Abstract

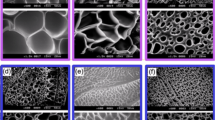

Phase separation of polymer solutions initiated by the addition of a nonsolvent is the main method for the preparation of polymer membranes. Depending on the application, such membranes must have a different pore size, which depends on the numerous parameters of the forming process. The liquid–liquid phase separation has been considered for cellulose solutions in N-methylmorpholine N-oxide (NMMO) interacting with various alcohols (methyl, ethyl, isopropyl, and isobutyl). Kinetics of cellulose regeneration was investigated by laser interferometry technique to understand the mechanism of cellulose film structure formation in the NMMO process. Influence of temperature, coagulant nature, and cellulose content on the process kinetics and morphology of the films was studied and corresponding interdiffusion coefficients were calculated. Based on the solubility parameters, triple phase diagrams of the systems were calculated. Formation of different morphologies was explained primarily by the different position of the composition path, the bimodal curve, and the gelation line in the phase diagrams. The second important parameter was the different rate of mutual diffusion of the NMMO and coagulants, due to the difference in the viscosity of the latter. Using methanol or ethanol as coagulation baths leads to obtaining the nanoporous structure of cellulose films, whereas isopropanol and isobutanol favors macropore formation.

Similar content being viewed by others

References

Abe Y, Mochizuki A (2002) Hemodialysis membrane prepared from cellulose/N-methylmorpholine-N-oxide solution. I. Effect of membrane preparation conditions on its permeation characteristics. J Appl Polym Sci 84:2302–2307

Abe Y, Mochizuki A (2003) Hemodialysis membrane prepared from cellulose/N-methylmorpholine-N-oxide solution. II. Comparative studies on the permeation characteristics of membranes prepared from N-methylmorpholine-N-oxide and cuprammonium solutions. J Appl Polym Sci 89:333–339

Anderson JE, Ullman R (1973) Mathematical analysis of factors influencing the skin thickness of asymmetric reverse osmosis membranes. J Appl Phys 44:4303–4311

Bang YH, Lee S, Park JB, Cho HH (1999) Effect of coagulation conditions on fine structure of regenerated cellulosic films made from cellulose/N-methylmorpholine-N-oxide/H2O systems. J Appl Polym Sci 73(13):2681–2690

Biganska O, Navard P (2005) Kinetics of precipitation of cellulose from cellulose–NMMO–water solutions. Biomacromolecules 6:1948–1953

Biganska O, Navard P (2009) Morphology of cellulose objects regenerated from cellulose–N-methylmorpholine N-oxide–water solutions. Cellulose 16:179–188

Boltzmann L (1894) Zur Integration der Diffusionsgleichung bei variabeln Diffusionscoefficienten. Ann Phys 289(13):959–964

Budtova T, Navard P (2016) Cellulose in NaOH–water based solvents: a review. Cellulose 23(1):5–55

Cai J, Wang L, Zhang L (2007) Influence of coagulation temperature on pore size and properties of cellulose membranes prepared from NaOH–urea aqueous solution. Cellulose 14:205–215

Cho J, Amy G, Pellegrino J (2000) Membrane filtration of natural organic matter: factors and mechanisms affecting rejection and flux decline with charged ultrafiltration (UF) membrane. J Membr Sci 164(1):89–110

Dawsey TR, McCormick CL (1990) The lithium chloride/dimethylacetamide solvent for cellulose: a literature review. J Macromol Sci Rev Macromol Chem Phys 30(3–4):405–440

Fink HP, Weigel P, Purz HJ, Ganster J (2001) Structure formation of regenerated cellulose materials from NMMO-solutions. Progr Polym Sci 26(9):1473–1524

Fink HP, Ganster J, Lehmann A (2014) Progress in cellulose shaping: 20 years industrial case studies at Fraunhofer IAP. Cellulose 21:31–51

Gao J, Tang LG (1999) Cellulose science. Science Publ. Comp, Beijing

Gavillon R, Budtova T (2007) Kinetics of cellulose regeneration from cellulose–NaOH–water gels and comparison with cellulose–N-methylmorpholine-N-oxide–water Solutions. Biomacromolecules 8:424–432

Golova LK (1996) Processing of cellulose via highly concentrated “solid solutions. Fibre Chem 28(1):5–16

Golova LK, Kulichikhin VG, Papkov SP (1986) Mechanism of dissolution of cellulose in non-aqueous dissolving systems. Review Polym Sci USSR 28(9):1995–2011

Hansen CM (2007) Hansen solubility parameters: a user’s handbook, 2nd edn. CRC Press, Boca Raton

Hauru LK, Hummel M, King AW, Kilpeläinen I, Sixta H (2012) Role of solvent parameters in the regeneration of cellulose from ionic liquid solutions. Biomacromolecules 13(9):2896–2905

Ichwan M, Son TW (2012) Preparation and characterization of dense cellulose film for membrane application. J Appl Polym Sci 124(2):1409–1418

Ilyin SO, Makarova VV, Anokhina TS, Volkov AV, Antonov SV (2017) Effect of coagulating agent viscosity on the kinetics of formation, morphology, and transport properties of cellulose nanofiltration membranes. Polym Sci Ser A 59(5):676–684

Jie X, Cao Y, Lin B, Yuan Q (2004) Gas permeation performance of cellulose hollow fiber membranes made from the cellulose/N-methylmorpholine-N-oxide/H2O system. J Appl Polym Sci 91(3):1873–1880

Krigbaum WR, Carpenter DK (1954) Phase equilibria in polymer–liquid 1–liquid 2 systems. J Polym Sci 14(75):241–259

Kulichikhin VG, Golova LK, Makarov IS, Bondarenko GN, Berkovich AK, Ilyin SO (2016) Cellulose–co-polyacrylonitrile blends: properties of combined solutions in N-metylmorpholine-N-oxide and the formation and thermolysis of composite fibers. Polym Sci Ser C 58(1):74–84

Laity PR, Glover PM, Hay JN (2002) Composition and phase changes observed by magnetic resonance imaging during non-solvent induced coagulation of cellulose. Polymer 43(22):5827–5837

Li HJ, Cao YM, Qin JJ, Jie XM, Wang TH, Liu JH, Yuan Q (2006) Development and characterization of anti-fouling cellulose hollow fiber UF membranes for oil–water separation. J Membr Sci 279(1):328–335

Liu S, Zhang L (2009) Effects of polymer concentration and coagulation temperature on the properties of regenerated cellulose films prepared from LiOH/urea solution. Cellulose 16(2):189–198

Lu Y, Wu Y (2008) Influence of coagulation bath on morphology of cellulose membranes prepared by NMMO method. Front Chem Sci Eng 2:204–208

Mackie JS, Meares P (1955) The diffusion of electrolytes in a cation-exchange resin membrane. I. Theoretical. Proc R Soc Lond Ser A 232:498–509

Makarova V, Kulichikhin V (2011) Application of interferometry to analysis of polymer–polymer and polymer–solvent interactions. In: Padron I (ed) Interferometry—research and applications in science and technology. InTech, Rijeka, pp 395–436

Malkin A, Askadsky A, Chalykh A, Kovriga V (1983) Experimental methods of polymer physics. Mir Publishers, Moscow

Malkin A, Ilyin S, Roumyantseva T, Kulichikhin V (2012) Rheological evidence of gel formation in dilute poly (acrylonitrile) solutions. Macromolecules 46(1):257–266

Mantanis GI, Young RA, Rowell RM (1995) Swelling of compressed cellulose fiber webs in organic liquids. Cellulose 2(1):1–22

Mao Y, Zhou J, Cai J, Zhang L (2006) Effects of coagulants on porous structure of membranes prepared from cellulose in NaOH/urea aqueous solution. J Membr Sci 279(1):246–255

Mao Z, Cao Y, Jie X, Kang G, Zhou M, Yuan Q (2010) Dehydration of isopropanol–water mixtures using a novel cellulose membrane prepared from cellulose/N-methylmorpholine-N-oxide/H2O solution. Sep Purif Technol 72(1):28–33

Marcus Y (1993) The properties of organic liquids that are relevant to their use as solvating solvents. Chem Soc Rev 22(6):409–416

Matano C (1933) On the relation between the diffusion-coefficients and concentrations of solid metals (the nickel-copper system). Jpn J Appl Phys 8(3):109–113

Olsson C, Westman G (2013) Direct dissolution of cellulose: background, means and applications. In: van de Ven T, Godbout L (eds) Cellulose—fundamental aspects. Intech, Rijeka, pp 143–178

Otero JA, Mazarrasa O, Villasante J, Silva V, Pradanos P, Calvo JI, Hernandez A (2008) Three independent ways to obtain information on pore size distributions of nanofiltration membranes. J Membr Sci 309:17–27

Pan ML, Li WJ, Wang MR, You C (2012) Preparation of the reed cellulose membrane by using NMMO Method. Adv Mater Res 538:128–131

Pinkert A, Marsh KN, Pang S, Staiger MP (2009) Ionic liquids and their interaction with cellulose. Chem Rev 109(12):6712–6728

Robinson JP, Tarleton ES, Millington CR, Nijmeijer A (2004) Solvent flux through dense polymeric nanofiltration membranes. J Membr Sci 230:29–37

Rosenau T, Potthast A, Sixta H, Kosma P (2001) The chemistry of side reactions and byproduct formation in the system NMMO/cellulose (lyocell process). Progr Polym Sci 26(9):1763–1837

Scott RL (1949) The thermodynamics of high polymer solutions. IV. Phase equilibria in the ternary system: polymer–liquid 1–liquid 2. J Chem Phys 17(3):268–279

Sescousse R, Budtova T (2009) Influence of processing parameters on regeneration kinetics and morphology of porous cellulose from cellulose–NaOH–water solutions. Cellulose 16:417–426

Shokri J, Adibkia K (2013) Application of cellulose and cellulose derivatives in pharmaceutical industries. In: van de Ven T, Godbout L (eds) Cellulose—medical, pharmaceutical and electronic applications. InTech, Rijeka. https://doi.org/10.5772/55178

Singh S, Khulbe KC, Matsuura T, Ramamurthy P (1998) Membrane characterization by solute transport and atomic force microscopy. J Membr Sci 142:111–127

Tsar’kov SE, Malakhov AO, Litvinova EG, Volkov AV (2013) Nanofiltration of dye solutions through membranes based on poly(trimethylsilylpropyne). Petrol Chem 53(7):537–545

Uddin AJ, Yamamoto A, Gotoh Y, Nagura M, Iwata M (2010) Preparation and physical properties of regenerated cellulose fibres from sugarcane bagasse. Text Res J 80(17):1846–1858

van de Witte P, Dijkstra PJ, van den Berg JWA, Feijen J (1996) Phase separation processes in polymer solutions in relation to membrane formation. J Membr Sci 117:1–31

van der Bruggen B, Mänttäri M, Nyström M (2008) Drawbacks of applying nanofiltration and how to avoid them: a review. Sep Purif Technol 63:251–263

Willberg-Keyriläinen P, Hiltunen J, Ropponen J (2018) Production of cellulose carbamate using urea-based deep eutectic solvents. Cellulose 25:195–204

Wu J, Yuan Q (2002) Gas permeability of a novel cellulose membrane. J Membr Sci 204(1):185–194

Xiong X, Duan J, Zou W, He X, Zheng W (2010) A pH-sensitive regenerated cellulose membrane. J Membr Sci 363(1):96–102

Yushkin AA, Anokhina TS, Volkov AV (2015) Application of cellophane films as nanofiltration membranes. Petrol Chem 55(9):746–752

Zhang Y, Shao H, Wu C, Hu X (2001) Formation and characterization of cellulose membranes from N-methylmorpholine-N-oxide solution. Macromol Biosci 1(4):141–148

Acknowledgments

This research was supported by the Russian Science Foundation (Project No. 14-19-01775).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ilyin, S.O., Makarova, V.V., Anokhina, T.S. et al. Diffusion and phase separation at the morphology formation of cellulose membranes by regeneration from N-methylmorpholine N-oxide solutions. Cellulose 25, 2515–2530 (2018). https://doi.org/10.1007/s10570-018-1756-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1756-9