Abstract

A simple and green method for the preparation of nanofibrillated cellulose (NFC) by heating surgical cotton in glycerol is demonstrated as an alternative to the existing mechanical degradation method. The heat treatment of cotton in the presence of 9% w/w sulphuric acid in glycerol (1 M), under relatively milder conditions than those reported in the literature in the absence of glycerol, resulted in the formation of nanocrystalline cellulose (NCC) due to extensive hydrolysis of the amorphous segments. The method reported offers certain unique advantages in the preparation of NFC such as high yield (71%) and much easier post-processing compared to the mechanical degradation method of preparation of NFC. It also offers certain unique advantages in the preparation of NCC such as relatively high yield (56%), the use of lesser quantity of sulphuric acid as well as elimination of the quenching of the reaction through the addition of excess water to the reaction mixture. The residual ‘green solvent’, separated by decantation or centrifugal separation, post-reaction, could be reused for several cycles after filtration with activated carbon. A simple utility of the NCC prepared as reinforcing additive to cement is demonstrated. The addition of 1% (w/w of cement) of NCC and tetraethylorthosilicate modified NCC enhanced the workability of cement mortar and the compressive strength of cured cement composite in sharp contrast to the use of microcrystalline cellulose that required 10% (w/w) for the same enhancement in strength but with poorer workability.

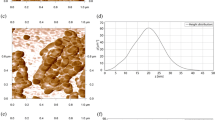

Graphical abstract

A sustainable route for preparing NFC through heat treatment in glycerol is reported. In the presence of 1 M (9% w/w) sulphuric acid in glycerol, similar heat treatment resulted in the formation of both NFC and NCC. The residual ‘green solvent’ could be reused for several cycles. The addition of 1% (w/w) of nanocellulose prepared via this method enhanced the workability of cement mortar and the compressive strength of cured cement composite.

Similar content being viewed by others

References

Abdelmouleh M, Boufi S, Ben Salah A, Belgacem MN, Gandini A (2002) Interaction of silane coupling agents with cellulose. Langmuir 18:3203–3208. https://doi.org/10.1021/la011657g

Anju TR, Ramamurthy K, Dhamodharan R (2016) Surface modified microcrystalline cellulose from cotton as a potential mineral admixture in cement mortar composite. Cem Concr Compos 74:147–153. https://doi.org/10.1016/j.cemconcomp.2016.09.003

ASTM C109 (2013) Test method for compressive strength of hydraulic cement mortar. American Society for Testing and Materials, West Conshohocken

ASTM C1437 (2013) Test method for flow of hydraulic cement mortar. American Society for Testing and Materials, West Conshohocken

Basch A, Lewin M (1973) The influence of fine structure on the pyrolysis of cellulose. I. Vacuum pyrolysis. J Polym Sci Part A Polym Chem 11:3071–3093. https://doi.org/10.1002/pol.1973.170111204

Chakraborty A (2004) Ph.D. thesis, University of Toronto

Collard FX, Blin J (2014) A review on pyrolysis of biomass constituents: mechanisms and composition of the products obtained from the conversion of cellulose, hemicelluloses and lignin. Renew Sustain Energy Rev 38:594–608. https://doi.org/10.1016/j.rser.2014.06.013

Dai D, Fan M, Collins P (2013) Fabrication of nanocelluloses from hemp fibers and their application for the reinforcement of hemp fibers. Ind Crops Prod 44:192–199. https://doi.org/10.1016/j.indcrop.2012.11.010

Dinand E, Chanzy H, Vignon RM (1999) Suspensions of cellulose microfibrils from sugar beet pulp. Food Hydrocoll 13:275–283. https://doi.org/10.1016/S0268-005X(98)00084-8

Dufresne A, Cavaille JY, Vignon MR (1997) Mechanical behavior of sheets prepared from sugar beet cellulose microfibrils. J Appl Polym Sci 64:1185–1194. https://doi.org/10.1002/(SICI)1097-4628(19970509)64:6%3c1185:AID-APP19%3e3.0.CO;2-V

Duran N, Lemes AP, Seabra AB (2012) Review of cellulose nanocrystals patents: preparation, composites and general applications. Recent Pat Nanotechnol 6:16–28. https://doi.org/10.2174/187221012798109255

Epure V, Griffon M, Pollet E, Avérous L (2011) Structure and properties of glycerol-plasticized chitosan obtained by mechanical kneading. Carbohydr Polym 83:947–952. https://doi.org/10.1016/j.carbpol.2010.09.003

Espinosa SC, Kuhnt T, Foster EJ, Weder C (2013) Isolation of thermally stable cellulose nanocrystals by phosphoric acid hydrolysis. Biomacromolecules 14:1223–1230. https://doi.org/10.1021/bm400219u

Islam MT, Alam MM, Patrucco A, Montarsolo A, Zoccola M (2014) Preparation of nanocellulose: a review. AATCC J Res 1:17–23. https://doi.org/10.14504/ajr.1.5.3

Jia X, Chen Y, Shi C, Ye Y, Wang P, Zeng X, Wu T (2013) Preparation and characterization of cellulose regenerated from phosphoric acid. J Agric Food Chem 61:12405–12414. https://doi.org/10.1021/jf4042358

Kamel S (2007) Nanotechnology and its applications in lignocellulosic composites, a mini review. Express Polym Lett 1:546–575. https://doi.org/10.3144/expresspolymlett.2007.78

Kargarzadeh H, Ioelovich M, Ahmad I, Thomas S, Dufresne A (2017) Handbook of nanocellulose and cellulose nanocomposites. Wiley-VCH Verlag GmbH & Co. KgaA, New York. https://doi.org/10.1002/9783527689972

Kaushik M, Moores A (2016) Review: nanocelluloses as versatile supports for metal nanoparticles and their applications in catalysis. Green Chem 18:622–637. https://doi.org/10.1039/C5GC02500A

Klemm D, Kramer F, Moritz S, Lindstrom T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of natural-based materials. Angew Chem Int Ed 50:5438–5466. https://doi.org/10.1002/anie.201001273

Kos T, Anžlovar A, Kunaver M, Huskić M, Žagar E (2014) Fast preparation of nanocrystalline cellulose by microwave-assisted hydrolysis. Cellulose 21:2579–2585. https://doi.org/10.1007/s10570-014-0315-2

Kunaver M, Anzlovar A, Zagar E (2016) The fast and effective isolation of nanocellulose from selected cellulosic feedstocks. Carbohydr Polym 148:251–258. https://doi.org/10.1016/j.carbpol.2016.04.076

Li W, Wang R, Liu S (2011) Nanocrystalline cellulose prepared from softwood kraft pulp via ultrasonic-assisted acid hydrolysis. BioResources 6:4271–4281. https://doi.org/10.15376/biores.6.4.4271-4281

Lu Q, Yang XC, Dong CQ, Zhang ZF, Zhang XM, Zhu XF (2011) Influence of pyrolysis temperature and time on the cellulose fast pyrolysis products: analytical Py-GC/MS study. J Anal Appl Pyrol 92:430–438. https://doi.org/10.1016/j.jaap.2011.08.006

Lu QL, Li XY, Tang LR, Lu BL, Huang B (2015) One-pot tandem reactions for the preparation of esterified cellulose nanocrystals with 4-dimethylaminopyridine as a catalyst. RSC Adv 5:56198–56204. https://doi.org/10.1039/C5RA08690F

Maiti S, Jayaramudu J, Das K, Reddy SM, Sadiku R, Ray SS, Liu D (2013) Preparation and characterization of nano-cellulose with new shape from different precursor. Carbohydr Polym 98:562–567. https://doi.org/10.1016/j.carbpol.2013.06.029

McCann MC, Wells B, Roberts K (1990) Direct visualization of cross-links in the primary plant cell wall. J Cell Sci 96:323–334

Navell TP, Zeronian SH (1985) Intercrystalline swelling of cellulose. In: Zeronian SH, Nevell TP (eds) Cellulose chemistry and its applications. Wiley, New York. https://doi.org/10.1002/pol.1987.140250212

Pääkko M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941. https://doi.org/10.1021/bm061215p

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:10

Pastorova I, Arisz PW, Boon JJ (1993) Preservation of d-glucose-oligosaccharides in cellulose chars. Carbohydr Res 248:151–165. https://doi.org/10.1016/0008-6215(93)84123-N

Patwardhan PR, Satrio JA, Brown RC, Shanks BH (2009) Product distribution from fast pyrolysis of glucose-based carbohydrates. J Anal Appl Pyrol 86:323–330. https://doi.org/10.1016/j.jaap.2009.08.007

Rajinipriya M, Nagalakshmaiah M, Robert M, Elkoun S (2018) Importance of agricultural and industrial waste in the field of nanocellulose and recent industrial developments of wood based nanocellulose: a review. ACS Sustain Chem Eng 6:2807–2828. https://doi.org/10.1021/acssuschemeng.7b03437

Sadeghifar H, Filpponen E, Clarke SP, Brougham DF, Argyropoulos DS (2011) Production of cellulose nanocrystals using hydrobromic acid and click reactions on their surface. J Mater Sci 46:7344–7355. https://doi.org/10.1007/s10853-011-5696-0

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491. https://doi.org/10.1021/bm0703970

Sannino A, Demitri C, Madahiele M (2009) Biodegradable cellulose-based hydrogels: design and applications. Materials 2:353–373. https://doi.org/10.3390/ma2020353

Scheirs J, Camino G, Tumiatti W (2001) Overview of water evolution during the thermal degradation of cellulose. Eur Polym J 37:933–942. https://doi.org/10.1016/S0014-3057(00)00211-1

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Serizawa T, Sawada T, Okura H, Wada M (2013) Hydrolytic activities of crystalline cellulose nanofibers. Biomacromolecules 14:613–617. https://doi.org/10.1021/bm4000822

Shafizadeh F (1968) Pyrolysis and combustion of cellulosic materials. Adv Carbohydr Chem 23:419–474. https://doi.org/10.1016/S0096-5332(08)60173-3

Shafizadeh F (1982) Introduction to pyrolysis of biomass. J Anal Appl Pyrol 3:283–305. https://doi.org/10.1016/0165-2370(82)80017-X

Soltes EJ, Wiley AT, Lin SCK (1981) Biomass pyrolysis-towards an understanding of its versatility and potentials. Biotechnol Bioeng Symp Ser 11:125–136

Stöber W, Fink A, Bohn E (1968) Controlled growth of monodisperse silica spheres in the micron size range. J Colloid Interface Sci 26:62–69. https://doi.org/10.1016/0021-9797(68)90272-5

Tang MM, Bacon R (1964) Carbonization of cellulose fibers—I. Low temperature pyrolysis. Carbon 2:211–220. https://doi.org/10.1016/0008-6223(64)90035-1

Vom Stein T, Grande P, Sibilla F, Commandeur U, Fischer R, Leitner W, Domínguez de María P (2010) Salt-assisted organic-acid-catalysed depolymerization of cellulose. Green Chem 12:1844–1849. https://doi.org/10.1039/C0GC00262C

Xiao YT, Chin WL, Abd Hamid SB (2015) Facile preparation of highly crystalline nanocellulose by using ionic liquid. Adv Mater Res 1087:106–110. https://doi.org/10.4028/www.scientific.net/AMR.1087.106

Yu H, Qin Z, Liang B, Liu N, Zhou Z, Chen L (2013) Facile extraction of thermally stable cellulose nanocrystals with a high yield of 93% through hydrochloric acid hydrolysis under hydrothermal conditions. J Mater Chem A 1:3938–3944. https://doi.org/10.1039/C3TA01150J

Zhou X, Nolte MW, Mayes HB, Shanks BH, Broadbelt LJ (2014) Experimental and mechanistic modeling of fast pyrolysis of neat glucose-based carbohydrates. 1. Experiments and development of a detailed mechanistic model. Ind Eng Chem Res 53:13274–13289. https://doi.org/10.1021/ie502259w

Zimmermann T, Bordeanu N, Strub E (2010) Properties of nanofibrillated cellulose from different raw materials and its reinforcement potential. Carbohydr Polym 79:1086–1093

Acknowledgments

The authors thank the Department of Materials and Metallurgical Engineering, IIT Madras for extending the TEM facility and Prof.S. Ramaprabhu, Department of Physics, IIT Madras for enabling zeta potential measurements and dynamic light scattering experiments. The authors thank Prof. K. Ramamurthy of the Department of Civil Engineering, IIT Madras for guiding the work on cement-reinforcement studies and testing. The work presented here is a part of Indian patent application (201841019186) filed by the authors. This work was supported by IIT Madras.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Raghavachari Dhamodharan: This work constitutes a part of Indian Patent Application No. 201841019186.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ramakrishnan, A., Ravishankar, K. & Dhamodharan, R. Preparation of nanofibrillated cellulose and nanocrystalline cellulose from surgical cotton and cellulose pulp in hot-glycerol medium. Cellulose 26, 3127–3141 (2019). https://doi.org/10.1007/s10570-019-02312-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02312-4