Abstract

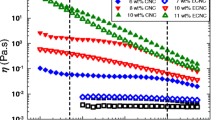

Rod-like cellulose nanocrystals (CNC) were incorporated into different systems containing polymers (most of them are soluble polysaccharides, such as chitosan, gum arabic, sodium alginate, hydroxypropyl methylcellulose and sodium carboxylmethyl cellulose) of varying charge properties and molecular structures. The dependence of the thickening and rheological behavior of CNC dispersion with concentration were compared with classic models for spheres. It is evident that rod-like particles are more effective in achieving viscosity enhancement at lower particle loading. By varying the concentrations of each polymeric system, the phase diagrams of non-absorbing and absorbing polymers were determined. The gelation behavior of anisotropic CNC dispersion in the presence of various kinds of polymers was investigated, and the thickening effect has the following trends: cationic > anionic > nonionic. In addition, the molecular weight and conformation of the polymer chains had an impact on the viscosity. Hydroxypropyl methylcellulose is the most effective in promoting gelation of 3 wt% CNC dispersion. Understanding the rheological properties of various CNC-polymer complexes will be critical for their application in oil and gas, food and consumer goods.

Graphical Abstract

Similar content being viewed by others

References

Aubry T, Largenton B, Moan M (1999) Rheological study of fumed silica suspensions in chitosan solutions. Langmuir 15(7):2380–2383

Balazs AC, Emrick T, Russell TP (2002) Nanoparticle polymer composites: where two small worlds meet. Science 314(5802):1107–1110

Boluk Y, Lahiji R, Zhao L et al (2011) Suspension viscosities and shape parameter of cellulose nanocrystals (CNC). Colloids Surfaces A Physicochem Eng Asp 377(1):297–303

Boluk Y, Zhao L, Incani V (2012) Dispersions of nanocrystalline cellulose in aqueous polymer solutions: structure formation of colloidal rods. Langmuir 28(14):6114–6123

Cassagnau P (2013) Linear viscoelasticity and dynamics of suspensions and molten polymers filled with nanoparticles of different aspect ratios. Polymer 54(18):4762–4775

Chang Y, McLandsborough L, McClements DJ (2014) Antimicrobial delivery systems based on electrostatic complexes of cationic ɛ-polylysine and anionic gum arabic. Food Hydrocoll 35:137–143

Derakhshandeh B, Petekidis G, Shafiei Sabet S et al (2013) Ageing, yielding, and rheology of nanocrystalline cellulose suspensions. J Rheol 57(1):131–148

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications Chem. Rev. 110(6):3479–3500

Hu Z, Cranston ED, Ng R et al (2014) Tuning cellulose nanocrystal gelation with polysaccharides and surfactants. Langmuir 30(10):2684–2692

Iwamoto S, Lee SH, Endo T (2014) Relationship between aspect ratio and suspension viscosity of wood cellulose nanofibers. Polym J 46(1):73–76

Jeong J, Li C, Kwon Y et al (2013) Particle shape effect on the viscosity and thermal conductivity of ZnO nanofluids. Int J Refrig 36(8):2233–2241

Khouri S, Shams M, Tam KC (2014) Determination and prediction of physical properties of cellulose nanocrystals from dynamic light scattering measurements. J Nanoparticle Res 16(7):2499

Li MC, Wu Q, Song K et al (2015) Cellulose nanoparticles: structure–morphology–rheology relationships. ACS Sustain Chem Eng 3(5):821–832

Liu D, Chen X, Yue Y et al (2011) Structure and rheology of nanocrystalline cellulose. Carbohyd Polym 84(1):316–322

Lu A, Hemraz U, Khalili Z et al (2014) Unique viscoelastic behaviors of colloidal nanocrystalline cellulose aqueous suspensions. Cellulose 21(3):1239–1250

Matheson RR Jr (1980) Viscosity of solutions of rigid rodlike macromolecules. Macromolecules 13(3):643–648

Oguzlu H, Danumah C, Boluk Y (2017) Colloidal behavior of aqueous cellulose nanocrystal suspensions. Curr Opin Colloid Interface Sci 29:46–56

Pang Q, Tang J, Huang H et al (2015) A nitrogen and sulfur dual-doped carbon derived from polyrhodanine@cellulose for advanced lithium–sulfur batteries. Adv Mater 27(39):6021–6028

Peng BL, Dhar N, Liu HL et al (2011) Chemistry and applications of nanocrystalline cellulose and its derivatives: a nanotechnology perspective. Can J Chem Eng 89(5):1191–1206

Qiao C, Chen G, Zhang J et al (2016) Structure and rheological properties of cellulose nanocrystals suspension. Food Hydrocoll 55:19–25

Reid MS, Villalobos M, Cranston ED (2017) The role of hydrogen bonding in non-ionic polymer adsorption to cellulose nanocrystals and silica colloids. Curr Opin Colloid Interface Sci 29:76–82

Risica D, Barbetta A, Vischetti L et al (2010) Rheological properties of guar and its methyl, hydroxypropyl and hydroxypropyl-methyl derivatives in semidilute and concentrated aqueous solutions. Polymer 51(9):1972–1982

Shafeiei-Sabet S, Hamad WY, Hatzikiriakos SG (2013) Influence of degree of sulfation on the rheology of cellulose nanocrystal suspensions. Rheol Acta 52(8–9):741–751

Shafiei-Sabet S, Hamad WY, Hatzikiriakos SG (2012) Rheology of nanocrystalline cellulose aqueous suspensions. Langmuir 28(49):17124–17133

Shafiei-Sabet S, Hamad WY, Hatzikiriakos SG (2014) Ionic strength effects on the microstructure and shear rheology of cellulose nanocrystal suspensions. Cellulose 21(5):3347–3359

Shi Z, Tang J, Chen L et al (2015) Enhanced colloidal stability and antibacterial performance of silver nanoparticles/cellulose nanocrystal hybrids. J Mater Chem B 3(4):603–611

Tan BH, Tam KC, Lam YC et al (2004) A semi-empirical approach for modeling charged soft microgel particles. J Rheol 48(4):915–926

Tan BH, Pelton RH, Tam KC (2010) Microstructure and rheological properties of thermo-responsive poly (N-isopropylacrylamide) microgels. Polymer 51(14):3238–3243

Tanaka R, Saito T, Ishii D et al (2014) Determination of nanocellulose fibril length by shear viscosity measurement. Cellulose 21(3):1581–1589

Tang J, Song Y, Berry RM et al (2014a) Polyrhodanine coated cellulose nanocrystals as optical pH indicators. RSC Adv 4(104):60249–60252

Tang J, Lee MFX, Zhang W et al (2014b) Dual responsive pickering emulsion stabilized by poly [2-(dimethylamino) ethyl methacrylate] grafted cellulose nanocrystals. Biomacromol 15(8):3052–3060

Tang J, Song Y, Tanvir S et al (2015a) Polyrhodanine coated cellulose nanocrystals: a sustainable antimicrobial agent. ACS Sustain Chem Eng 3(8):1801–1809

Tang J, Shi Z, Berry RM et al (2015b) Mussel-inspired green metallization of silver nanoparticles on cellulose nanocrystals and their enhanced catalytic reduction of 4-nitrophenol in the presence of β-cyclodextrin. Ind Eng Chem Res 54(13):3299–3308

Tang J, Berry RM, Tam KC (2016) Stimuli-responsive cellulose nanocrystals for surfactant-free oil harvesting. Biomacromol 17(5):1748–1756

Tang J, Sisler J, Grishkewich N et al (2017) Functionalization of cellulose nanocrystals for advanced applications. J Colloid Interface Sci 494:397–409

ten Brinke AJW, Bailey L, Lekkerkerker HNW et al (2007) Rheology modification in mixed shape colloidal dispersions. Part I: pure components. Soft Matter 3(9):1145–1162

Tzoumaki MV, Moschakis T, Biliaderis CG (2011) Mixed aqueous chitin nanocrystal–whey protein dispersions: microstructure and rheological behavior. Food Hydrocoll 25(5):935–942

Tzoumaki MV, Moschakis T, Biliaderis CG (2013) Effect of soluble polysaccharides addition on rheological properties and microstructure of chitin nanocrystal aqueous dispersions. Carbohydr Polym 95(1):324–331

Ureña-Benavides EE, Ao G, Davis VA et al (2011) Rheology and phase behavior of lyotropic cellulose nanocrystal suspensions. Macromolecules 44(22):8990–8998

Wu Q, Meng Y, Wang S et al (2014) Rheological behavior of cellulose nanocrystal suspension: influence of concentration and aspect ratio. J Appl Polym Sci 131(15):40525

Acknowledgments

K. C. Tam would like to acknowledge the support from CFI and NSERC.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Peng, B., Tang, J., Wang, P. et al. Rheological properties of cellulose nanocrystal-polymeric systems. Cellulose 25, 3229–3240 (2018). https://doi.org/10.1007/s10570-018-1775-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1775-6