Abstract

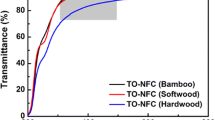

In this work, quaternized nanofibrillated cellulose (Q-NFC) was isolated from bamboo bleached kraft pulp through the pre-treatment using 2, 3-epoxy-propyltrimethylammonium chloride (EPTAC) in an aqueous alkaline media and subsequent high-pressure homogenization. A series of aqueous Q-NFC dispersions with different contents of positively charged trimethylammonium groups on the surfaces of fibrils were obtained. With the amount of added EPTAC increased, the solid recovery ratio, surface charge contents, zeta potential values, and extent of nanofibrillation gradually increased for the as-obtained Q-NFCs. TEM images of Q-NFCs revealed that the incorporation of quaternary ammonium groups contributed to the defibrillation into finer nanofibrils with more uniform width distribution. With an increase in the positive charge contents, both degree of polymerization and decomposition temperature of the Q-NFC films decreased slowly. Steady-state rheological result demonstrated that the maximum shear viscosity was achieved for the Q-NFC0.6 dispersion with the medium charge content. The Q-NFC films with higher charge content displayed superior transparency and tensile strength. Furthermore, the oxygen transmission rate of PLA films was remarkably decreased dramatically from 216.0 to 10.3 mL m−2 day−1 after laminating a thin layer of Q-NFC0.6 on the one side. As compared to TEMPO-oxidized NFC from the same pulp, the surface-charged Q-NFC exhibited higher optical transmittance, shear viscosity, and thermal stability as well as comparable oxygen-barrier properties.

Graphical abstract

Similar content being viewed by others

References

Abbott AP, Bell TJ, Handa S, Stoddart B (2006) Cationic functionalisation of cellulose using a choline based ionic liquid analogue. Green Chem 8:784–786

Abdul Khalil HP, Davoudpour Y, Islam MN, Mustapha A, Sudesh K, Dungani R, Jawaid M (2014) Production and modification of nanofibrillated cellulose using various mechanical processes: a review. Carbohydr Polym 99:649–665

Andresen M, Stenstad P, Møretrø T, Langsrud S, Syverud K, Johansson LS, Stenius P (2007) Nonleaching antimicrobial films prepared from surface-modified microfibrillated cellulose. Biomacromolecules 8:2149–2155

Aulin C, Johansson E, Wågberg L, Lindström T (2010a) Self-organized films from cellulose I nanofibrils using the Layer-by-Layer technique. Biomacromolecules 11:872–882

Aulin C, Gällstedt M, Lindström T (2010b) Oxygen and oil barrier properties of microfibrillated cellulose films and coatings. Cellulose 17:559–574

Azeredo HMC, Rosa MF, Mattoso LHC (2017) Nanocellulose in bio-based food packaging applications. Ind Crops Prod 97:664–671

Belbekhouche S, Bras J, Siqueira G, Chappey C, Lebrun L, Khelifi B, Marais S, Dufresne A (2011) Water sorption behavior and gas barrier properties of cellulose whiskers and microfibrils films. Carbohydr Polym 83:1740–1748

Besbes I, Alila S, Boufi S (2011a) Nanofibrillated cellulose from TEMPO-oxidized eucalyptus fibres: effect of the carboxyl content. Carbohydr Polym 84:975–983

Besbes I, Vilar MR, Boufi S (2011b) Nanofibrillated cellulose from Alfa, Eucalyptus and Pine fibres: preparation, characteristics and reinforcing potential. Carbohydr Polym 86:1198–1206

Boufi S, González I, Delgado-Aguilar M, Tarrès Q, Pèlach MÀ, Mutjé P (2016) Nanofibrillated cellulose as an additive in papermaking process: a review. Carbohydr Polym 154:151–166

Carpenter AW, de Lannoy C, Wiesner MR (2015) Cellulose nanomaterials in water treatment technologies. Environ Sci Technol 49:5277–5287

Carr ME Jr, Shen LL, Hermans J (1977) Mass–length ratio of fibrin fibers from gel permeation and light scattering. Biopolymers 16:1–15

Chaker A, Boufi S (2015) Cationic nanofibrillar cellulose with high antibacterial properties. Carbohydr Polym 131:224–232

Chaker A, Alila S, Mutjé P, Vilar MR, Boufi S (2013) Key role of the hemicellulose content and the cell morphology on the nanofibrillation effectiveness of cellulose pulps. Cellulose 20:2863–2875

Chen Y, Geng B, Ru J, Tong C, Liu H, Chen J (2017a) Comparative characteristics of TEMPO-oxidized cellulose nanofibers and resulting nanopapers from bamboo, softwood, and hardwood pulps. Cellulose 24:4831–4844

Chen Y, Liu H, Geng B, Ru J, Cheng C, Zhao Y, Wang L (2017b) A reusable surface-quaternized nanocellulose-based hybrid cryogel loaded with N-doped TiO2 for self-integrated adsorption/photo-degradation of methyl orange dye. RSC Adv 7:17279–17288

Chen Y, Ru J, Geng B, Wng H, Tong C, Du C, Wu S, Liu H (2017c) Charge-functionalized and mechanically durable composite cryogels from Q-NFC and CS for highly selective removal of anionic dyes. Carbohydr Polym 174:841–848

Dufresne A (2012) Nanocellulose: from nature to high performance tailored materials. De Gruyter, Berlin, pp 373–409

Dufresne A (2013) Nanocellulose: a new ageless bionanomaterial. Mater Today 16:220–227

Fang Z, Zhu H, Yuan Y, Ha D, Zhu S, Preston C, Chen Q, Li Y, Han X, Lee S, Chen G, Li T, Munday J, Huang J, Hu L (2014) Novel nanostructured paper with ultrahigh transparency and ultrahigh haze for solar cells. Nano Lett 14:765–773

Feng J, Esker AR, Roman M (2010) Acid-catalyzed and solvolytic desulfation of H2SO4-hydrolyzed cellulose nanocrystals. Langmuir ACS J Surf Colloids 26:17919–17925

Fujisaki Y, Koga H, Nakajima Y, Nakata M, Tsuji H, Yamamoto T, Kurita T, Nogi M, Shimidzu N (2014) Transparent nanopaper-based flexible organic thin-film transistor array. Adv Funct Mater 24:1656

Fujisawa S, Okita Y, Fukuzumi H, Saito T, Isogai A (2011) Preparation and characterization of TEMPO-oxidized cellulose nanofibril films with free carboxyl groups. Carbohydr Polym 84:579–583

Fukuzumi H, Saito T, Iwata T, Kumamoto Y, Isogai A (2009) Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 10:162–165

Fukuzumi H, Saito T, Okita Y, Isogai A (2010) Thermal stabilization of TEMPO-oxidized cellulose. Polym Degrad Stab 95:1502–1508

Fukuzumi H, Saito T, Isogai A (2013) Influence of TEMPO-oxidized cellulose nanofibril length on film properties. Carbohydr Polym 93:172–177

Geng B, Wang H, Wu S, Ru J, Tong C, Chen Y, Liu H, Wu S, Liu X (2017) Surface-tailored nanocellulose aerogels with thiol-functional moieties for highly efficient and selective removal of Hg(II) ions from water. ACS Sustain Chem Eng 5:11715–11726

Gilbert RD, Kadla JF (2000) Cellulose modification. In: Meister JJ (ed) Polymer modification: principles, techniques and applications, 2nd edn. Marcel Dekker, New York, p 32

Hasani M, Cranston ED, Westman G, Gray DG (2008) Cationic surface functionalization of cellulose nanocrystals. Soft Matter 4:2238–2244

Henriksson M, Henriksson G, Berglund LA, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polym J 43:3434–3441

Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9:1579–1585

Ho TTT, Zimmermann T, Hauert R, Caseri W (2011) Preparation and characterization of cationic nanofibrillated cellulose from etherification and high-shear disintegration processes. Cellulose 18:1391–1406

Hu L, Zheng G, Yao J, Liu N, Weil B, Eskilsson M, Karabulut E, Ruan Z, Fan S, Bloking JT, McGehee MD, Wågberg L, Cui Y (2013) Transparent and conductive paper from nanocellulose fibers. Energy Environ Sci 6:513–518

Hubbe MA, Ferrer A, Tyagi P, Yin Y, Salas C, Pal L, Rojas OJ (2017) Nanocellulose in thin films, coatings, and plies for packaging applications: a review. Bioresources 12:2143–2233

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85

Iwamoto S, Nakagaito AH, Yano H (2007) Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appl Phys A 89:461–466

Jiang F, Hsieh Y-L (2014) Super water absorbing and shape memory nanocellulose aerogels from TEMPO-oxidized cellulose nanofibrils via cyclic freezing–thawing. J Mater Chem A 2:350–359

Klemm D, Philpp B, Heinze T, Heinze U, Wagenknecht W (2004a) Comprehensive cellulose chemistry, vol 2. Wiley, New York, p 257

Klemm D, Philpp B, Heinze T, Heinze U, Wagenknecht W (2004b) Comprehensive cellulose chemistry, vol 1. Wiley, New York, p 83

Klemm D, Philpp B, Heinze T, Heinze U, Wagenknecht W (2004c) Comprehensive cellulose chemistry, vol 1. Wiley, New York, p 106

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 42:5438–5466

Kumar V, Bollström R, Yang A, Chen Q, Chen G, Salminen P, Bousfield D, Toivakka M (2014) Comparison of nano- and microfibrillated cellulose films. Cellulose 21:3443–3456

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose—its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90:735–764

Li F, Mascheroni E, Piergiovanni L (2015) The potential of nanocellulose in the packaging field: a review. Packag Technol Sci 28:475–508

Liimatainen H, Suopajärvi T, Sirviö J, Hormi O, Niinimäki J (2014) Fabrication of cationic cellulosic nanofibrils through aqueous quaternization pretreatment and their use in colloid aggregation. Carbohydr Polym 103:187–192

Lindström T (2017) Aspects on nanofibrillated cellulose (NFC) processing, rheology and NFC-film properties. Curr Opin Colloid Interface Sci 29:68–75

Littunen K, Castro J, Samoylenko A, Xu Q, Quaggin S, Vainio S, Seppälä J (2016) Synthesis of cationized nanofibrillated cellulose and its antimicrobial properties. Eur Polym J 75:116–124

Liu H, Geng B, Chen Y, Wang H (2016a) Review on the aerogel-type oil sorbents derived from nanocellulose. ACS Sustain Chem Eng 5:49–66

Liu H, Chen Y, Geng B, Ru J, Du C, Jin C, Han J (2016b) Research progress in the cellulose based aerogel-type oil sorbents. Acta Polym Sin 5:545–559

Naderi A (2017) Nanofibrillated cellulose: properties reinvestigated. Cellulose 24:1933–1945

Naderi A, Lindström T, Erlandsson J, Sundström J, Flodberg G (2016a) A comparative study of the properties of three nano-fibrillated cellulose systems that have been produced at about the same energy consumption levels in the mechanical delamination step. Nord Pulp Pap Res J 31:364–371

Naderi A, Lindström T, Christoph FW, Flodberg G, Sundström J, Junel K, Erlandsson J, Runebjörk A (2016b) Phosphorylated nanofibrillated cellulose: production and properties. Nord Pulp Pap Res J 31:20–29

Nakagaito AN, Nogi M, Yano H (2010) Displays from transparent film of natural nanofibers. MRS Bull 35:214–218

Nechyporchuk O, Belgacem MN, Pignon F (2016a) Current progress in rheology of cellulose nanofibril suspensions. Biomacromolecules 17:2311–2320

Nechyporchuk O, Belgacem MN, Bras J (2016b) Production of cellulose nanofibrils: a review of recent advances. Ind Crops Prod 93:2–25

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Iβ from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124:9074–9082

Nogi M (2009) Optically transparent nanofiber paper. Adv Mater 21:1595–1598

Nogi M, Yano H (2009) Optically transparent nanofiber sheets by deposition of transparent materials: a concept for a roll-to-roll processing. Appl Phys Lett 94:233117

Nogi M, Kim C, Sugahara T, Inui T, Takahashi T, Suganuma K (2013) High thermal stability of optical transparency in cellulose nanofiber paper. Appl Phys Lett 102:181911

Okahisa Y, Yoshida A, Miyaguchi S, Yano H (2009) Optically transparent wood–cellulose nanocomposite as a base substrate for flexible organic light-emitting diode displays. Compos Sci Technol 69:1958–1961

Oleksandr N, Mohamed NB, Julien B (2015) Production of cellulose nanofibrils: a review of recent advances. Ind Crops Prod 93:2–25

Olszewska A, Eronen P, Johansson L-S, Malho J-M, Ankerfors M, Lindström T, Ruokolainen J, Laine J, Österberg M (2011) The behaviour of cationic nanofibrillar cellulose in aqueous media. Cellulose 18:1213

Osong SH, Norgren S, Engstrand P (2016) Processing of wood-based microfibrillated cellulose and nanofibrillated cellulose, and applications relating to papermaking: a review. Cellulose 23:1–31

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Osterberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941

Pei A, Butchosa N, Berglund LA, Zhou Q (2013) Surface quaternized cellulose nanofibrils with high water absorbency and adsorption capacity for anionic dyes. Soft Matter 9:2047–2055

Puangsin B, Yang Q, Saito T, Isogai A (2013) Comparative characterization of TEMPO-oxidized cellulose nanofibril films prepared from non-wood resources. Int J Biol Macromol 59:208–213

Rodionova G, Lenes M, Eriksen Ø, Gregersen Ø (2011) Surface chemical modification of microfibrillated cellulose: improvement of barrier properties for packaging applications. Cellulose 18:127–134

Rodionova G, Saito T, Lenes M, Eriksen Ø, Gregersen Ø, Fukuzumi H, Isogai A (2012) Mechanical and oxygen barrier properties of films prepared from fibrillated dispersions of TEMPO-oxidized Norway spruce and Eucalyptus pulps. Cellulose 19:705–711

Ru J, Geng B, Tong C, Wang H, Wu S, Liu H (2017) Nanocellulose-based adsorption materials. Prog Chem 10:1228–1251

Saini S, Yücel FÇ, Belgacem MN, Bras J (2016) Surface cationized cellulose nanofibrils for the production of contact active antimicrobial surfaces. Carbohydr Polym 135:239–247

Saito T, Nishiyama Y, Putaux JL, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7:1687–1691

Saito Tsuguyuki, Kimura Satoshi, Yoshiharu Nishiyama A, Isogai Akira (2007) Cellulose nanofibers prepared by TEMPO-Mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491

Saito T, Hirota M, Tamura N, Kimura S, Fukuzumi H, Heux L, Isogai A (2009) Individualization of nano-sized plant cellulose fibrils by direct surface carboxylation using TEMPO catalyst under neutral conditions. Biomacromolecules 10:1992–1996

Scherrer P (1918) Estimation of the size and internal structure of colloidal particles by means of rontgen. NachrGeswiss Gottingen 2:98–112

Segal LC, Creely J, Martin AEJ, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-Ray diffractometer. Text Res J 29:786–794

Shinoda R, Saito T, Okita Y, Isogai A (2012) Relationship between length and degree of polymerization of TEMPO-oxidized cellulose nanofibrils. Biomacromolecules 13:842–849

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Siró I, Plackett D, Hedenqvist MS, Ankerfors M, Lindström T (2011) Highly transparent films from carboxymethylated microfibrillated cellulose: the effect of multiple homogenization steps on key properties. J Appl Polym Sci 119:2652–2660

Smith DK, Bampton RF, Alexander WJ (1963) Use of new solvents for evaluating chemical cellulose for the viscose process. Ind Eng Chem Process Des Dev 2:57–62

Stelte W, Sanadi A (2009) Preparation and characterization of cellulose nanofibers from two commercial hardwood and softwood pulps. Ind Eng Chem Res 48:11211–11219

Takaichi S, Saito T, Tanaka R, Isogai A (2014) Improvement of nanodispersibility of oven-dried TEMPO-oxidized celluloses in water. Cellulose 21:4093–4103

Voisin H, Bergström L, Liu P, Mathew AP (2017) Nanocellulose-based materials for water purification. Nanomaterials 7:57

Wei J, Chen Y, Liu H, Du C, Yu H, Ru J, Zhou Z (2016a) Effect of surface charge content in the TEMPO-oxidized cellulose nanofibers on morphologies and properties of poly (N -isopropylacrylamide)-based composite hydrogels. Ind Crops Prod 92:227–235

Wei J, Chen Y, Liu H, Du C, Yu H, Zhou Z (2016b) Thermo-responsive and compression properties of TEMPO-oxidized cellulose nanofiber-modified PNIPAm hydrogels. Carbohydr Polym 147:201–207

Wu W, Tassi NG, Zhu H, Fang Z, Hu L (2015) Nanocellulose-based translucent diffuser for optoelectronic device applications with dramatic improvement of light coupling. ACS Appl Mater Interfaces 7:26860–26864

Wu B, Geng B, Chen Y, Liu H, Li G, Wu Q (2017) Preparation and characteristics of TEMPO-oxidized cellulose nanofibrils from bamboo pulp and their oxygen-barrier application in PLA films. Front Chem Sci Eng 11:554–563

Yagyu H, Saito T, Isogai A, Koga H, Nogi M (2015) Chemical modification of cellulose nanofibers for the production of highly thermal resistant and optically transparent nanopaper for paper devices. ACS Appl Mater Interfaces 7:22012–22017

Yao Y, Tao J, Zou J, Zhang B, Li T, Dai J, Zhu M, Wang S, Fu K, Henderson D, Hitz E, Peng J, Hu L (2016) Light management in plastic-paper hybrid substrate towards high-performance optoelectronics. Energy Environ Sci 9:2278–2285

Zhu H, Zhu S, Jia Z, Parvinian S, Li Y, Vaaland O, Hu L, Li T (2015) Anomalous scaling law of strength and toughness of cellulose nanopaper. Proc Natl Acad Sci 112:8971–8976

Acknowledgments

The authors are grateful for the financial supports from the Public Welfare Projects of Zhejiang Province (No. 2017C33113), Opening Project from CAS Key Laboratory of Engineering Plastics& Institute of Chemistry, National Natural Science Foundation of China (No. 51603189), China Postdoctoral Science Foundation (No. 2017M612000), Zhejiang Provincial Natural Science Foundation of China (No. LQ14C160004), and Scientific Research Foundation of Zhejiang A & F University (No. 2013FR088).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ru, J., Tong, C., Chen, N. et al. Morphological and property characteristics of surface-quaternized nanofibrillated cellulose derived from bamboo pulp. Cellulose 26, 1683–1701 (2019). https://doi.org/10.1007/s10570-018-2146-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-2146-z