohydr Polym 230:115588

Alemdar A, Sain M (2008) Isolation and characterization of nanofibers from agricultural residues—wheat straw and soy hulls. Bioresour Technol 99(6):1664–1671

Alila S, Besbes I, Vilar MR, Mutjé P, Boufi S (2013) Non-woody plants as raw materials for production of microfibrillated cellulose (MFC): a comparative study. Ind Crops Prod 41:250–259

Besbes I, Vilar MR, Boufi S (2011) Nanofibrillated cellulose from alfa, eucalyptus and pine fibres: preparation, characteristics and reinforcing potential. Carbohydr Polym 86(3):1198–1206

Bian H et al (2019) Comparison of mixed enzymatic pretreatment and post-treatment for enhancing the cellulose nanofibrillation efficiency. Bioresour Technol 293:122171

Bian H, Chen L, Dai H, Zhu JY (2017) Integrated production of lignin containing cellulose nanocrystals (LCNC) and nanofibrils (LCNF) using an easily recyclable di-carboxylic acid. Carbohydr Poly 167:167–176

Bian H, Chen L, Gleisner R, Dai H, Zhu JY (2017b) Producing wood-based nanomaterials by rapid fractionation of wood at 80 C using a recyclable acid hydrotrope. Green Chem 19(14):3370–3379

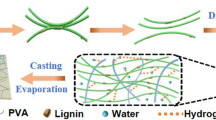

Bian H, Wei L, Lin C, Ma Q, Dai H, Zhu JY (2018) Lignin-containing cellulose nanofibril-reinforced polyvinyl alcohol hydrogels. ACS Sustain Chem Eng 6(4):4821–4828

Borrega M, Orelma H (2019) Cellulose Nanofibril (CNF) Films and xylan from hot water extracted birch kraft pulps. Appl Sci 9(16):3436

Carpita NC, Gibeaut DM (1993) Structural models of primary cell walls in flowering plants: consistency of molecular structure with the physical properties of the walls during growth. Plant J 3(1):1–30

Chaker A, Alila S, Mutjé P, Vilar MR, Boufi S (2013) Key role of the hemicellulose content and the cell morphology on the nanofibrillation effectiveness of cellulose pulps. Cellulose 20(6):2863–2875

Chen Y, Fan D, Han Y, Lyu S, Lu Y, Li G, Jiang F, Wang S (2018) Effect of high residual lignin on the properties of cellulose nanofibrils/films. Cellulose 25(11):6421–6431

Chinga-Carrasco G (2011) Cellulose fibres, nanofibrils and microfibrils: the morphological sequence of MFC components from a plant physiology and fibre technology point of view. Nanoscale Res Lett 6(1):417

de Carvalho DM, Moser C, Lindström ME, Sevastyanova O (2019) Impact of the chemical composition of cellulosic materials on the nanofibrillation process and nanopaper properties. Ind Crops Prod 127:203–211

Delgado-Aguilar M (2015) Nanotecnología en el sector papelero: mejoras en calidad y permanencia de las fibras de alto rendimiento y secundarias en una economía circular mediante el uso de nanofibras y el refino enzimático. Tesis doctoral. Universitat de Girona, España

Delgado-Aguilar M, González I, Tarrés Q, Pèlach M, Alcalà M, Mutjé P (2016) The key role of lignin in the production of low-cost lignocellulosic nanofibres for papermaking applications. Ind Crops Prod 86:295–300

Dimic-Misic K, Maloney T, Gane P (2018) Effect of fibril length, aspect ratio and surface charge on ultralow shear-induced structuring in micro and nanofibrillated cellulose aqueous suspensions. Cellulose 25(1):117–136

Diop CIK, Tajvidi M, Bilodeau MA, Bousfield DW, Hunt JF (2017) Isolation of lignocellulose nanofibrils (LCNF) and application as adhesive replacement in wood composites: example of fiberboard. Cellulose 24(7):3037–3050

Dizhbite T, Telysheva G, Jurkjane V, Viesturs U (2004) Characterization of the radical scavenging activity of lignins––natural antioxidants. Biores Technol 95(3):309–317

Dufresne A (2013) Nanocellulose: from nature to high performance tailored materials. Walter de Gruyter, Berlin

Dullaert K, Mewis J (2005) Stress jumps on weakly flocculated dispersions: steady state and transient results. J Colloid Interface Sci 287(2):542–551

Ek M, Gellerstedt G, Henriksson G (2009) Wood chemistry and biotechnology, vol 1. Walter de Gruyter, Berlin

Eronen P, Österberg M, Heikkinen S, Tenkanen M, Laine J (2011) Interactions of structurally different hemicelluloses with nanofibrillar cellulose. Carbohydr Polym 86(3):1281–1290

Espinosa E, Sánchez R, González Z, Domínguez-Robles J, Ferrari B, Rodríguez A (2017a) Rapidly growing vegetables as new sources for lignocellulose nanofibre isolation: physicochemical, thermal and rheological characterisation. Carbohydr Polym 175:27–37

Espinosa E, Sánchez R, Otero R, Domínguez-Robles J, Rodríguez A (2017b) A comparative study of the suitability of different cereal straws for lignocellulose nanofibers isolation. Int J Biol Macromol 103:990–999

Fengel D, Wegener G (1984) Wood: chemistry, ultrastructure, reactions, vol 1. Walter de Gruyter, Berlin, pp 1960–1982

Ferrer A, Quintana E, Filpponen I, Solala I, Vidal T, Rodríguez A, Laine J, Rojas OJ (2012) Effect of residual lignin and heteropolysaccharides in nanofibrillar cellulose and nanopaper from wood fibers. Cellulose 19(6):2179–2193

Foster EJ, Moon RJ, Agarwal UP, Bortner MJ, Bras J, Camarero-Espinosa S, Chan K, Clift M, Cranton E, Eichhorn S, Fox D, Hamad W, Heux K, Jean B, Korey M, Nieh K, Reid M, Renneckar S, Roberts R, Shathin J, Simonsen J, Stinson-Bagby K, Wanasekara N, Youngblood J (2018) Current characterization methods for cellulose nanomaterials. Chem Soc Rev 47(8):2609–2679

García A, Alriols MG, Spigno G, Labidi J (2012) Lignin as natural radical scavenger. Effect of the obtaining and purification processes on the antioxidant behaviour of lignin. Biochem Eng J 67:173–185

Gregorova A, Košíková B, Staško A (2007) Radical scavenging capacity of lignin and its effect on processing stabilization of virgin and recycled polypropylene. J Appl Polym Sci 106(3):1626–1631

Grüneberger F, Künniger T, Zimmermann T, Arnold M (2014) Rheology of nanofibrillated cellulose/acrylate systems for coating applications. Cellulose 21(3):1313–1326

Gu L, Jiang B, Song J, Jin Y, Xiao H (2019) Effect of lignin on performance of lignocellulose nanofibrils for durable superhydrophobic surface. Cellulose 26(2):933–944

He M, Yang G, Chen J, Ji X, Wang Q (2018) Production and characterization of cellulose nanofibrils from different chemical and mechanical pulps. J Wood Chem Technol 38(2):149–158

Herzele S, Veigel S, Liebner F, Zimmermann T, Gindl-Altmutter W (2016) Reinforcement of polycaprolactone with microfibrillated lignocellulose. Ind Crops Prod 93:302–308

Heyn A (1969) The elementary fibril and supermolecular structure of cellulose in soft wood fiber. J Ultrastruct Res 26:52–68

Hoeger IC, Filpponen I, Martin-Sampedro R, Johansson LS, Österberg M, Laine J, Rojas OJ (2012) Bicomponent lignocellulose thin films to study the role of surface lignin in cellulolytic reactions. Biomacromolecules 13(10):3228–3240

Hoeger IC, Nair SS, Ragauskas AJ, Deng Y, Rojas OJ, Zhu JY (2013) Mechanical deconstruction of lignocellulose cell walls and their enzymatic saccharification. Cellulose 20(2):807–818

Horseman T, Tajvidi M, Diop CI, Gardner DJ (2017) Preparation and property assessment of neat lignocellulose nanofibrils (LCNF) and their composite films. Cellulose 24(6):2455–2468

Hult E-L, Larsson PT, Iversen T (2001) Cellulose fibril aggregation an inherent property of kraft pulps. Polymer 42(8):3309–3314

Iotti M, Gregersen ØW, Moe S, Lenes M (2011) Rheological studies of microfibrillar cellulose water dispersions. J Polym Environ 19(1):137–145

ISO ISO/TS (2017) 20477:2017 Nanotechnologies—Standard terms and their definition for cellulose nanomaterial. ISO, Geneva

Iwamoto S, Nakagaito AN, Yano H, Nogi M (2005) Optically transparent composites reinforced with plant fiber-based nanofibers. Appl Phys A Mater Sci Process 81(6):1109–1112

Iwamoto S, Nakagaito AN, Yano H (2007) Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appl Phys A 89(2):461–466

Iwamoto S, Abe K, Yano H (2008) The effect of hemicelluloses on wood pulp nanofibrillation and nanofiber network characteristics. Biomacromolecules 9(3):1022–1026

Iwamoto S, Lee SH, Endo T (2014) Relationship between aspect ratio and suspension viscosity of wood cellulose nanofibers. Polym J 46(1):73–76

Jiang Y, Liu X, Yang Q, Song X, Qin C, Wang S, Li K (2018) Effects of residual lignin on mechanical defibrillation process of cellulosic fiber for producing lignocellulose nanofibrils. Cellulose 25(11):6479–6494

Jiang Y, Liu X, Yang Q, Song X, Qin C, Wang S, Li K (2019) Effects of residual lignin on composition, structure and properties of mechanically defibrillated cellulose fibrils and films. Cellulose 26(3):1577–1593

Jin Z, Katsumata KS, Lam TBT, Iiyama K (2006) Covalent linkages between cellulose and lignin in cell walls of coniferous and nonconiferous woods. Biopolym Orig Res Biomol 83(2):103–110

Johansson A, Aaltonen O, Ylinen P (1987) Organosolv pulping methods and pulp properties. Biomass 13(1):45–65

Jonoobi M, Oladi R, Davoudpour Y, Oksman K, Dufresne A, Hamzeh Y, Davoodi R (2015) Different preparation methods and properties of nanostructured cellulose from various natural resources and residues: a review. Cellulose 22(2):935–969

Karim Z, Afrin S, Husain Q, Danish R (2017) Necessity of enzymatic hydrolysis for production and functionalization of nanocelluloses. Crit Rev Biotechnol 37(3):355–370

Kishani S, Vilaplana F, Xu W, Xu C, Wágberg L (2018) Solubility of softwood hemicelluloses. Biomacromol 19(4):1245–1255

Krishnan JM (2010) Rheology of complex fluids. In: Deshpande AP, Kumar PS (eds). Springer, Berlin

Kumagai A, Endo T (2018) Comparison of the surface constitutions of hemicelluloses on lignocellulosic nanofibers prepared from softwood and hardwood. Cellulose 25(7):3885–3897

Kumagai A, Lee SH, Endo T (2013) Thin film of lignocellulosic nanofibrils with different chemical composition for QCM-D study. Biomacromolecules 14(7):2420–2426

Kumagai A, Iwamoto S, Lee SH, Endo T (2014) Quartz crystal microbalance with dissipation monitoring of the enzymatic hydrolysis of steam-treated lignocellulosic nanofibrils. Cellulose 21(4):2433–2444

Kumagai A, Lee SH, Endo T (2016) Evaluation of the effect of hot-compressed water treatment on enzymatic hydrolysis of lignocellulosic nanofibrils with different lignin content using a quartz crystal microbalance. Biotechnol Bioeng 113(7):1441–1447

Lan TQ, Lou H, Zhu JY (2013) Enzymatic saccharification of lignocelluloses should be conducted at elevated pH 5.2–6.2. BioEnergy Res 6(2):476–485

Lasseuguette E, Roux D, Nishiyama Y (2008) Rheological properties of microfibrillar suspension of TEMPO-oxidized pulp. Cellulose 15(3):425–433

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose–Its barrier properties and applications in cellulosic materials: A review. Carbohydr Polym 90(2):735–764

Lê HQ, Dimic-Misic K, Johansson LS, Maloney T, Sixta H (2018) Effect of lignin on the morphology and rheological properties of nanofibrillated cellulose produced from γ-valerolactone/water fractionation process. Cellulose 25(1):179–194

Lindeboom J, Mulder BM, Vos JW, Ketelaar T, Emons AMC (2008) Cellulose microfibril deposition: coordinated activity at the plant plasma membrane. J Microsc 231(2):192–200

Liu H, Sun J, Leu SY, Chen S (2016) Toward a fundamental understanding of cellulase-lignin interactions in the whole slurry enzymatic saccharification process. Biofuels Bioprod Biorefin 10(5):648–663

Ma Q, Zhu J, Gleisner R, Yang R, Zhu JY (2018) Valorization of wheat straw using a recyclable hydrotrope at low temperatures (≤ 90° C). ACS Sustain Chem Eng 6(11):14480–14489

Mahendra IP, Wirjosentono B, Ismail H, Mendez JA (2019) Thermal and morphology properties of cellulose nanofiber from TEMPO-oxidized lower part of empty fruit bunches (LEFB). Open Chem 17(1):526–536

Martín-Sampedro R, Rahikainen JL, Johansson LS, Marjamaa K, Laine J, Kruus K, Rojas OJ (2013) Preferential adsorption and activity of monocomponent cellulases on lignocellulose thin films with varying lignin content. Biomacromolecules 14(4):1231–1239

Meier H (1962) Chemical and morphological aspects of the fine structure of wood. Pure Appl Chem 5(1–2):37–52

Moniruzzaman M, Goto M (2019) Ionic liquid pretreatment of lignocellulosic biomass for enhanced enzymatic delignification. Appl Ion Liq Biotechnol 61–77

Naderi A, Lindström T (2015) Rheological measurements on nanofibrillated cellulose systems: a science in progress. In: Cellulose and cellulose derivatives: synthesis, modification and applications. Nova Science Publishers, New York, pp 187–204

Nair SS, Yan N (2015) Effect of high residual lignin on the thermal stability of nanofibrils and its enhanced mechanical performance in aqueous environments. Cellulose 22(5):3137–3150

Nair SS, Zhu JY, Deng Y, Ragauskas AJ (2014) Characterization of cellulose nanofibrillation by micro grinding. J Nanopart Res 16(4):2349

Nechyporchuk O, Belgacem MN, Pignon F (2014) Rheological properties of micro-/nanofibrillated cellulose suspensions: wall-slip and shear banding phenomena. Carbohydr polymers 112:432–439

Nechyporchuk O, Belgacem MN, Bras J (2016) Production of cellulose nanofibrils: a review of recent advances. Ind Crops Prod 93:2–25

Nechyporchuk O, Belgacem MN, Pignon F (2016) Current progress in rheology of cellulose nanofibril suspensions. Biomacromolecules 17(7):2311–2320

Nie S, Zhang K, Lin X, Zhang C, Yan D, Liang H, Wang S (2018) Enzymatic pretreatment for the improvement of dispersion and film properties of cellulose nanofibrils. Carbohydr Polym 181:1136–1142

Ochoa-Villarreal M, Aispuro-Hernández E, Vargas-Arispuro I, Martínez-Téllez MÁ (2012) Plant cell wall polymers: function, structure and biological activity of their derivatives. In: Polymerization. InTech

Okita Y, Saito T, Isogai A (2009) TEMPO-mediated oxidation of softwood thermomechanical pulp. Holzforschung 63(5):529–535

Oksanen T, Buchert J, Viikari L (1997) The role of hemicelluloses in the hornification of bleached kraft pulps. Holzforschung-Int J Biol Chem Phys Technol Wood 51(4):355–360

Osong SH, Norgren S, Engstrand P, Lundberg M, Reza M, Tapani V (2016) Qualitative evaluation of microfibrillated cellulose using the crill method and some aspects of microscopy. Cellulose 23(6):3611–3624

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8(6):1934–1941

Pandey KK (1999) A study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy. J Appl Polym Sci 71(12):1969–1975

Park CW, Han SY, Namgung HW, Seo PN, Lee SY, Lee SH (2017) Preparation and characterization of cellulose nanofibrils with varying chemical compositions. BioResources 12(3):5031–5044

Pauly M, Keegstra K (2008) Cell-wall carbohydrates and their modification as a resource for biofuels. Plant J 54(4):559–568

Pérez J, Munoz-Dorado J, de la Rubia TDLR, Martinez J (2002) Biodegradation and biological treatments of cellulose, hemicellulose and lignin: an overview. Int Microbiol 5(2):53–63

Peterlin A, Ingram P (1970) Morphology of secondary wall fibrils in cotton. Text Res J 40(4):345–354

Pinto PC, Evtuguin DVy, Neto CP (2005) Efecto de las características estructurales de los biopolímeros de madera en el rendimiento de la fabricación de pasta y blanqueo de madera dura. Invest Quím Ind Ing 44(26):9777–9784

Plackett D, Anturi H, Hedenqvist M, Ankerfors M, Gällstedt M, Lindström T, Siró I (2010) Physical properties and morphology of films prepared from microfibrillated cellulose and microfibrillated cellulose in combination with amylopectin. J Appl Polym Sci 117(6):3601–3609

Postek MT, Moon RJ, Rudie AW, Bilodeau MA (2013) Production and applications of cellulose. Tappi Press, Peachtree Corners

Qin Y, Qiu X, Zhu JY (2016) Understanding longitudinal wood fiber ultra-structure for producing cellulose nanofibrils using disk milling with diluted acid prehydrolysis. Sci Rep 6:35602

Qing Y, Sabo R, Zhu JY, Agarwal U, Cai Z, Wu Y (2013) A comparative study of cellulose nanofibrils disintegrated via multiple processing approaches. Carbohydr Polym 97(1):226–234

Rezaei A, Nasirpour A, Fathi M (2015) Application of cellulosic nanofibers in food science using electrospinning and its potential risk. Compr Rev Food Sci Food Saf 14(3):269–284

Rojo E, Peresin MS, Sampson WW, Hoeger IC, Vartiainen J, Laine J, Rojas OJ (2015) Comprehensive elucidation of the effect of residual lignin on the physical, barrier, mechanical and surface properties of nanocellulose films. Green Chem 17(3):1853–1866

Saarinen T, Lille M, Seppälä J (2009) Technical aspects on rheological characterization of microfibrillar cellulose water suspensions. Annu Trans Nord Rheol Soc 17:121–128

Saito T, Nishiyama Y, Putaux JL, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7(6):1687–1691

Santucci BS, Bras J, Belgacem MN, da Silva Curvelo AA, Pimenta MTB (2016) Evaluación de los efectos de la composición química y los tratamientos de refinación sobre las propiedades de las películas de celulosa nanofibriladas del bagazo de caña de azúcar. Cultivos y productos industriales 91:238–248

Sarkar P, Bosneaga E, Auer M (2009) Plant cell walls throughout evolution: towards a molecular understanding of their design principles. J Exp Bot 60(13):3615–3635

Seo PN, Han SY, Park CW, Lee SY, Kim NH, Lee SH (2019) Effect of alkaline peroxide treatment on the chemical compositions and characteristics of lignocellulosic nanofibrils. BioResources 14(1):193–206

Shao Z, Li K (2006) The effect of fiber surface lignin on interfiber bonding. J Wood Chem Technol 26(3):231–244

Širc J, Hobzová R, Kostina N, Munzarová M, Juklícková M, Lhotka M, Michálek J (2012) Morphological characterization of nanofibers: methods and application in practice. J Nanomater 2012:121

Sjöström E (1993) Wood chemistry: fundamentals and applications, 2nd edn. Academic Press, San Diego

Solala I, Volperts A, Andersone A, Dizhbite T, Mironova-Ulmane N, Vehniäinen A, Pere J, Vuorinen T (2012) Mechanoradical formation and its effects on birch kraft pulp during the preparation of nanofibrillated cellulose with Masuko refining. Holzforschung 66(4):477–483

Spence KL, Venditti RA, Habibi Y, Rojas OJ, Pawlak JJ (2010) The effect of chemical composition on microfibrillar cellulose films from wood pulps: mechanical processing and physical properties. Bioresour Technol 101(15):5961–5968

Spence KL, Venditti RA, Rojas OJ, Habibi Y, Pawlak JJ (2011) A comparative study of energy consumption and physical properties of microfibrillated cellulose produced by different processing methods. Cellulose 18(4):1097–1111

Stelte W, Sanadi AR (2009) Preparation and characterization of cellulose nanofibers from two commercial hardwood and softwood pulps. Ind Eng Chem Res 48(24):11211–11219

Sun XF, Sun RC, Su Y, Sun JX (2004) Comparative study of crude and purified cellulose from wheat straw. J Agric Food Chem 52(4):839–847

Sun X, Wu Q, Lee S, Qing Y, Wu Y (2016) Cellulose nanofibers as a modifier for rheology, curing and mechanical performance of oil well cement. Sci Rep 6:31654

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16(1):75

Tagami A, Gioia C, Lauberts M, Budnyak T, Moriana R, Lindström ME, Sevastyanova O (2019) Solvent fractionation of softwood and hardwood kraft lignins for more efficient uses: compositional, structural, thermal, antioxidant and adsorption properties. Ind Crops Prod 129:123–134

Taheri H, Samyn P (2016) Effect of homogenization (microfluidization) process parameters in mechanical production of micro-and nanofibrillated cellulose on its rheological and morphological properties. Cellulose 23(2):1221–1238

Tanaka R, Saito T, Hondo H, Isogai A (2015) Influence of flexibility and dimensions of nanocelluloses on the flow properties of their aqueous dispersions. Biomacromolecules 16(7):2127–2131

Tarrés Q, Ehman NV, Vallejos ME, Area MC, Delgado-Aguilar M, Mutjé P (2017) Lignocellulosic nanofibers from triticale straw: the influence of hemicelluloses and lignin in their production and properties. Carbohydr Polym 163:20–27

Thakur VK, Thakur MK, Raghavan P, Kessler MR (2014) Progress in green polymer composites from lignin for multifunctional applications: a review. ACS Sustain Chem Eng 2(5):1072–1092

Turbak AF, Snyder FW, Sandberg KR (1983) U.S. Patent No. 4,374,702. U.S. Patent and Trademark Office, Washington

Vänskä E, Vihelä T, Peresin MS, Vartiainen J, Hummel M, Vuorinen T (2016) Residual lignin inhibits thermal degradation of cellulosic fiber sheets. Cellulose 23(1):199–212

Varanasi S, He R, Batchelor W (2013) Estimation of cellulose nanofibre aspect ratio from measurements of fibre suspension gel point. Cellulose 20(4):1885–1896

Wang QQ, Zhu JY, Gleisner R, Kuster TA, Baxa U, McNeil SE (2012a) Morphological development of cellulose fibrils of a bleached eucalyptus pulp by mechanical fibrillation. Cellulose 19(5):1631–1643

Wang ZJ, Zhu JY, Zalesny Jr RS, Chen KF (2012b) Ethanol production from poplar wood through enzymatic saccharification and fermentation by dilute acid and SPORL pretreatments. Fuel 95:606–614

Wang H, Zhang X, Jiang Z, Li W, Yu Y (2015) A comparison study on the preparation of nanocellulose fibrils from fibers and parenchymal cells in bamboo (Phyllostachys pubescens). Ind Crops Prod 71:80–88

Wen Y, Yuan Z, Liu X, Qu J, Yang S, Wang A, Wei B, Xu J, Ni Y (2019) Preparation and characterization of lignin-containing cellulose nanofibril from poplar high-yield pulp via TEMPO-mediated oxidation and homogenization. ACS Sustain Chem Eng 7(6):6131–6139

Xu J, Fu Y, Tian G, Li Q, Liu N, Qin M, Wang Z (2018) Mild and efficient extraction of hardwood hemicellulose using recyclable formic acid/water binary solvent. Bioresour Technol 254:353–356

Zhang J, Choi YS, Yoo CG, Kim TH, Brown RC, Shanks BH (2015) Cellulose–hemicellulose and cellulose–lignin interactions during fast pyrolysis. ACS Sustain Chem Eng 3(2):293–301

Zimmermann T, Pöhler E, Geiger T (2004) Cellulose fibrils for polymer reinforcement. Adv Eng Mater 6(9):754–761

Acknowledgments

This work was funded by the Agencia Nacional de Investigación y Desarrollo (ANID)/Doctorado Nacional/2018-21181080 and Agencia Nacional de Investigación y Desarrollo (ANID)/Doctorado Nacional/2019-21190348. Conicyt PIA/Apoyo CCTE AFB 170007.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Albornoz-Palma, G., Ching, D., Valerio, O. et al. Effect of lignin and hemicellulose on the properties of lignocellulose nanofibril suspensions. Cellulose 27, 10631–10647 (2020). https://doi.org/10.1007/s10570-020-03304-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03304-5